MaintenanceInstructions

Out-of-roundtiresandwheelassembliescansometimesbe

correctedbyreclockingthetirerelativetothewheel.

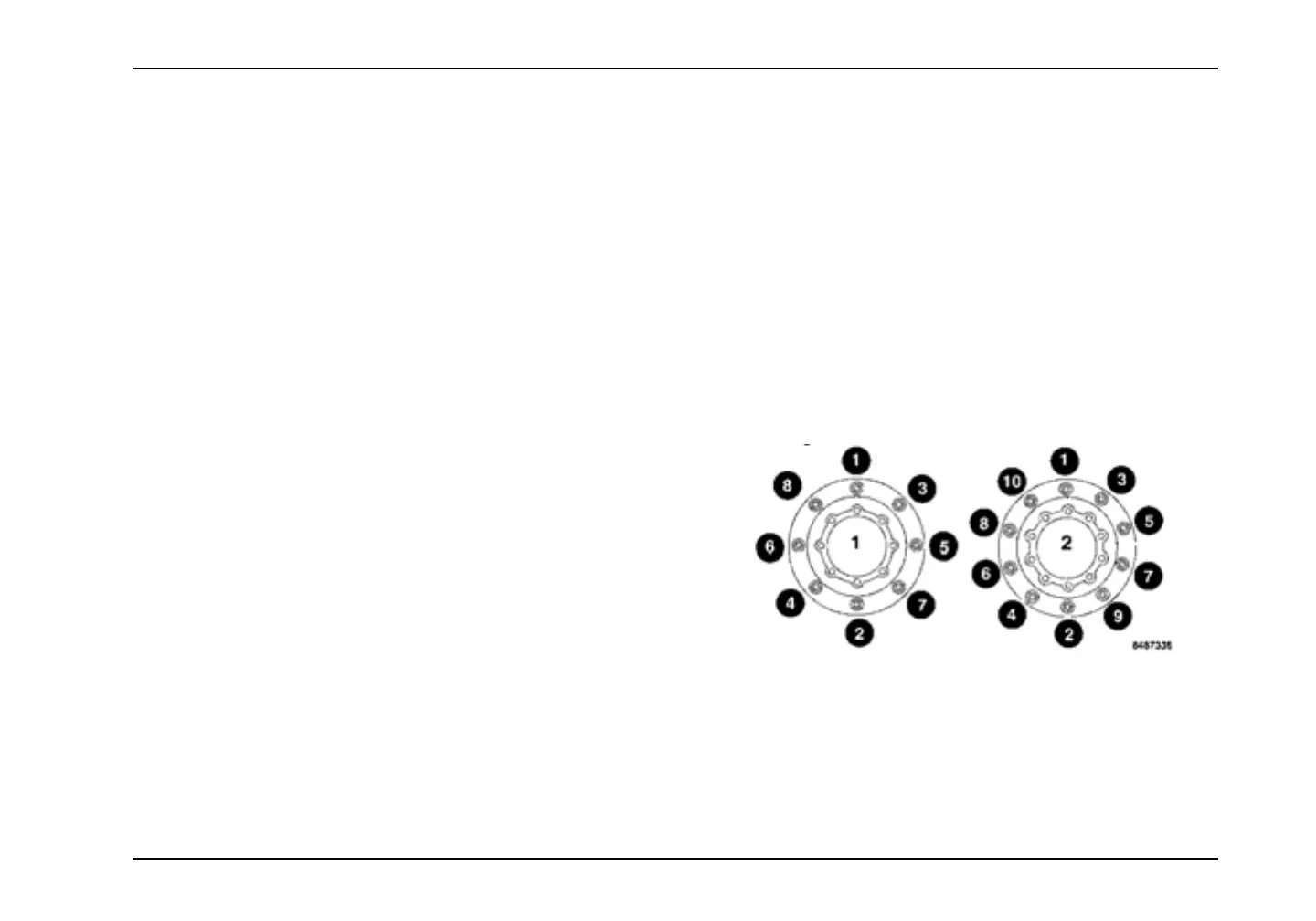

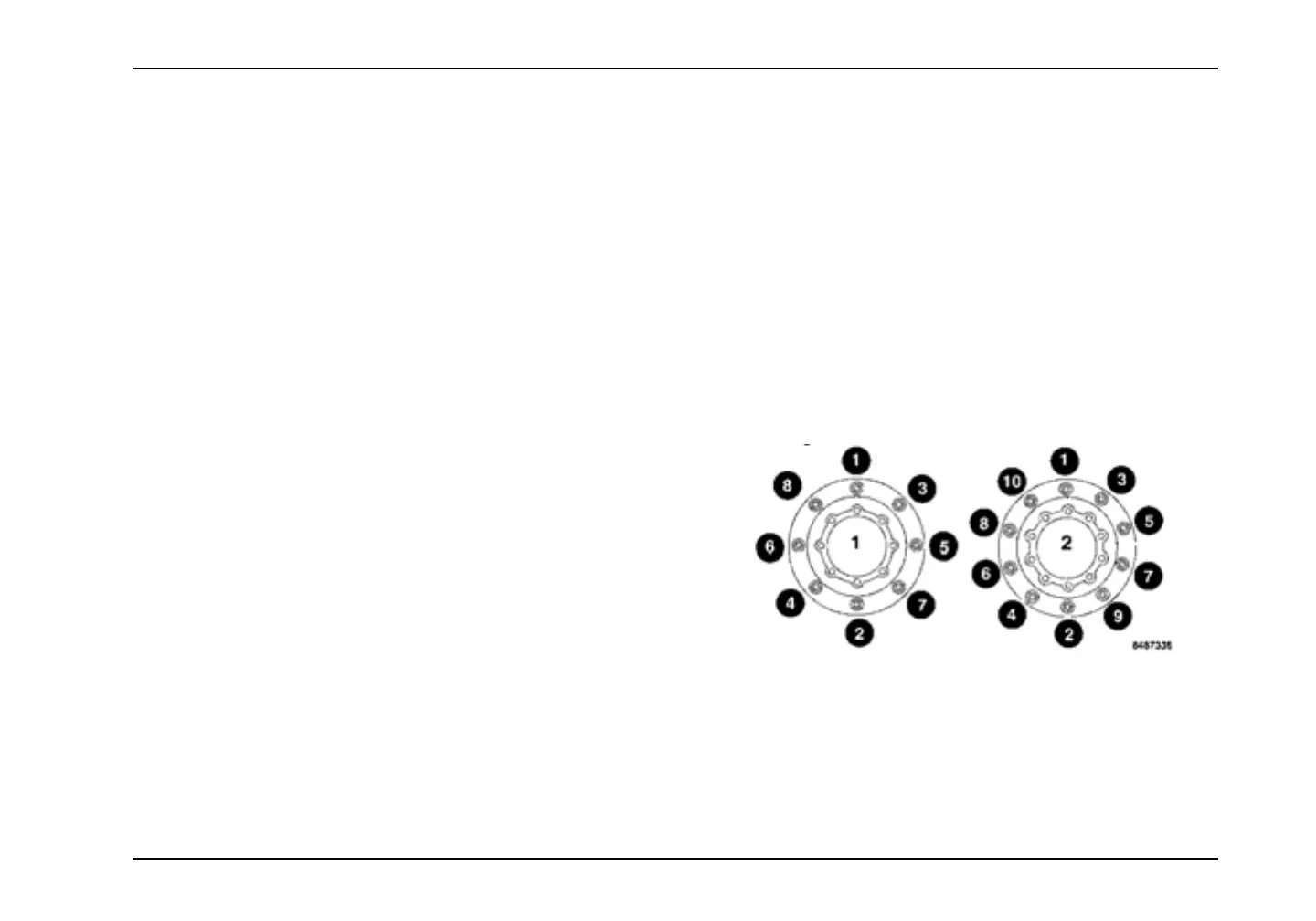

Tighteningprocedurefordiscwheelswithangenuts

(hub-piloted):

1.Cleanthematingsurfacesofthehub,drum,andwheel(s)

aswellasthewheelstudsandwheelnutswithawirebrush

priortoassembly.

2.Lubricatethetwo-piecewheelnutsbyputtingtwodropsofoil

intheslotbetweenthenutandwasher,andspinthewasher

tospreadtheoilaroundthenut-to-washercontactsurface.

3.Carefullylubricatethewheelstudthreadsbywipingthem

withafreshlyoiledcloth.Donotgettheoilonanyother

surfacesorthewheelclampingeffectivenesswillbe

reduced.

4.Topreventaluminumwheelsfromgettingstuckonthehub

duetocorrosion,applyathincoatofantiseizecompound

ordiscbrakecorrosioncontrolgreasetothehubpilotpads

only.

5.Slidetheinnerwheel(ifduals)orsteerwheeloverthewheel

studsandontothepilotpadsofthehub.Caremustbetaken

toavoiddamagetothestudthreadswhilepositioningthe

wheel.Ensurethatthewheelisrestingonthepilotpads

andisagainstthebrakedrum.

6.Hand-startallwheelnutstoavoidcrossthreading.

7.Startingwiththenutatthe12o’clockpositionandusing

theappropriatestarorcrisscrosspattern(seewheelnuts

torquesequencediagram),runthewheelnutsdownthe

wheelstudswithanimpactwrenchuntiltheyaresnug

againstthewheel.Thepurposeofthisstepistosnugthe

wheel(s)inthecorrectposition,nottoapplythenaltorque.

Thetighteningofeachnutshouldbestoppedimmediately

whenthewheeliscontacted,resultinginawheelnuttorque

wellbelowthenalspeciedtorque.

8.Useacalibratedtorquewrenchtoapplythespeciedtorque

toeachwheelnutinthesequencespeciedinthewheel

nutstorquesequencediagramabove.RefertoSECTION

8—MaintenanceIntervalsandSpecicationsforproper

torquevalues.

1.Flangenutmount–8stud

2.Flangenutmount–10stud

267

Loading...

Loading...