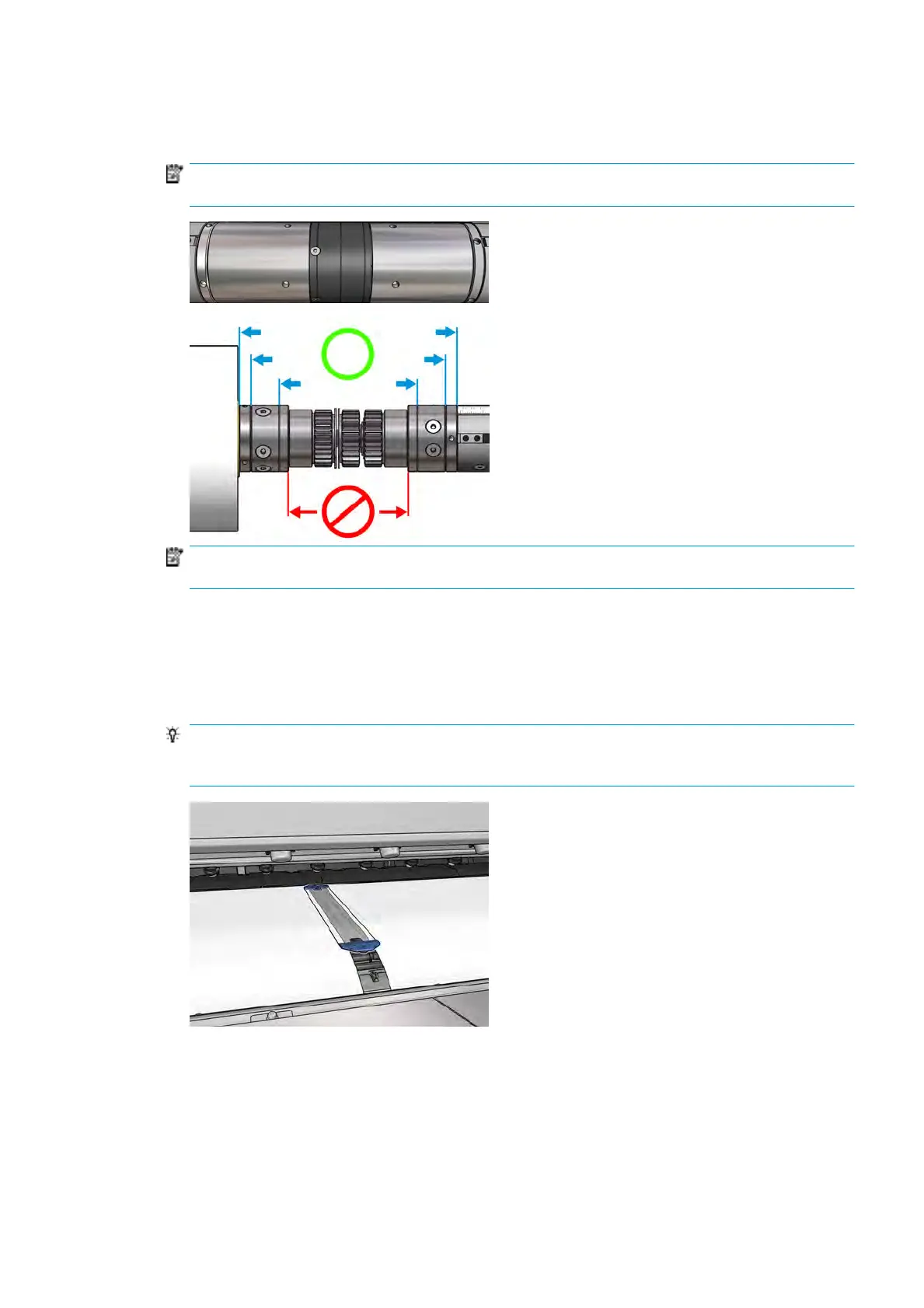

10. Align the substrate by checking that the substrate edge is in the same position on the input and output

spindles. This can be done by using the rulers on the spindles or by measuring the distance between the

right edge and the side plate.

NOTE: You are recommended to align the edges of both rolls by the lines on both sides of the spindle’s

center mark.

NOTE: The subs

trate-advance sensor must be covered by the substrate (from 252 to 310 cm on the

ruler).

11. When the subs

trate is evenly tensioned and at (no wrinkles or bumps), attach it to each empty core

with adhesive tape. Tape it rst in the center, and then at the left and right sides, making sure not to pull

the substrate excessively or leave it wrinkled.

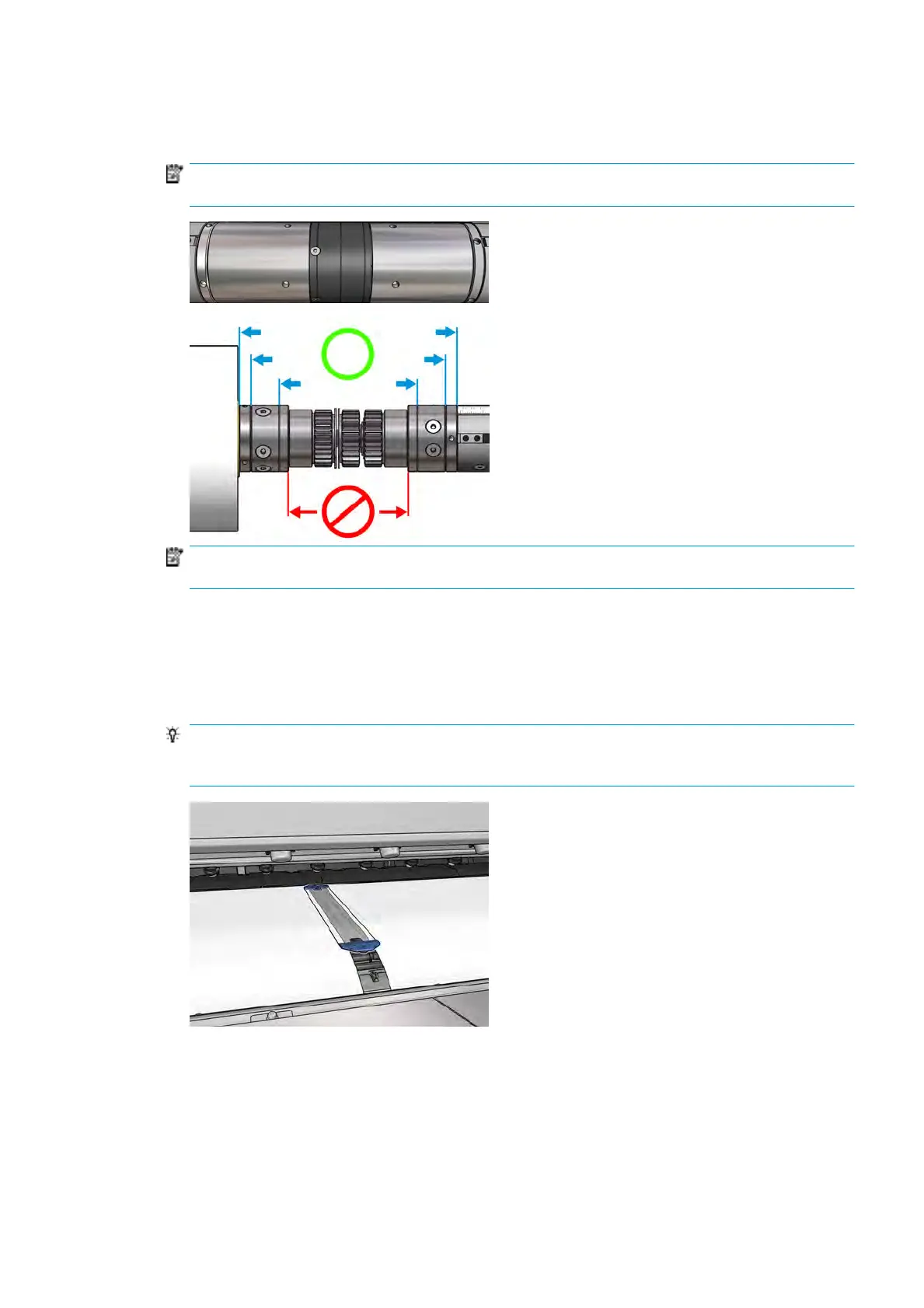

12. If you are using them, place the three or four substrate edge holders into position and attach them at

the front.

TIP: HP Latex 3000/3100 only: When aligning the roll edges with the marks on the dual-roll spindle,

the center edge holder (if needed) is shared by both rolls. If you position the rolls dierently, and you are

using edge holders, take into account the distance required for the edge holders.

13. Cl

ose the front door and the curing module.

14. If you are using them, attach the substrate edge holders at the rear.

15. Close the loading table.

ENWW Load a roll into the printer 67

Loading...

Loading...