13.5.3.1 Basic seng

The following parameters must be set for the acvaon and basic seng of the holding brake

c

ontrol.

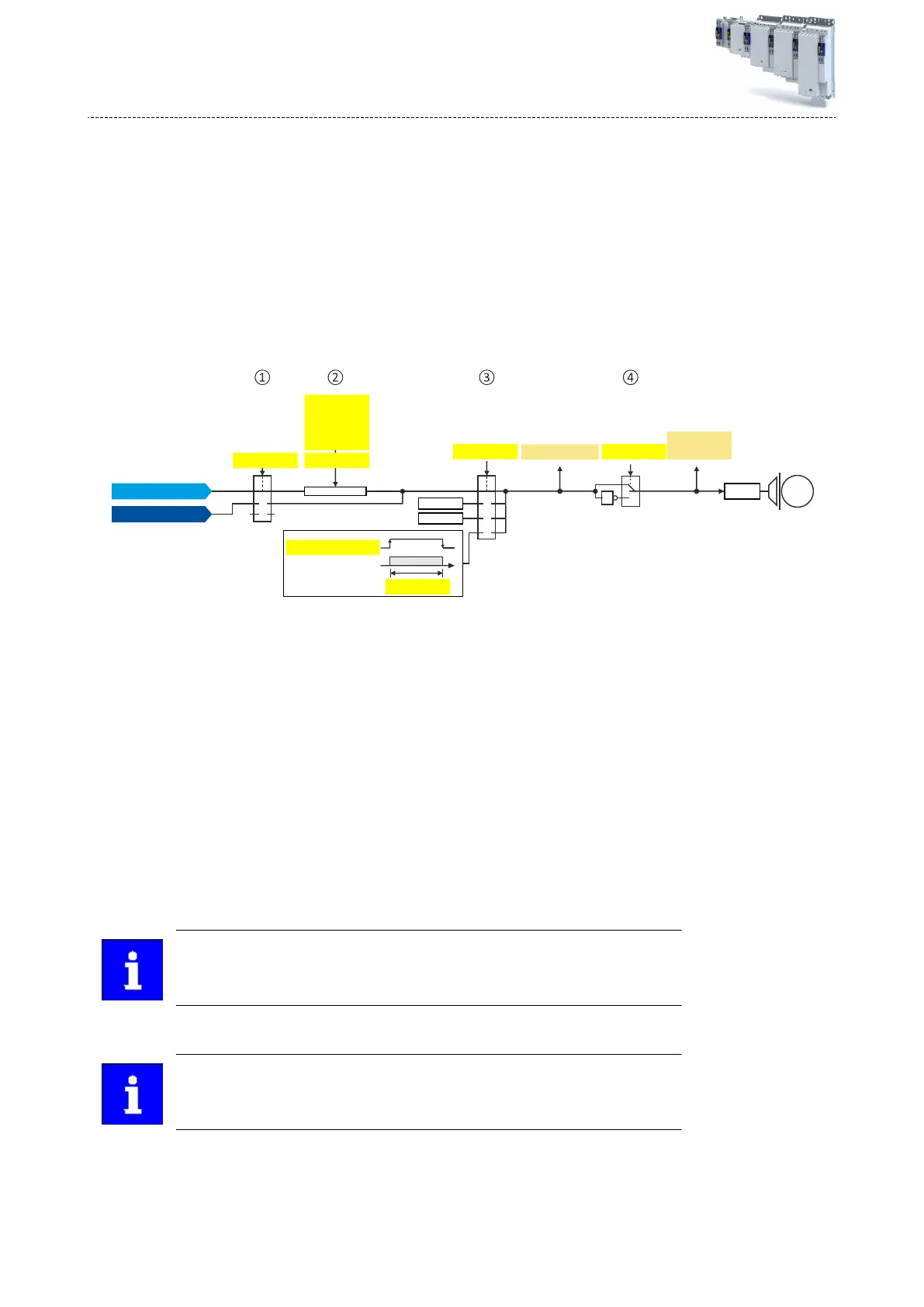

Details

The following sengs are possible:

•

Brake mode

①

•

For the automac

operaon:

②

-

Br

ake release me and brake applicaon me

-

T

orque feedforward control

•

Test Brake control

③

•

Brake polarity

④

Device status

0x2820:020, Bit 1

t

0x2820:019

1

0

Start

Stop

0x2820:021

0x2820:010

0x2820:009

0x2820:003

0x2820:002

0x2820:015

0x2820:004

0x6040:000, Bit16

Auto

0x2820:001

1

0

2

1

0

1

X106

0x2820:005

0x6041, Bit 14

2

3

0x2820:011

1

0

M

Diagnosc parameters:

•

Displa

y status of the automac brake idencaon: 0x2820:004

•

Display signal of the brake logic before the inversion: 0x6041

•

Display status of the holding brake: 0x2820:015

Brake mode

Possible sengs: 0x2820:001

•

Manual control via the control word. Das control word depends on the technology applica-

on :

•

Technology applicaon CiA 402: 0x6040 Bit 14

•

Speed Control technology applicaon: 0x5030:010 Bit 14

•

0: Close holding brake

•

1: Release holding brake

•

Control via device state machine (automac operaon):

-

The holding br

ake is controlled as a funcon of the device state.

-

A t

orque feedforward control is possible.

The torque is precontrolled for one second. During this me, the actual torque

mus

t have reached 90 % of the setpoint torque, otherwise an error is triggered.

-

R

esponse mes of the holding brake during release and applicaon can be compensa-

t

ed for.

In the event of an error or when STO ("SafeTorqueO") is acvated, the brake is

applied immedia

tely without considering the set brake applicaon me. The

inverter immediately changes to the switch-on disabled state.

•

No br

ake connected (o):

-

holding brake control, automac brake idencaon and brake monitoring are deac-

vated.

Conguring the motor control

P

arameterisable motor funcons

Holding brake control

254

Loading...

Loading...