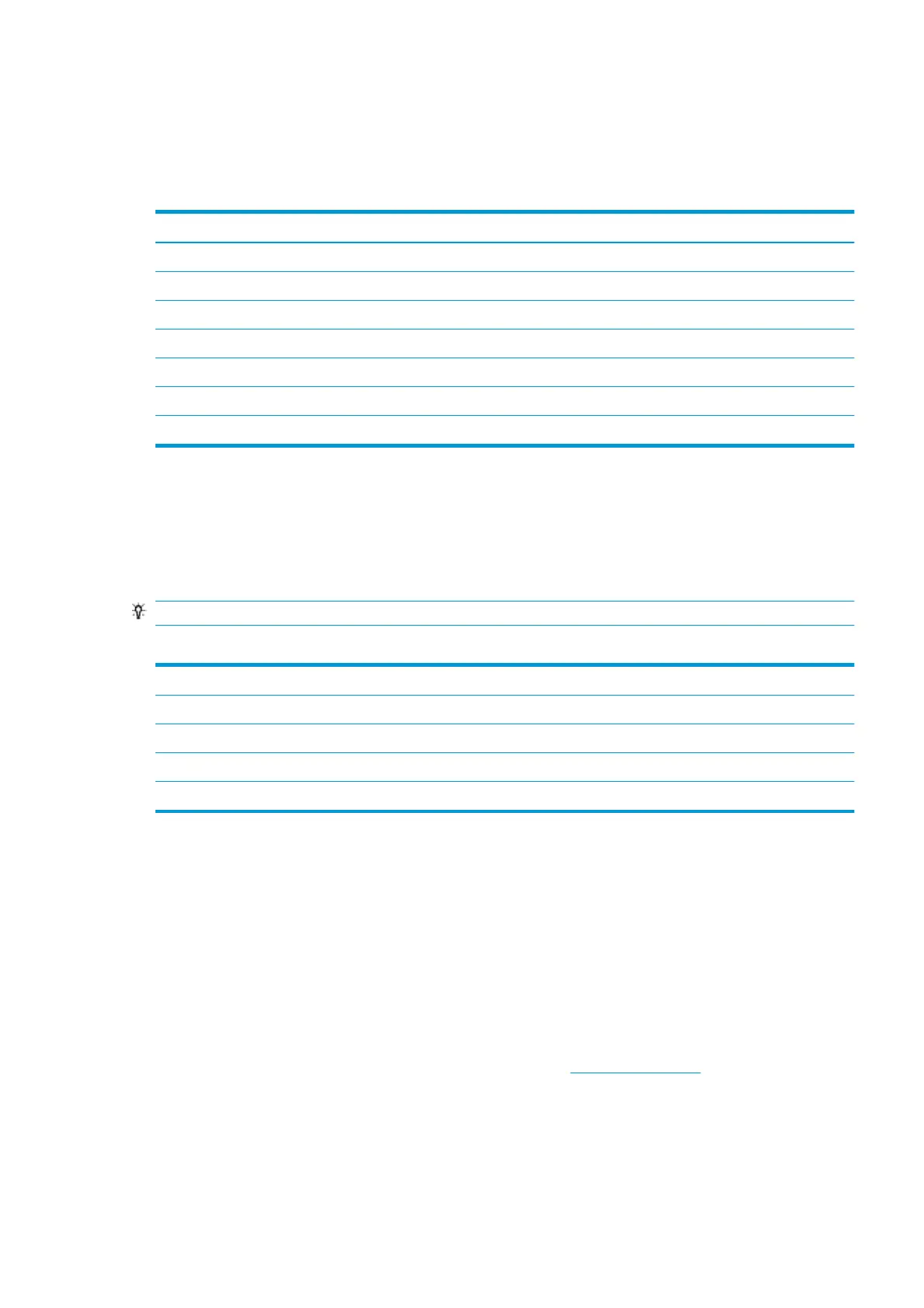

Power specications

The drying and curing components are powered with a three-phase line that requires a power distribution

unit (PDU).

Table 14-7 Power specications for drying and curing components

HP Latex 3000 HP Latex 3100 / 3500

Mains power, input rated current

3-phase (line-to-line voltage) 200–240 V AC (±10%), 50/60 Hz, 48 A max 200–240 V AC (±10%), 50/60 Hz, 56 A max

3-phase (line-to-line voltage) 380–415 V AC (±10%), 50/60Hz, 30 A max 380–415 V AC (±10%), 50/60Hz, 35 A max

High-current 1-phase 240 V AC (±10%), 50/60Hz, 63 A max 240 V AC (±10%), 50/60Hz, 72 A max

PC power (optional), input rated current

1-phase 100–127 V AC (±10%), 50/60Hz, 6 A max 100–127 V AC (±10%), 50/60Hz, 10 A max

1-phase 200–240 V AC (±10%), 50/60Hz, 6 A max 200–240 V AC (±10%), 50/60Hz, 10 A max

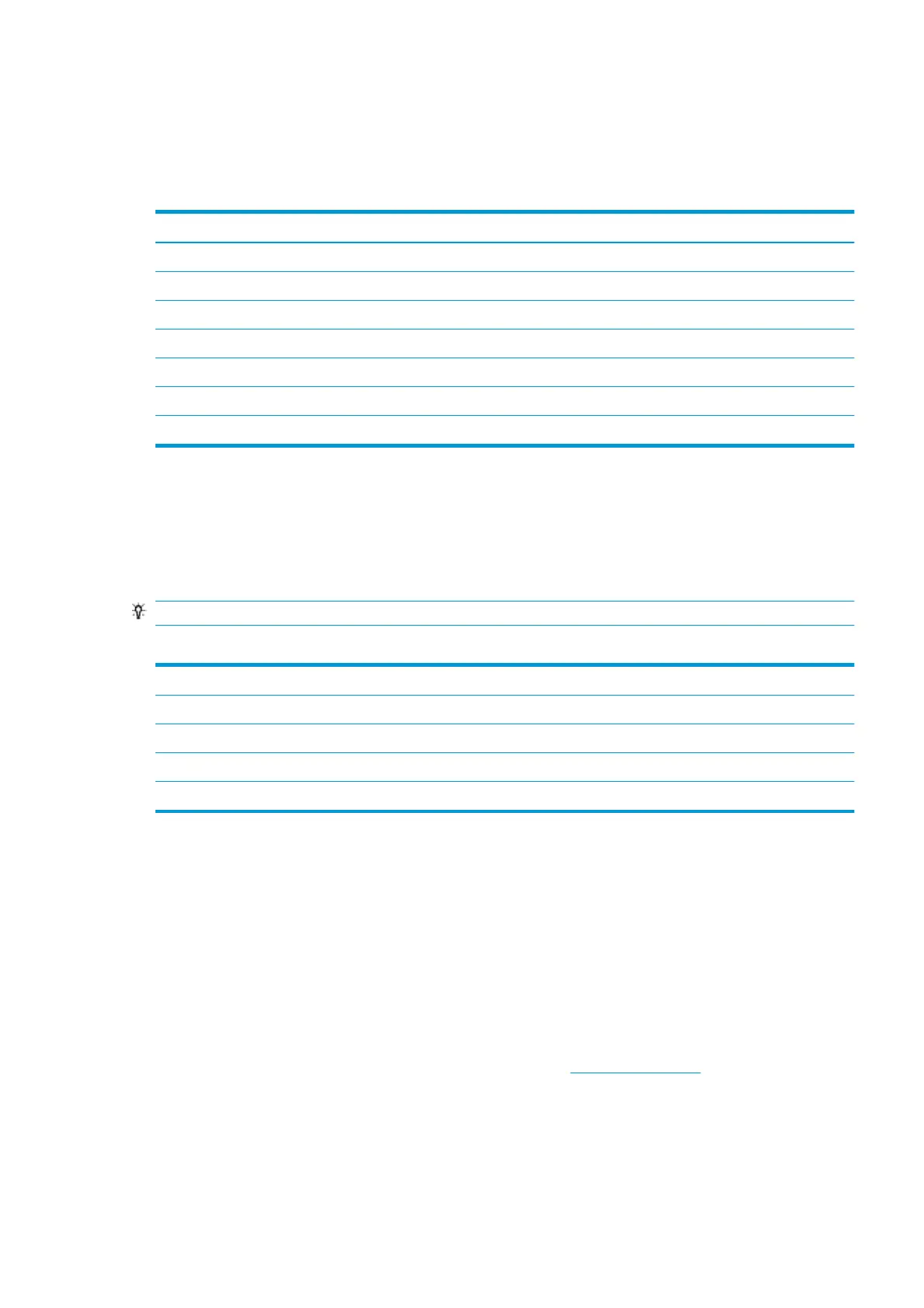

Air supply requirements (pneumatic spindle)

Air pressure supply

The pneumatic spindle requires an air compressor or a pressurized air line, not supplied with the printer.

TIP: You are recommended to use a pressure gauge that indicates the pressure in bars.

Table 14-8 Air supply specications

Air pressure 5.5 bar (80 psi)

Minimum airow Recommendation: 30 l/min

Lubricator Not recommended

Air lter (recommended) Recommendation: 5 µm, auto-drain, 99.97% coalescing eciency

Regulator (required) Regulator with pressure gauge

Pneumatic connector

The printer comes with an air gun that you must attach to your air supply. In order to connect your air supply

to the air gun, you must meet the following requirements:

●

9.84-mm (0.25-in) female connector, BSP or NPT thread

●

Tape to secure the connection and prevent air leaks

Ecological specications

For the up-to-date ecological specications of your printer, go to http://www.hp.com/ and search for

“ecological specications”.

ENWW Power specications 345

Loading...

Loading...