Section13PROPULSION

Subsection 02 (DRIVE SYSTEM)

Install the large washer no. 28 and nuts no. 21.

Slightly tighten nuts but keep loose so that the as-

sembly still can move and self adjust when insert-

ing the alignment shaft further in this procedure.

NOTE: Completely tightening nuts would make

the alignment more difficult.

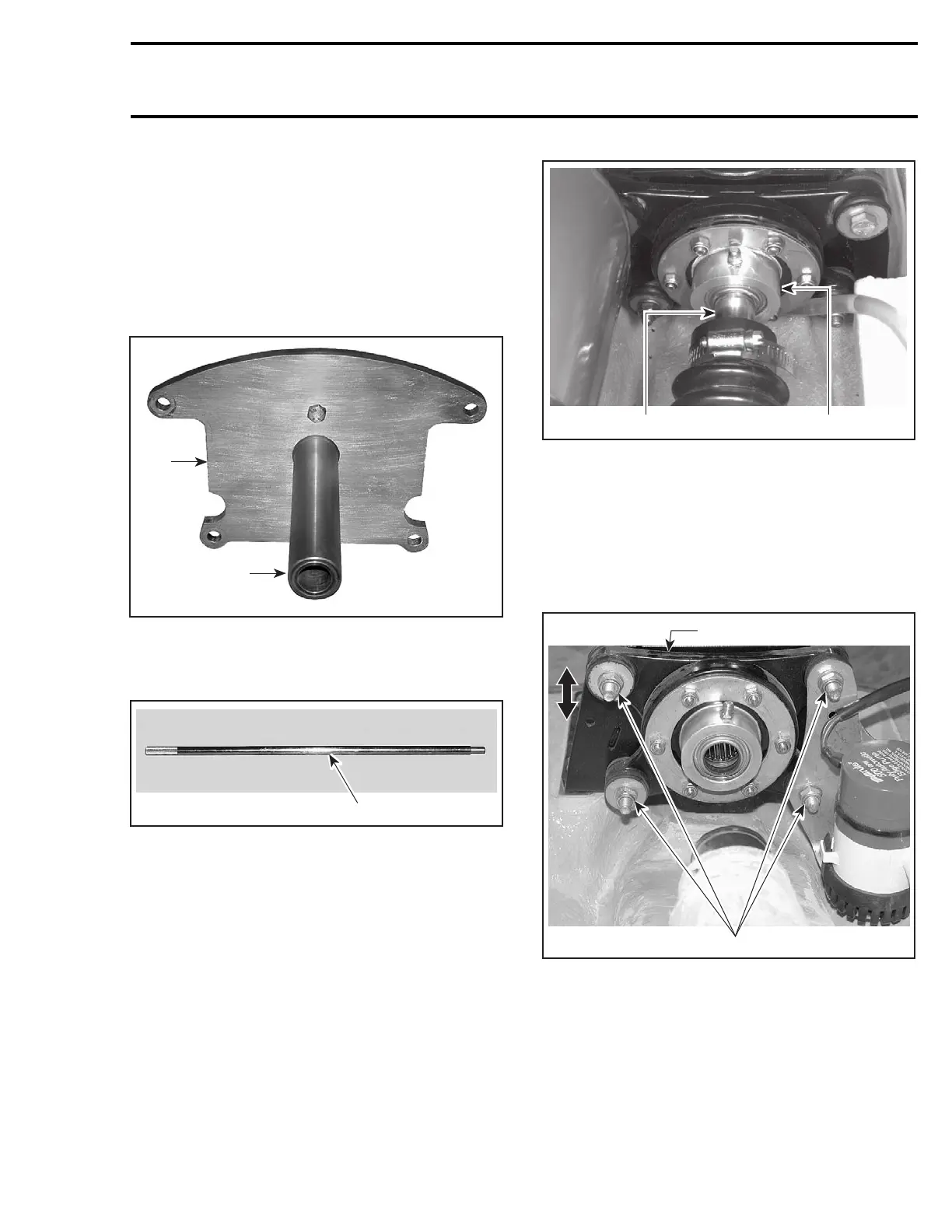

Align the seal carrier using the following tools:

– support plate kit (P/N 529 035 570)

F19J09A

1

2

1. Plate (P/N 529 035 507)

2. Support (P/N 529 035 511)

– alignment shaft (P/N 295 000 141).

F00B0GA

1

1. Alignment shaft

Install support plate at rear of watercraft.

Carefully slide shaft through seal carrier and shaft

support. Ensure that shaft goes farther than shaft

support.

F05I08A

1 2

TYPICAL

1. Alignment tool

2. Seal carrier

If alignment tool does not slide easily through seal

carrier, perform the alignment as follows.

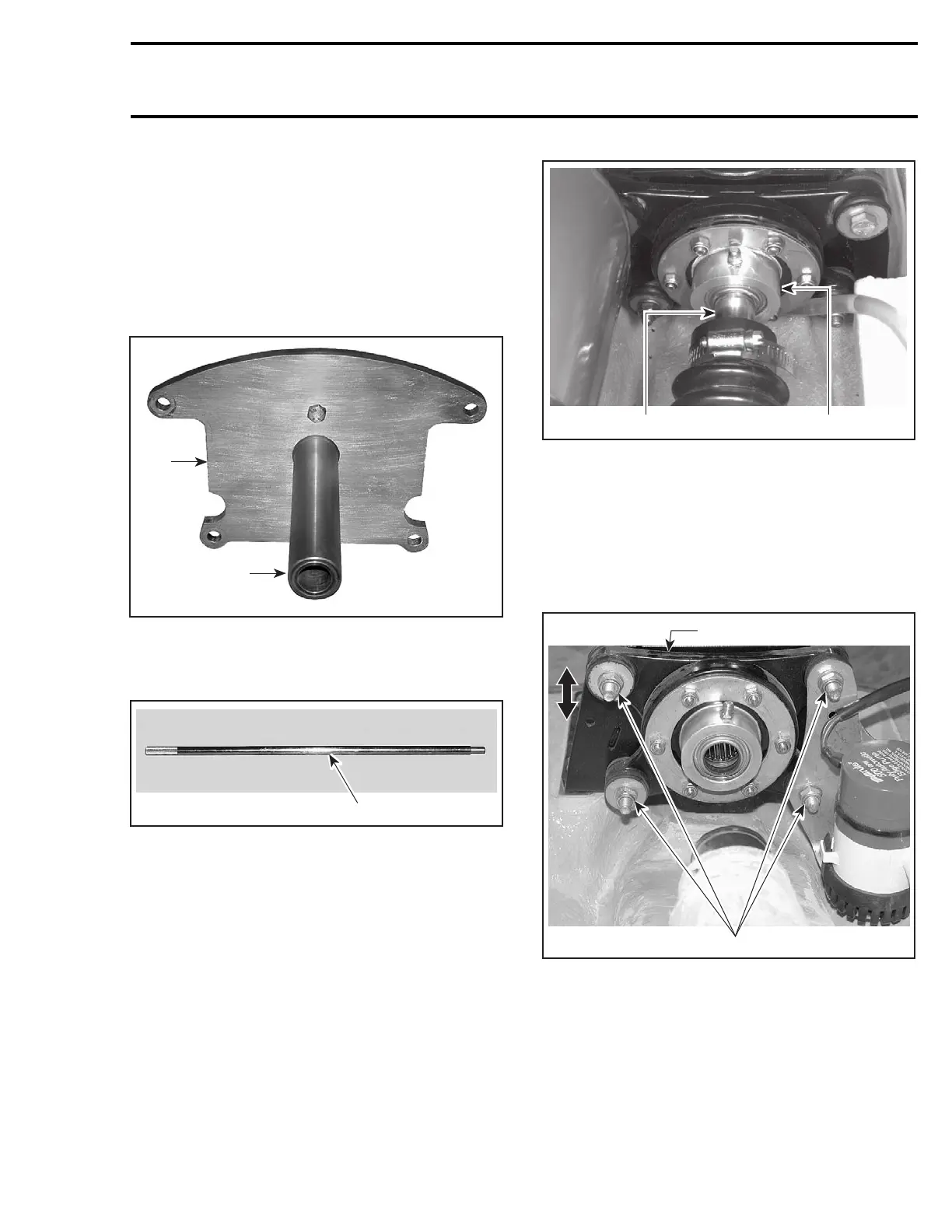

For vertical alignment, loosen damping support

nuts no. 30 andmovethesupportno. 29 up and

down as necessary.

F00B25A

2

1

1. Damping support

2. Loosen nuts

When done, ensure to apply Loctite 243 on screw

threadsthentorquescrewsto22N•m(16lbf•ft)

in a criss-cross sequence.

For horizontal alignment, loosen shaft support

screws no. 32 and move the support no. 31

sideways as necessary.

smr2004-Complete Line Up 667

Loading...

Loading...