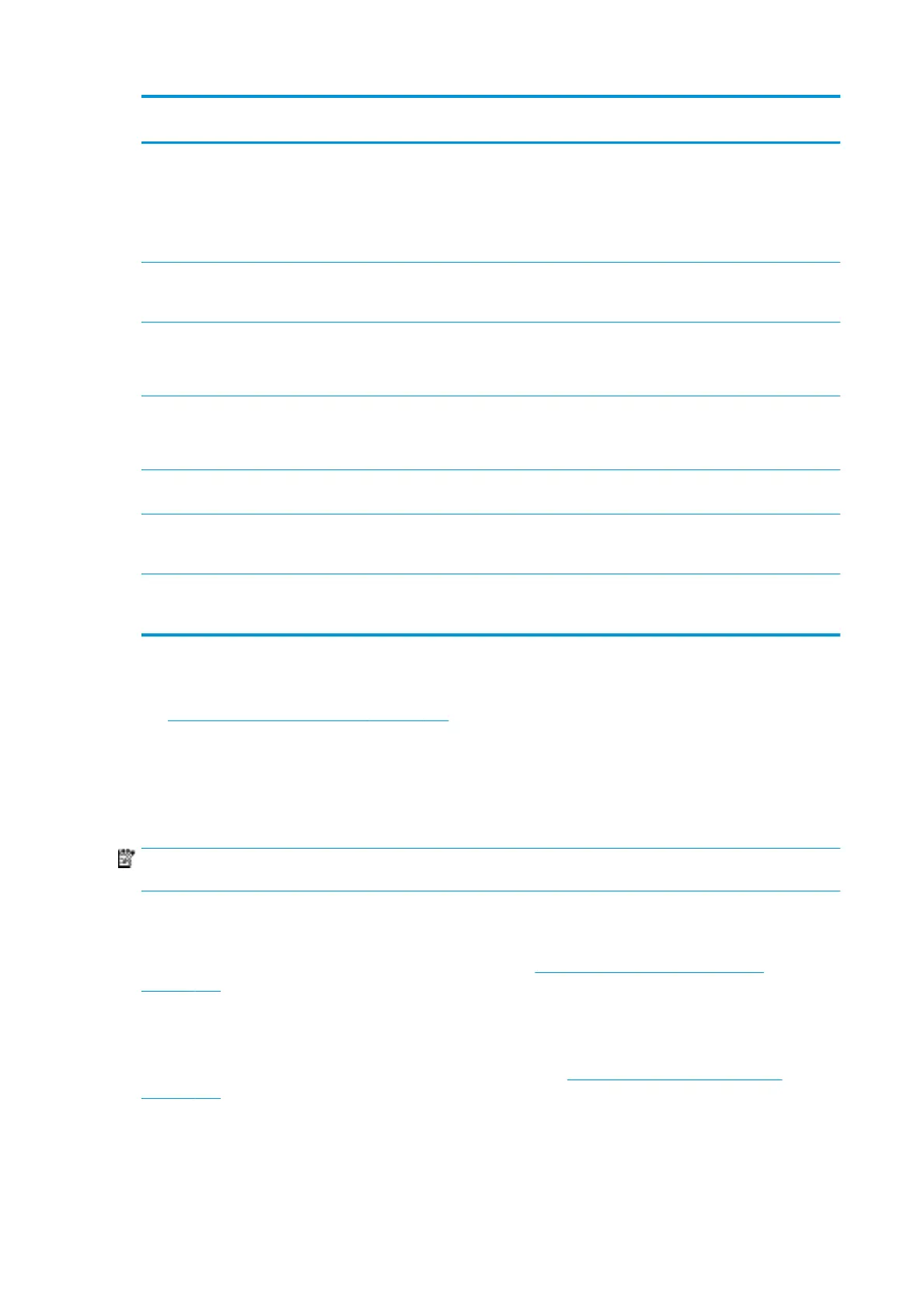

Defect Printhead check and

clean

Substrate-advance

sensor check

Printhead alignment Possible causes (for

reference only)

Banding X X X

●

B

locked nozzles

●

Substrate advance

accuracy

●

Intra-color

alignment

Isolated bands (usually

o

f dierent texture or

grain)

X

●

Subs

trate-advance

accuracy and

navigability

Graininess X X

●

Substrate advance

accuracy

●

Color alignment

Blurry edges or text

line

s, horizontally

X X

●

Subs

trate advance

accuracy

●

Color alignment

Blurry edges or text

line

s, vertically

X

●

C

olor alignment

Color halo on objects

(

e.g., magenta shows up

under a blue line)

X

●

C

olor alignment

Ink bleeding, wicking, or

dierent

gloss at the

edges of color areas

X

●

Op

timizer

alignment

Printhead check and clean

See Check and clean the printheads on page 122. The check and clean process will check the printheads,

recover the ones with blocked nozzles, and replace the nozzles that are not recovered with healthy ones for

printing.

Substrate-advance sensor check

Run the OMAS Diagnostic Test from the HP Print Care window.

NOTE: OMAS stands for Optical Media Advance Sensor, usually known as the substrate-advance sensor in

this guide.

The test will tell you whether the substrate-advance sensor is working correctly or not (either dirty or

damaged).

If the substrate-advance sensor is dirty, clean the sensor. See Clean the substrate-advance sensor

on page 231.

Even if the sensor is working correctly, the substrate may not be navigable, meaning that the substrate-

advance sensor cannot see it properly (as in the case of transparent substrates or substrates with very

smooth back side). In this case, the substrate-advance sensor disables itself automatically. You are then

recommended to adjust the substrate-advance compensation: see Substrate-advance compensation

on page 146.

For best results, cleaning the substrate-advance sensor is included in the printer’s weekly maintenance.

316 Chapter 10 Troubleshoot print-quality issues ENWW

Loading...

Loading...