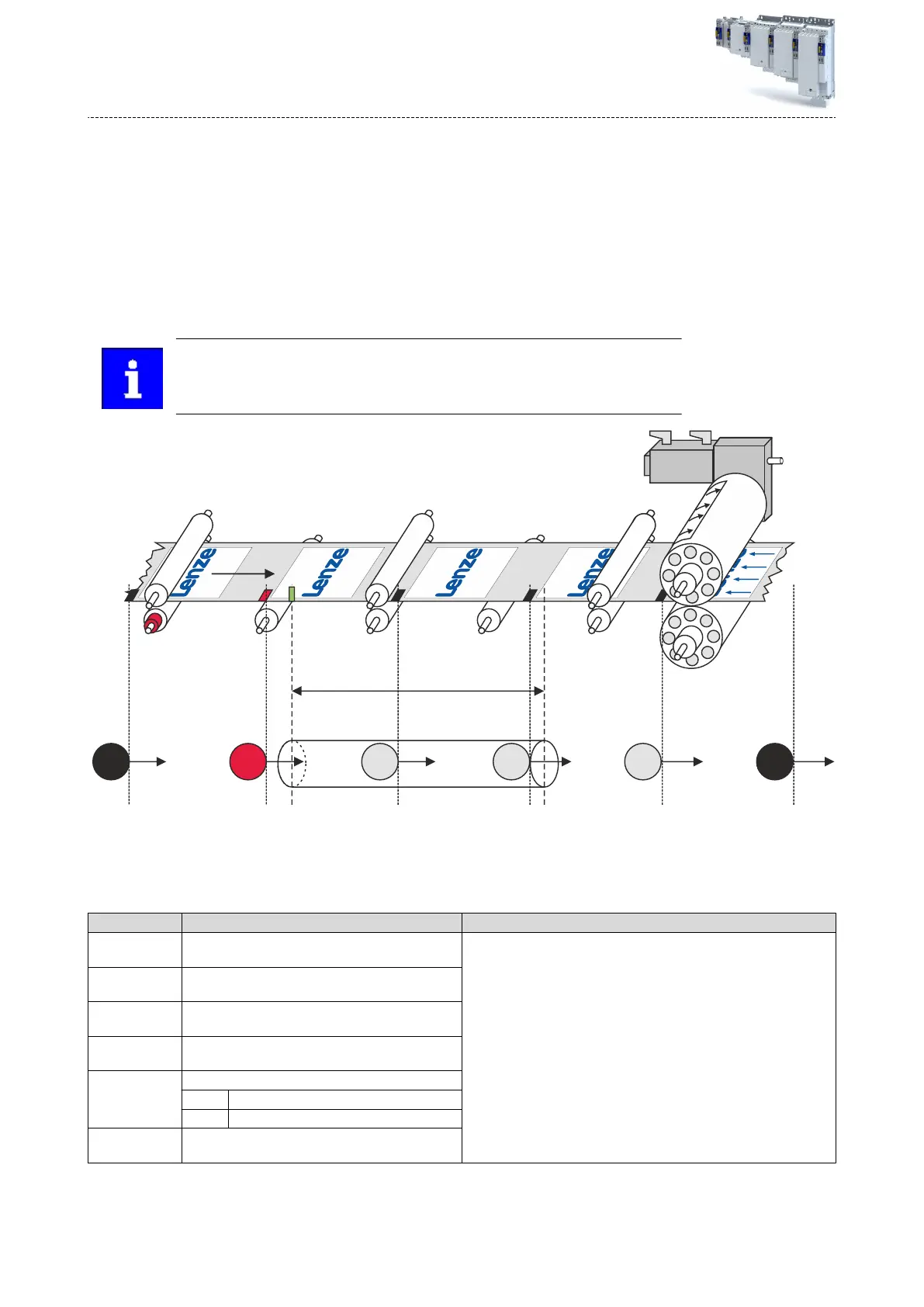

If, due to the design, the mark sensor is posioned farther away from the tool than a mark

dis

tance, detected marks are automacally stored in a mark stack. The length of the stack is

such that the mark leaves the stack one cycle (mark distance) in front of the tool and triggers a

"virtual" touch probe. Aerwards the mark error is calculated. This ensures that the master

value is always corrected at the right me.

Master distances

•

Sensor distance 40x5041:001

•

Marking distance40x5041:002

If the detected mark is in cycle with the tool, it is evaluated. This means the mark sensor is

virtually set to the posion exactly one cycle in front of the tool.

Mount the mark sensor a maximum of 64 cycles in front of the tool.

Fig. 60: Systemac

representaon of the mark register

Mount the mark sensor as close as possible to the tool. The further from the axis the mark

sensor is mounted, the more imprecise the cuts will be.

Parameter

Address Name / seng range / [default seng] Info

0x5041:001 Sensor distance

0.0000 ... [360.0000] ... 214748.3647

0x5041:002 Mark distance

0.0000 ... [360.0000] ... 214748.3647

0x5041:008 Mark window size

0.0000 ... [40.0000] ... 214748.3647

0x5041:009 Mark window oset

0.0000 ... [0.0000] ... 214748.3647

0x5041:013 Acvate master value

correcon

false O

true On

0x5042:001 Sensor set posion

•

R

ead only

Conguring the "Sync and Correcon" TA

Mas

ter value correcon (register control)

Mark window and mark register

138

Loading...

Loading...