◦

In

tra-color alignment (alignment between the two printheads of the same color)

◦

Inter-color alignment (alignment between dierent colors)

Her

e are some tips for solving this problem:

◦

If the printhead alignment was done with a dierent substrate of dierent thickness, probably a

new printhead alignment is needed.

◦

Fine-tune the alignment by identiying the oenders in the printhead alignment diagnostics plot.

See Alignment procedure on page 137.

●

Substrate advance. Before trying to adjust any parameter, make the following checks:

◦

Check that no substrate-advance factor was set earlier that could prevent the substrate-advance

sensor from working correctly.

◦

Run the diagnostics to check that that the substrate-advance sensor is not dirty.

If the substrate advance is not well adjusted, particularly if it is over-advancing, a white line can appear

between passes.

A clear symptom of this is when the white lines appear across all colors, because the cause is common to

all of them. To conrm it, in the Internal Print Server, select Printer > Advance Calibration to check the

substrate advance. See Substrate-advance test print on page 147.

You can usually correct this problem by adjusting the substrate advance compensation (see Substrate-

advance compensation on page 146). However, you are recommended to run the OMAS Diagnostic Tests

from the Print Care window as soon as the substrate is unloaded, to avoid having the same problem with

other substrates. See Clean the substrate-advance sensor on page 231.

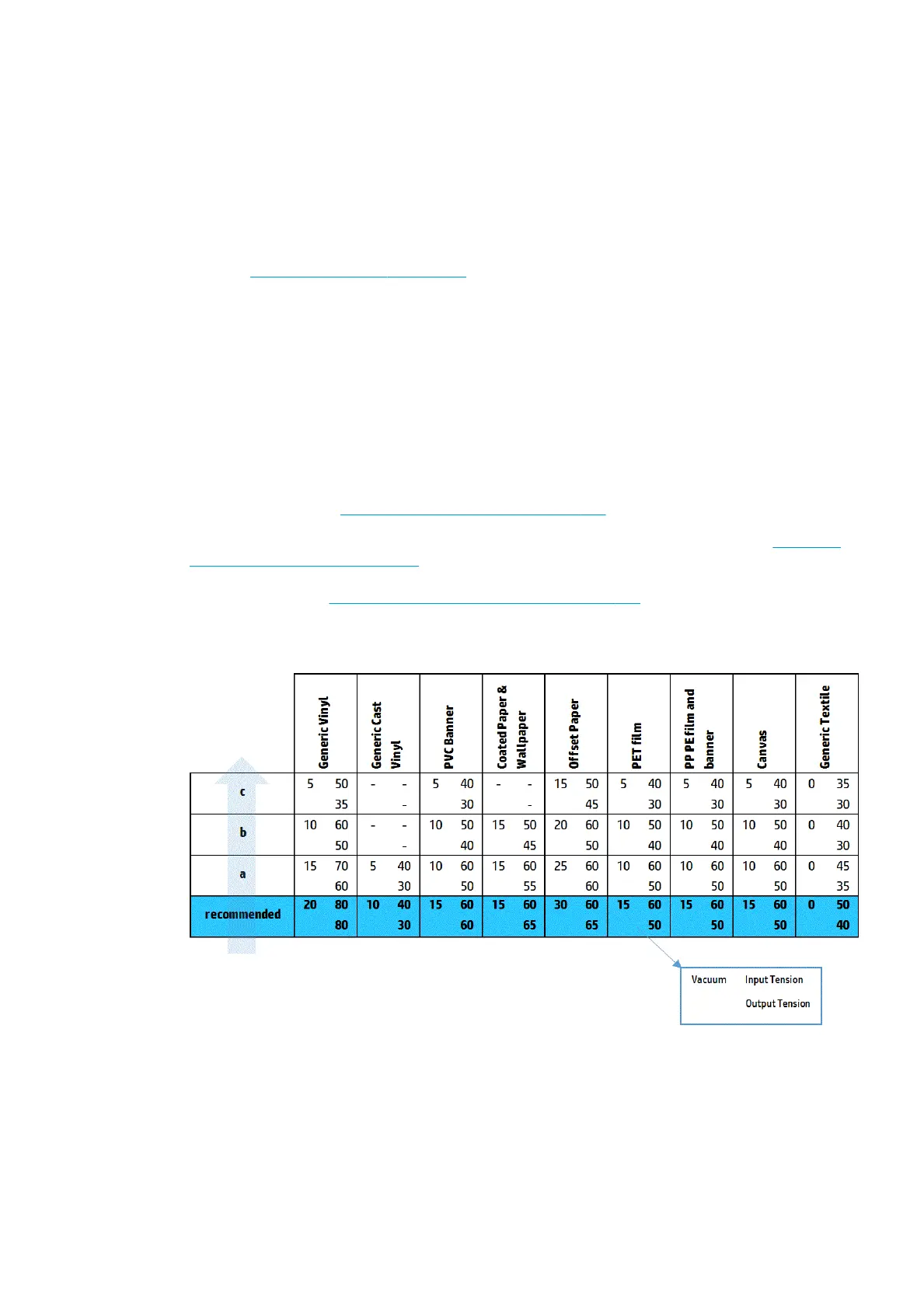

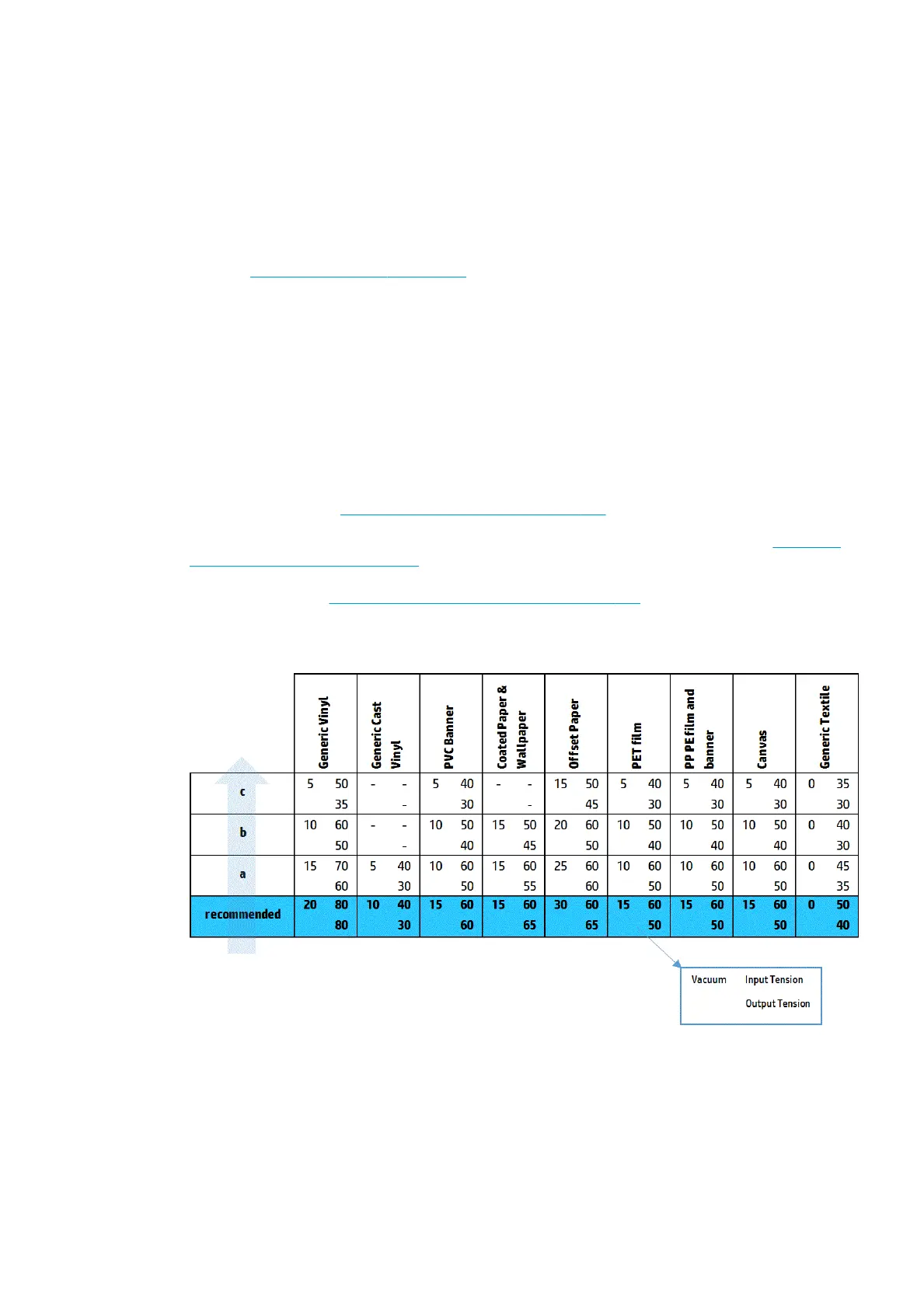

If the problem persists, try adjusting tension and vacuum settings according to the table below, step by

step (a to c), until you nd settings that work.

Bands of light and dark zones

These are periodic horizontal bands formed of a lighter band and a consecutive darker band. This pattern is

mostly seen in solid color area lls (such as light purple or gray).

ENWW Advanced print-quality troubleshooting 319

Loading...

Loading...