is a possible source of color inaccuracy. You can eliminate the possibility by performing a color

calibration (see Color calibration on page 143).

●

ICC prole. If you are using the wrong prole, your colors are likely to be inaccurate. Check which prole

you are using. If necessary, you can make your own ICC prole for the printer, printheads, print mode,

and substrate that you are using.

●

Ink density, which aects color saturation. If the color saturation of your print seems wrong, try

changing the ink density in the substrate preset; you may need to change the number of passes at the

same time.

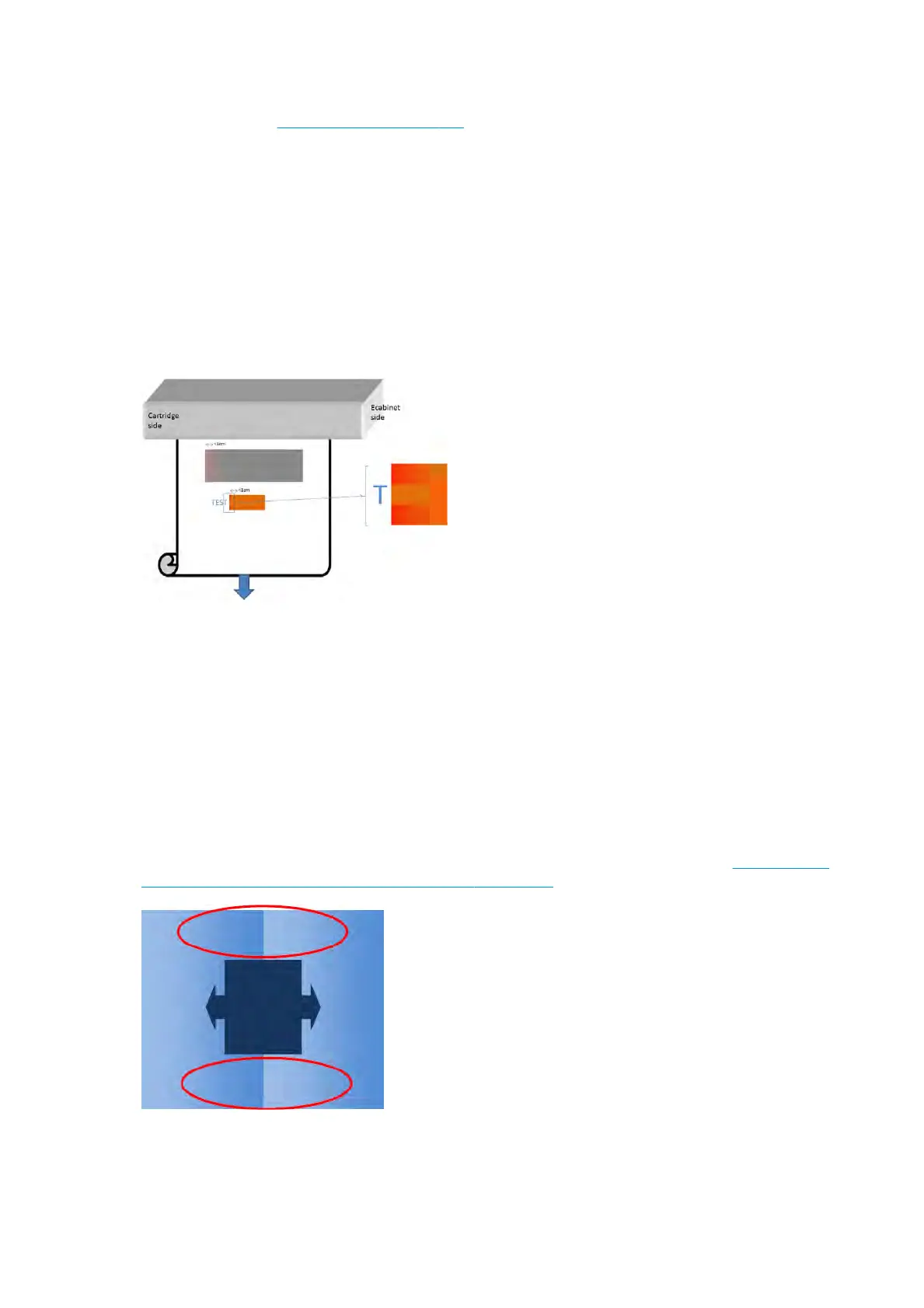

Local color variations

In some cases, at the edges of area lls, a small number of ink drops may be missing or slightly darker,

producing a local color variation.

These defects are due to the printheads travelling from side to side without printing.

●

In e

ach pass, the rst 1 or 2 drops of a color are missing or smaller.

●

In each pass, the rst 1 or 2 drops of a color are darker because they are more concentrated with

pigment.

To resolve these defects, add spit bars at each side of the image, to make sure nozzles are refreshed before

printing each pass. If possible, you could also rotate the image to avoid situations such as shown in the

example.

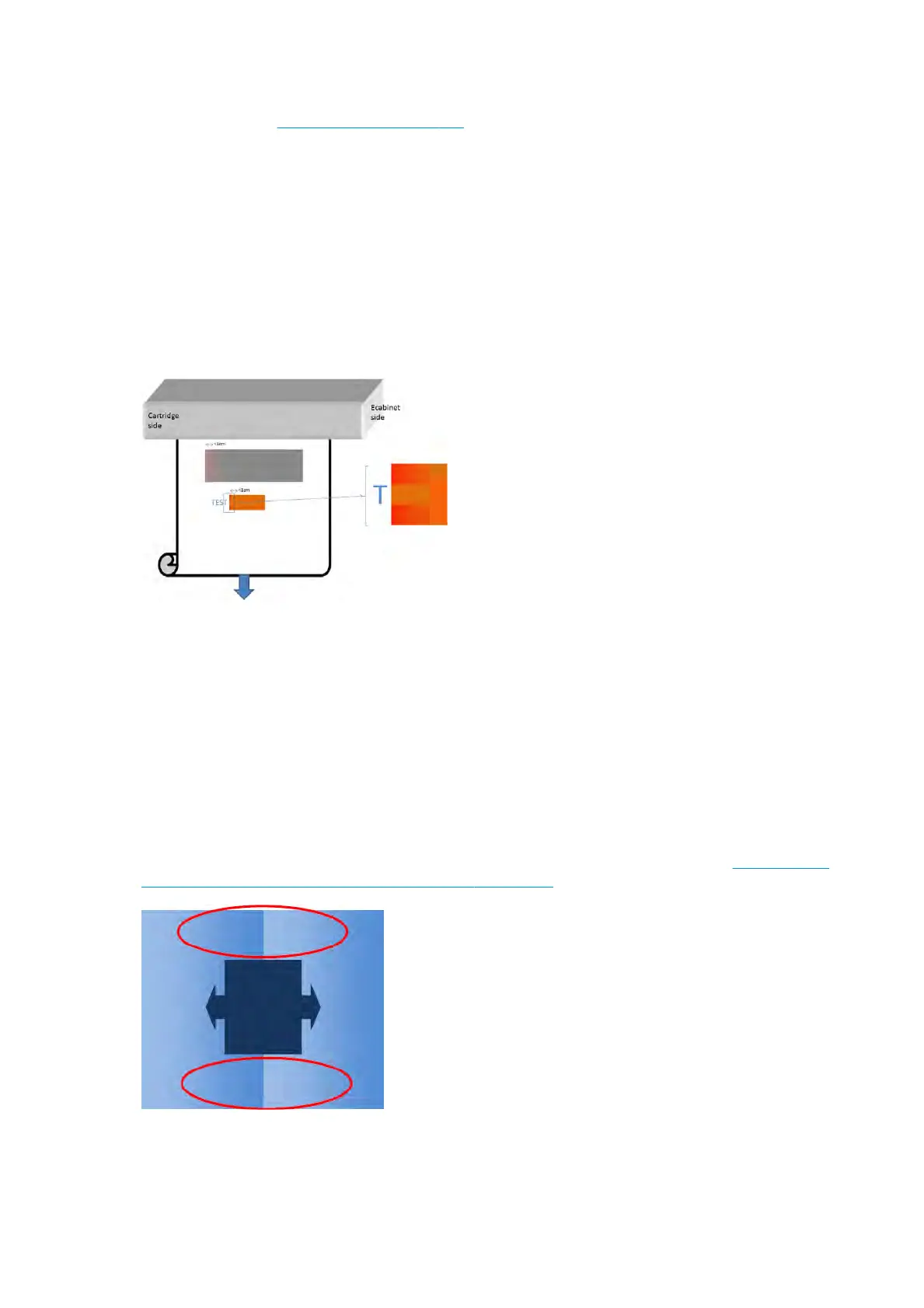

Color variations when tiling

When tiling, it is important that all tiles have the same length and that the colors of the mating edges match.

This section focuses on color variations; for recommendations about length consistency, see

How to achieve

better consistency between jobs of the same length on page 310.

326 Chapter 10 Troubleshoot print-quality issues ENWW

Loading...

Loading...