InspectionGuide

6.Tires:Checktreaddepthandtireination,andnoteif

treadisevenlyworn.Minimumtreaddepthis2/32inch

(2mm)onalldrivetires.Lookforcutsorotherdamage

tothetreadsidewalls.Seeifvalvecapsandstemsare

missing,broken,ordamaged.Checkdualspacingto

ensurethatdualwheelsareevenlyseparated,andthat

tiresarenottouchingoneanother.

7.Hub:Checkforobviousleakingonoutsideorinsideof

wheel.Inspectaxleangesandwheelsealsforleaks

andloosemountinghardwareorbrokenitems.

8.Springsuspension:Checkconditionofspringforcracks,

breaks,orshifting.Inspectspringhangerfasteners,

shackles,U-bolts,andnutsforwear,damage,and

tightness.

9.Slackadjuster:Checkslackadjusterandchamber

pushrodtravel.Whenpulledbyhand,pushrodshould

notmovemorethanapproximately1inch(25mm).

Anglebetweenpushrodandadjusterarmshouldbe

approximately90degreeswhenbrakesareapplied.

10.Airsuspension(ifequipped):Checkforairleaks,loose

components,anddamagetoairbag.Inspectrideheight

valveandlinkagefordamage.

NOTE:Checkairlinesandelectricalwiringforproper

security,damage,andchang.Listenforaudibleairleaks.

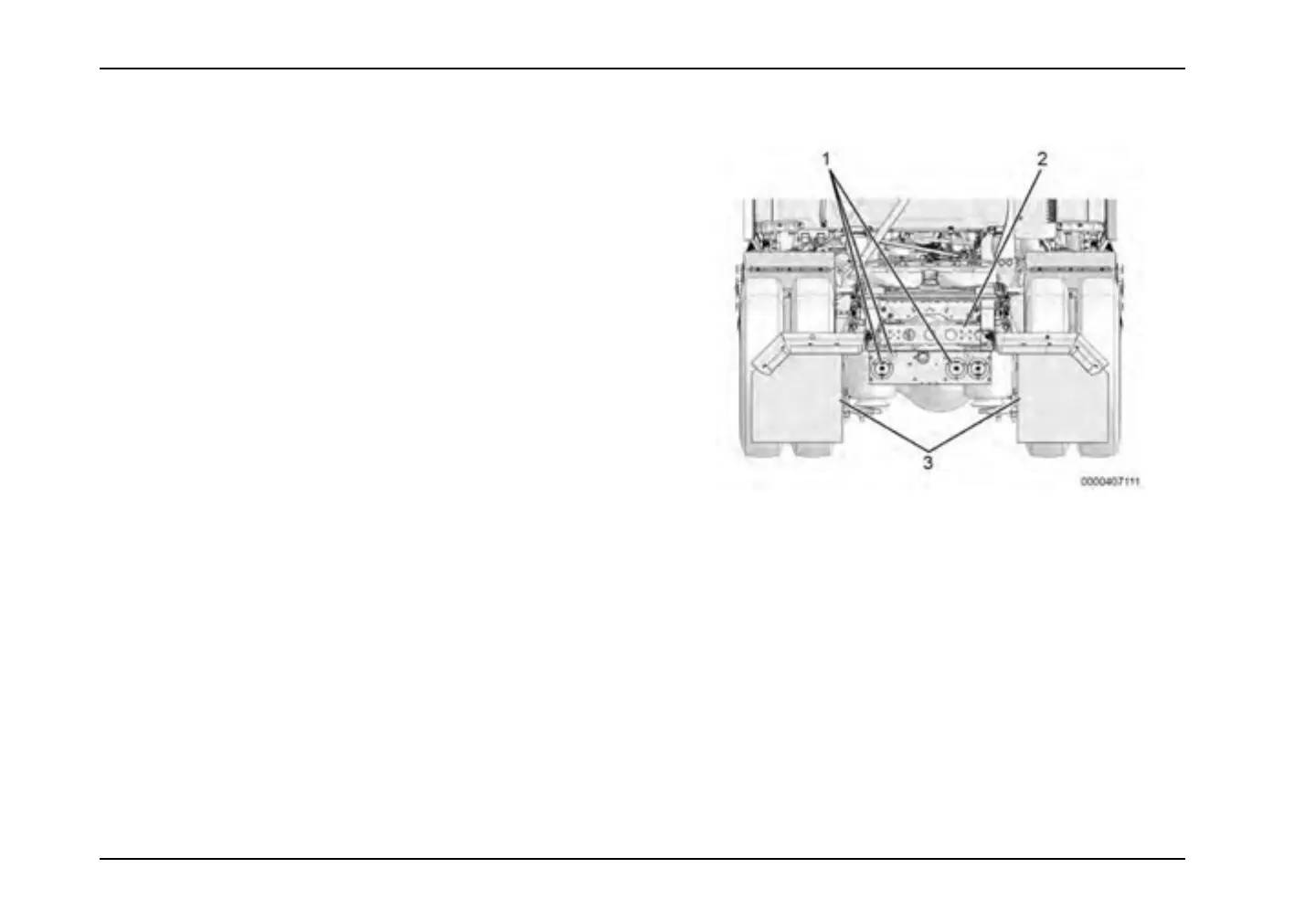

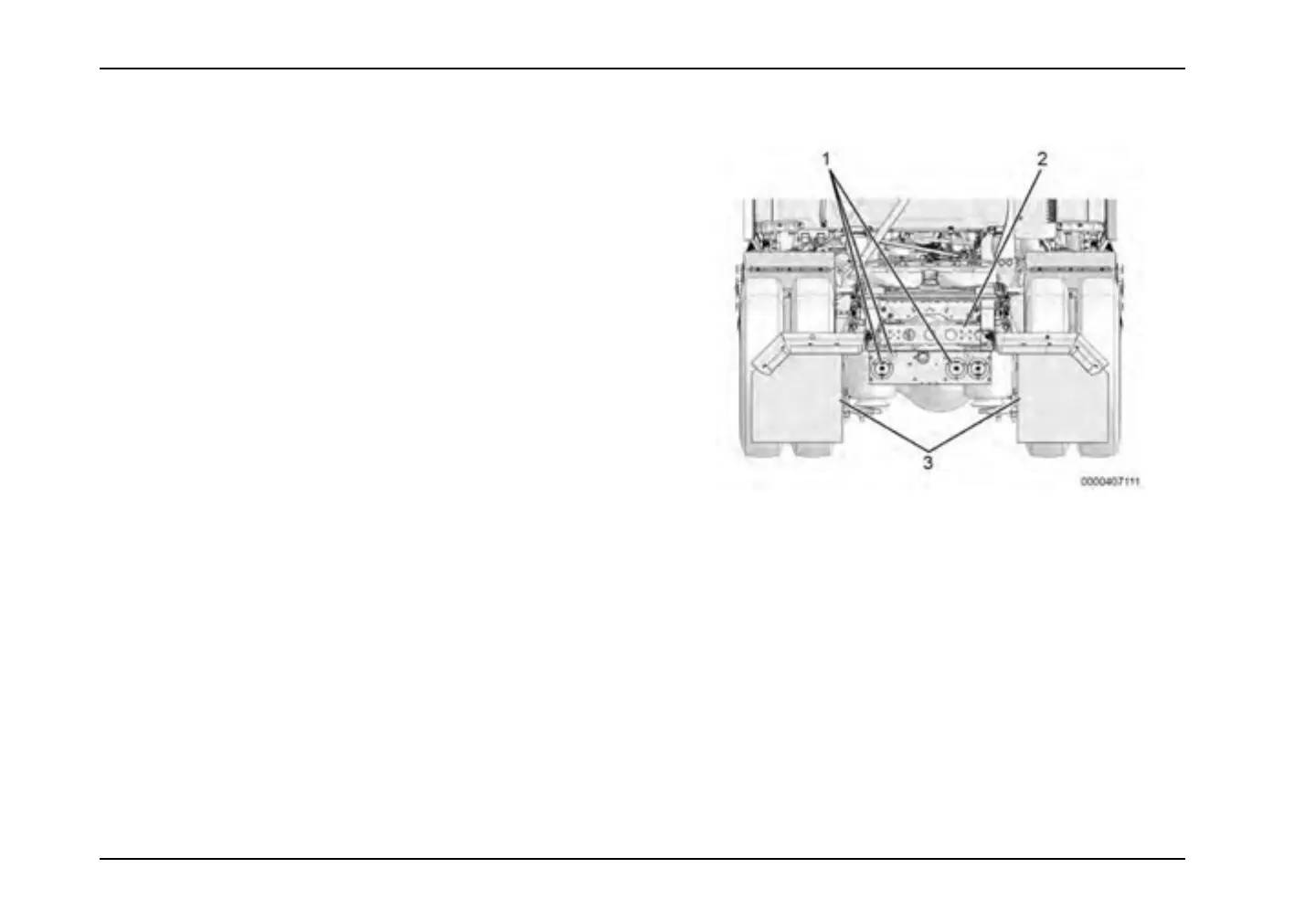

RearofTractor

1.Lightsandreectors:Checktoseethatreectorsand

lightsareclean.Makesurenonearemissingorbroken.

Rearrunninglightsshouldbeclean,notbrokenand

REDincolor.

2.Frame:Checkforcracksorbendsinframe.Makesure

therearenoloose,cracked,bent,broken,ormissing

crossmembersorcrossmemberfasteners.

3.Mudaps:Inspectrearmudapsandmountingsfor

damageandpropersecurity.

NOTE:Checkairlinesandelectricalwiringforproper

security,damage,andchang.Listenforaudibleairleaks.

38

Loading...

Loading...