INJECTION NEEDLE

. . . .. . . ... .... .... .... ..... ..

Sievers TOC-R3 Operation and Maintenance Manual

DLM 95000-01 EN Rev. A 204 © Veolia 2023

11. Reinstall the Injection Needle and Furnace Head Assembly unit back on top of the

Furnace.

• Lower the Injection Needle [15] slightly into the Furnace Head Cover [6] and then

tighten the red Furnace Head Compression Fitting [10A].

• Insert the Furnace Head Assembly (with attached Injection Needle) into the

central hole inside the Furnace.

• Rotate the Furnace Head Z-Brackets to clamp down on the Furnace Head

Assembly and tighten the three Thumb Screws to be finger-tight. Important!

Ensure that the metal Furnace Head Z-Brackets only touch the High Temperature

Gasket [7]! If needed, slide the slotted Furnace Head Z-Brackets farther away

from the center fitting before tightening the Thumb Screws.

12. Carefully tilt the Furnace back into its vertical, upright position.

13. Secure it in place using the Wing Screw that was removed earlier.

14. While holding the Injection Needle [15] in one hand, carefully loosen the Compression

Nut [10A] with the other. Important! Do not let go of the Injection Needle! It will fall

into Furnace Cartridge!

15. Carefully slide the Injection Needle [15] up and insert it into the Injection Block port.

Ensure that the Ferrule [14B] seats into the Injection Block and then tighten the

Injection Block Compression Fitting [14A] over the Ferrule [14B] to be finger-tight.

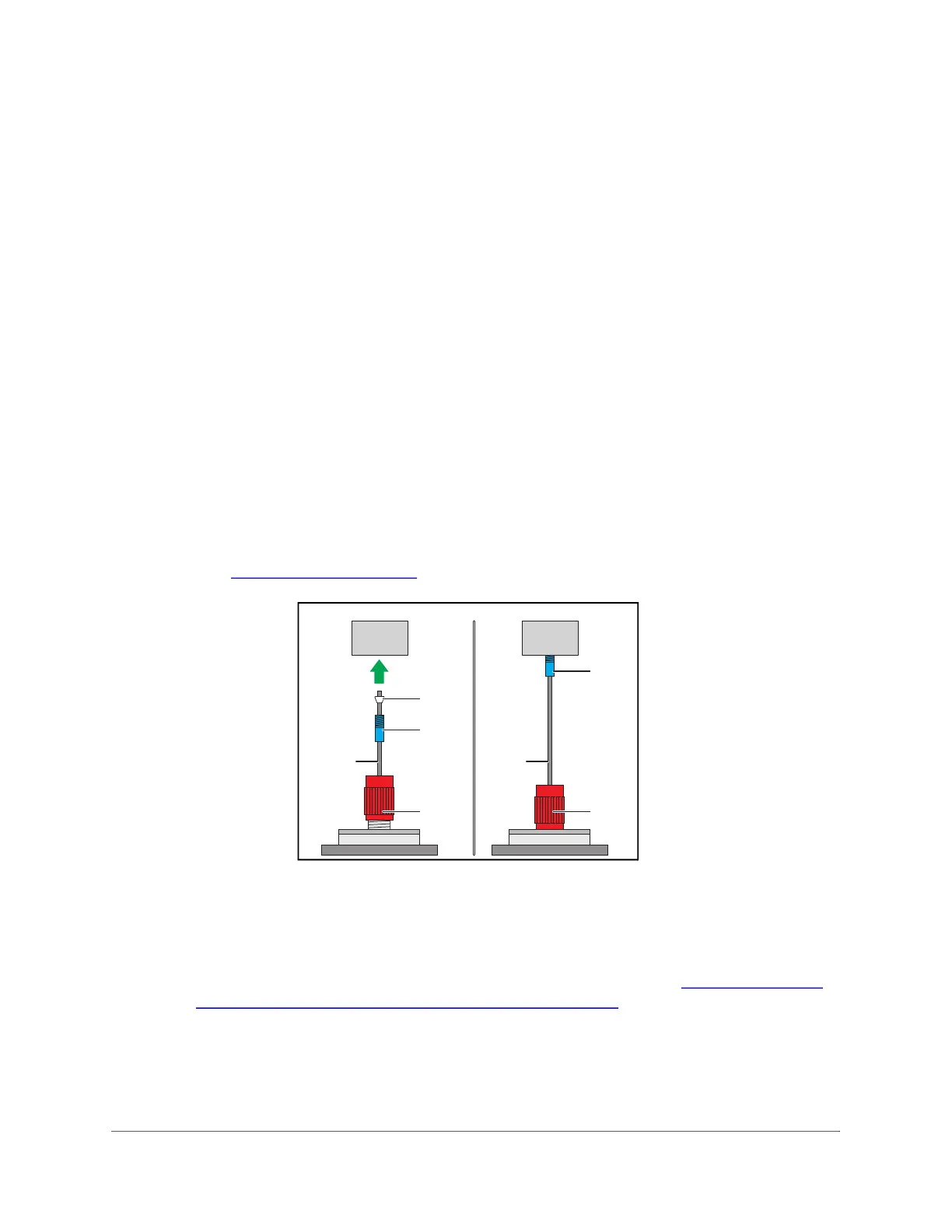

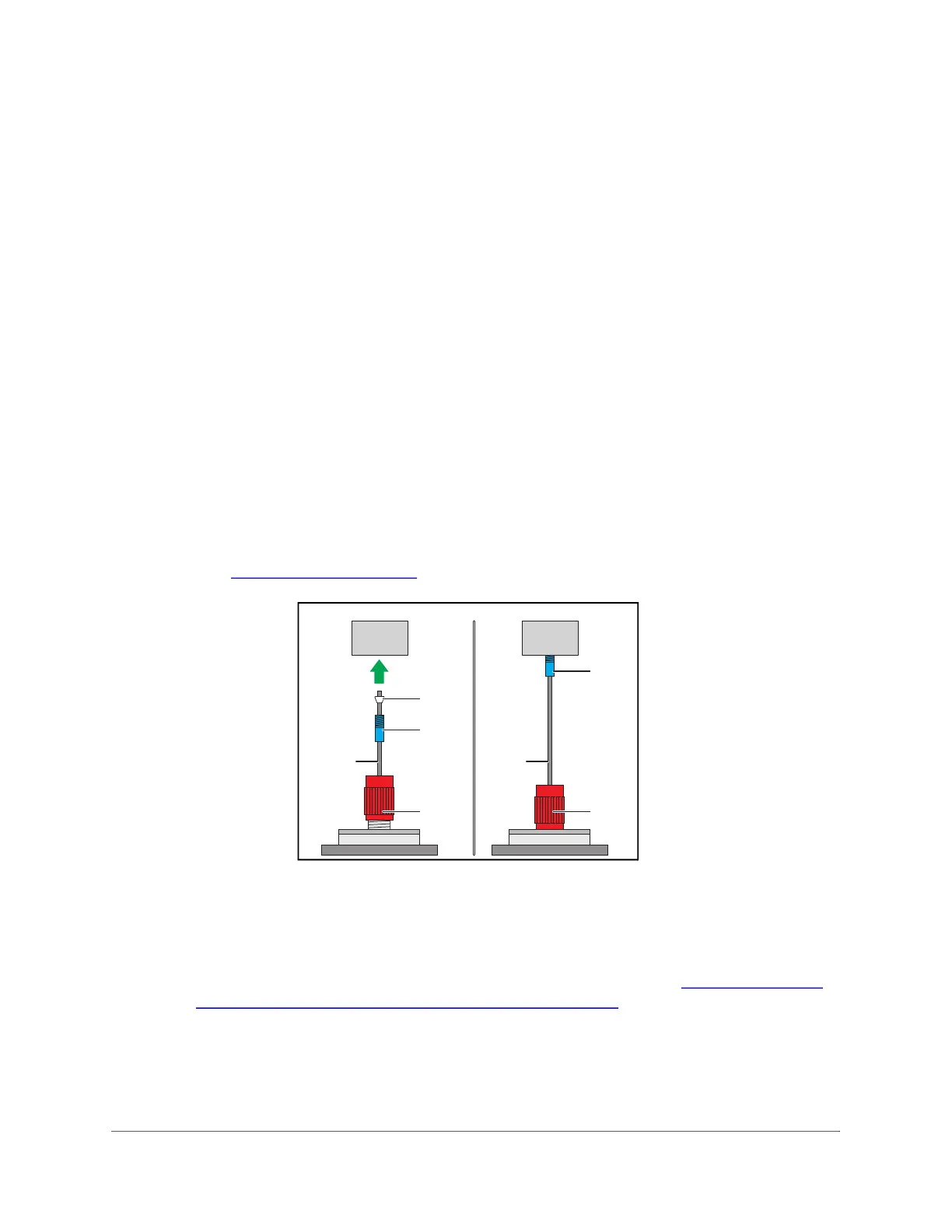

See Figure 6-11 on page 204

.

Figure 6-11: Connect Injection Needle to Injection Block

16. Next, re-tighten the Compression Nut [10A] to be finger-tight to secure the Injection

Needle in place.

17. Navigate to the Menu → Service → Sensors screen. Check the “Carrier Gas Flow

In” Sensor reading for adequate flow. For more information, see “Important Sensor

Values — Analyzer On, Analysis Stopped” on page 196.

18. If planning to perform more maintenance, follow the procedures listed in the

appropriate sections of this chapter. Otherwise, you may turn the Furnace Power

back “On” and close the Analyzer door. The Analyzer will require at least two hours to

reach operating temperature.

[15]

[14A]

[14B]

[10A]

[15]

[14A]

[10A]

Loading...

Loading...