3. Check that you are using the generic substrate preset for the substrate category. The use of incorrect

values could cause incorrect substrate behavior.

4. Reload the substrate and try to minimize skew while loading. Check that you are loading the substrate

using the correct procedure.

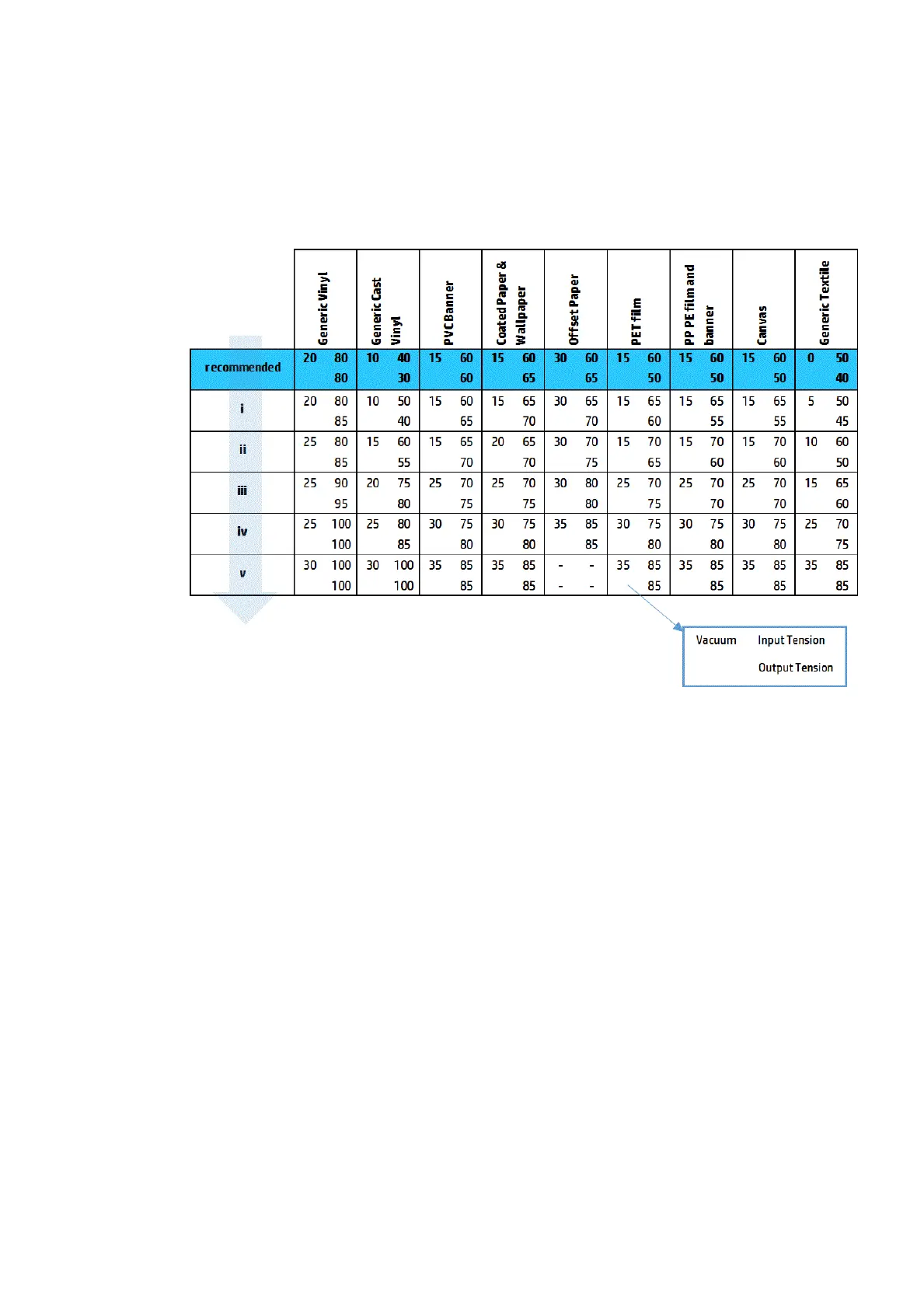

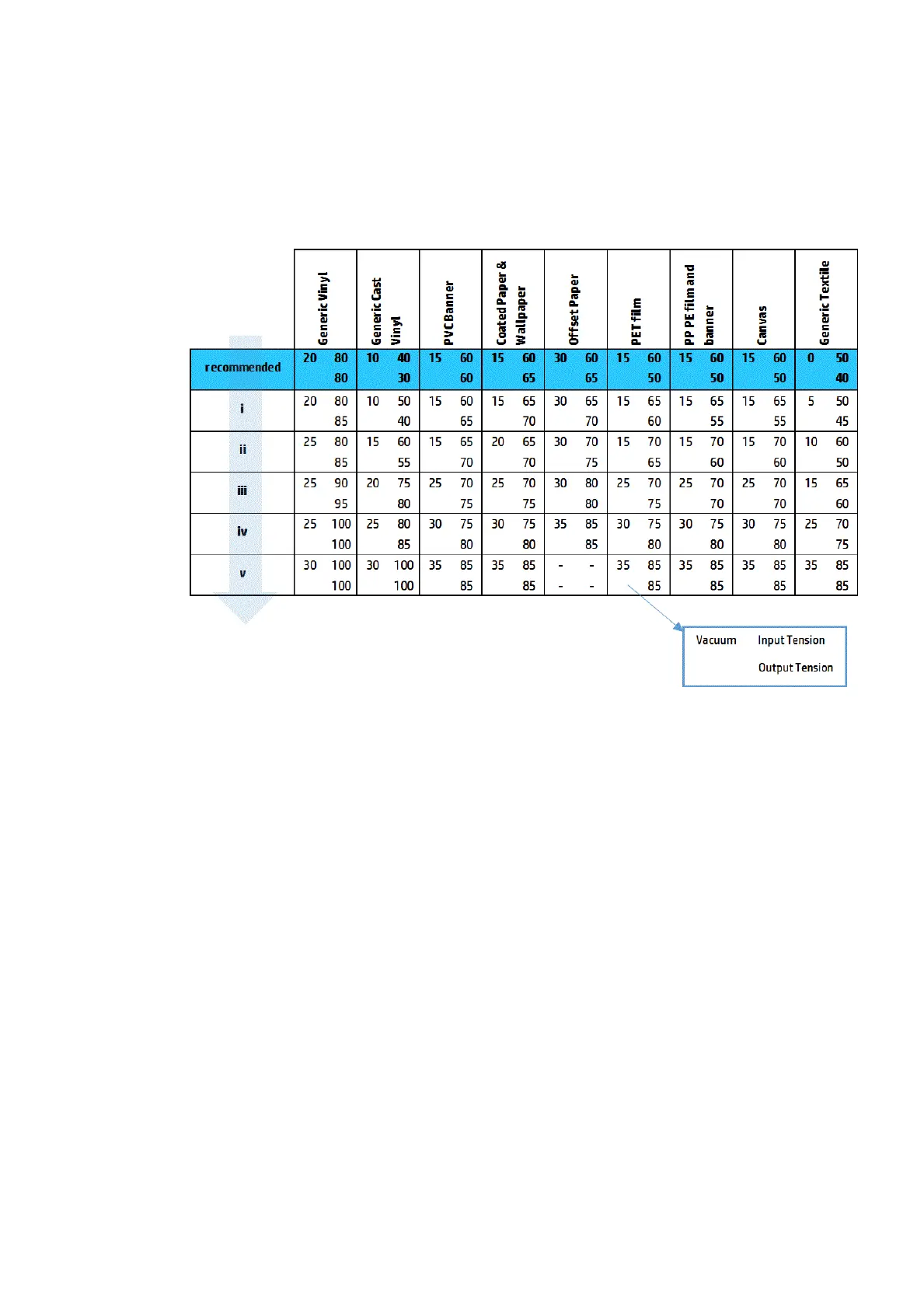

5. Increase vacuum and tensions step by step (i to v) following the table below, until you nd settings that

work.

There are physical marks on the substrate

This onl

y can occur when substrates sensitive to permanent deformation are used. These marks are usually

seen in isolated areas and mainly caused by high curing temperature or substrate tensions.

Here are some suggested ways to correct the problem:

1. Check that the substrate you are using is the same type as the one you have selected in the Internal

Print Server.

2. Check that you are using the generic substrate preset for the substrate category. The use of incorrect

values could cause incorrect substrate behavior.

3. Reload the substrate and try to minimize skew while loading. Check that you are loading the substrate

using the correct procedure.

4. Try to reduce curing temperature and ink quantity if possible, and raise the curing airow to help in

reducing the substrate deformation.

ENWW Printing issues 303

Loading...

Loading...