MAINTENANCE

Chapter 6

............

Sievers TOC-R3 Operation and Maintenance Manual

DLM 95000-01 EN Rev. A 213 © Veolia 2023

contaminants. Ensure the section of tubing is longer than the Transfer Tube so it

does not get stuck.

NOTE: The Transfer Tube may be slightly discolored from normal use. This is

expected.

7. Put the Furnace Foot Assembly back together. Insert the small Ceramic Disk into the

center of the Furnace Foot Assembly. Ensure the Disk is laying flat inside the Furnace

Foot Assembly. Important! Failure to install this correctly will result in hardware

failure!

8. Reinstall the Furnace Foot Assembly on to the Furnace Sleeve extending below the

Furnace.

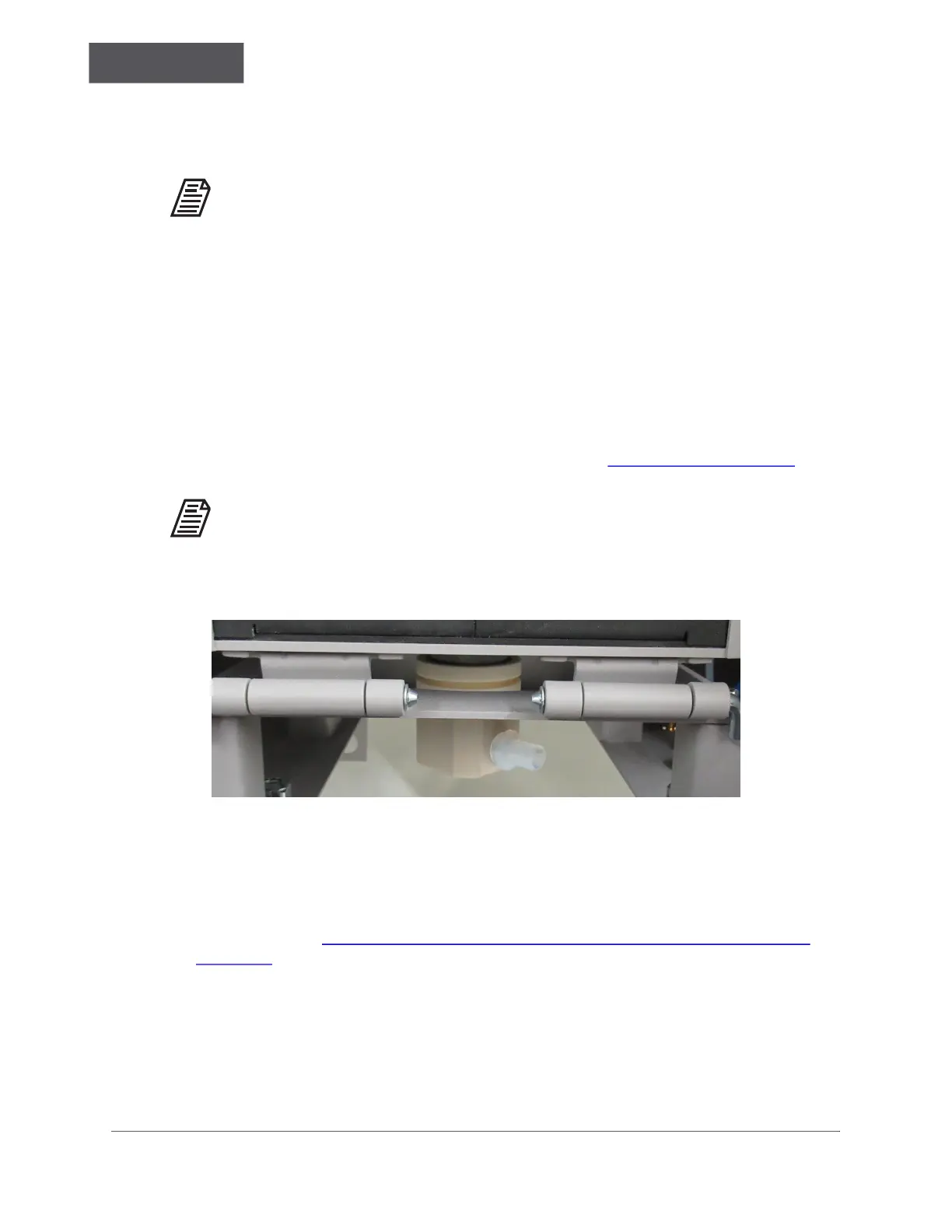

• Working from below through the Furnace Access Port, gently push the Furnace

Foot Assembly on to the bottom of the Furnace Sleeve extending out from below

the Furnace. Ensure the Transfer Tube Port is oriented at a 45° angle between the

Gas Cooler Unit and the front of the Analyzer. See Figure 6-15 on page 213

.

NOTE: If the desired angle is not achieved on first attempt, rotate the Furnace

Foot Assembly [12] anticlockwise until the desired position is obtained. Do

not rotate clockwise or it will loosen the fittings inside the Furnace Foot

Assembly [12] and risk hardware failure!

Figure 6-15: Furnace Foot Assembly correct orientation

9. Reconnect the Transfer Tube to the Furnace Foot Assembly and the Gas Cooler Unit.

Ensure both connections are tight.

10. Navigate to the Menu → Service → Sensors screen. Check the “Carrier Gas Flow

In” and the “Carrier Gas Flow Out” Sensor readings for adequate flow. For more

information, see “Important Sensor Values — Analyzer On, Analysis Stopped” on

page 196.

11. Reinstall the Furnace Access Cover.

12. If planning to perform more maintenance, follow the procedures listed in the

appropriate sections of this chapter. Otherwise, you may turn the Furnace Power

back “On” and close the Analyzer door. The Analyzer will require at least two hours to

reach operating temperature.

Loading...

Loading...