16.3.1.2 Restarng or stopping the communicaon

A restart of

communicaon is required aer changes of the interface conguraon (e. g. sta-

on address and IP conguraon) in order that the changed sengs become eecve with-

out switching the mains.

4Staon name and IP conguraon ^ 358

For restarng the communicaon, there are two opons:

•

0x2380 = 1 (r

estart with current values).

•

0x2380 must be set = 2 (restart with the values saved last).

The following opon can be used to stop communicaon:

•

0x2380 must be set = 5 (stop network communicaon).

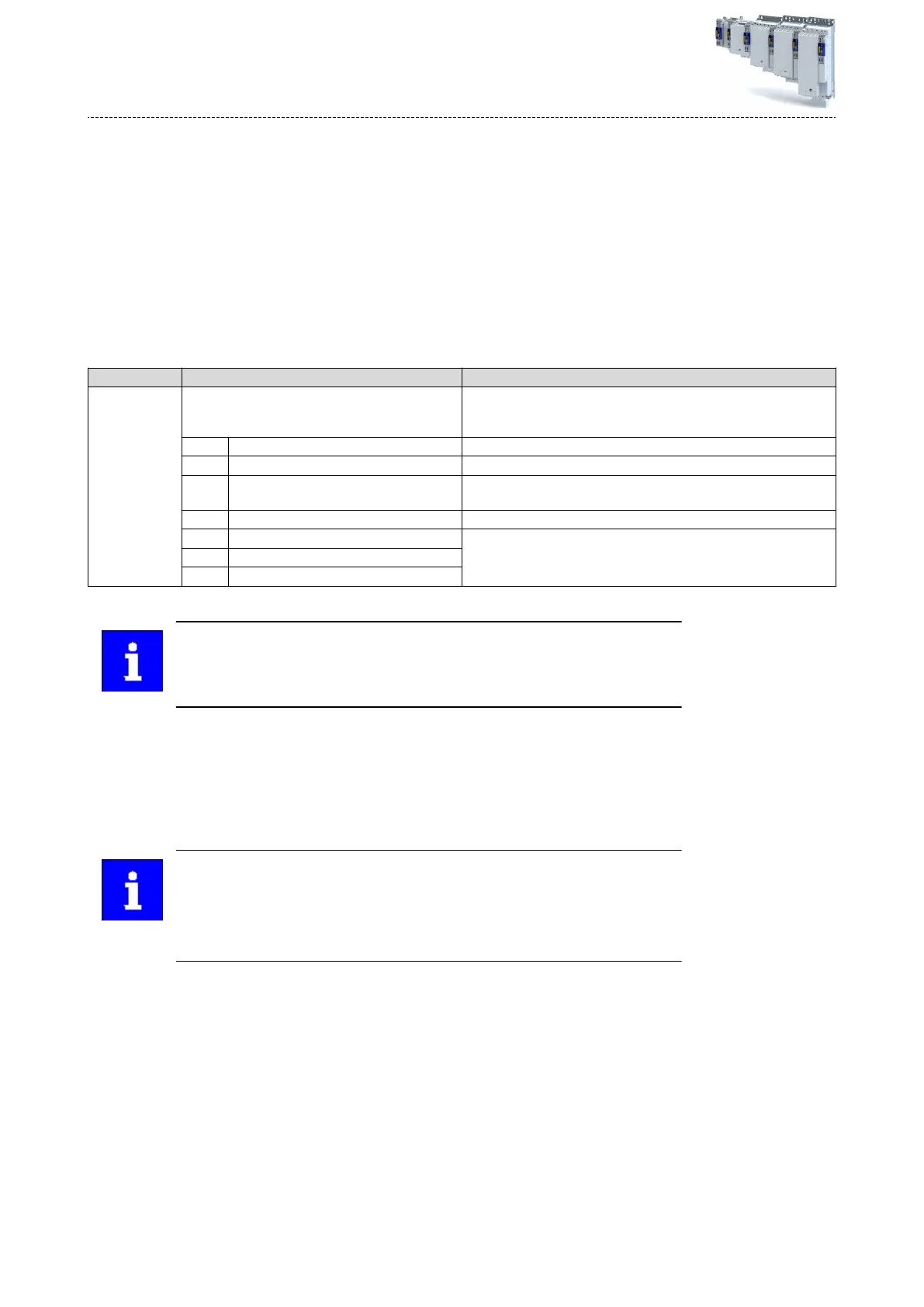

Parameter

Address Name / seng range / [default seng] Info

0x2380 PROFINET communicaon Restart / stop

communicaon

•

When the de

vice command has been executed successfully, the value

0 is shown.

0 No acon/no error Only status feedback

1 Restart with current values Restart communicaon with the current values.

2 Restart with default values Restart communicaon with the values of the PROFINET parameters that

ha

ve been saved last (0x2381:001 ... 0x2381:009).

5 Stop network communicaon Stop communicaon

10 In process Only status feedback

11 Acon cancelled

12 Fault

16.3.1.3 Sengs in the Siemens »TIA Portal«

Here, commissioning with the Siemens »TIA Portal« is described. Please note

tha

t in the standard seng of the Siemens »TIA Portal« changes of network

parameters carried out by a Lenze engineering tool (e. g. »EASY Starter«) may

be overwrien.

1.Go to the device conguraon and open the "net view" to drag the inverter from the cata-

log to the net view of the PROFINET.

2.Assign the inverter to the associated IO-Controller.

3.Mark the inverter and change to the "device view".

4.Set the IP address and the staon name ("PROFINET device name") in "Properes".

See: 4

Staon name and IP conguraon

In order that the inverter can be idened via Ethernet when the IO controller is

s

witched o, the staon name and the IP conguraon must be saved in the

inverter with mains failure protecon via the separate entry with the »EASY

Starter«. 0x2022:003

See: 4Saving the parameter sengs ^

36

5.Below the device name and the name of the device descripon le, the device view shows

the pr

e-assignment of output and input process data words.

In slot 1, pre-assigned process data words can be changed.

When using PROFIsafe, you can add safety process data in slot 2.

4PROFIsafe ^ 365

6.Save the project in the engineering tool.

7.Load the conguraon into the IO-Controller.

8.Set the IO-Controller to "RUN".

Conguring the network

PR

OFINET

Commissioning

356

Loading...

Loading...