SYSTEM DESCRIPTION

Chapter 2

............

Sievers TOC-R3 Operation and Maintenance Manual

DLM 95000-01 EN Rev. A 45 © Veolia 2023

physical properties of the sample and organic species present in solution. Calibration and

Method parameters may need to be adjusted depending on the application.

The "raw" PID Detector signals are displayed as “POC/VOC in ppm” and the measured

concentrations of POC/VOC are displayed in “mg/L”.

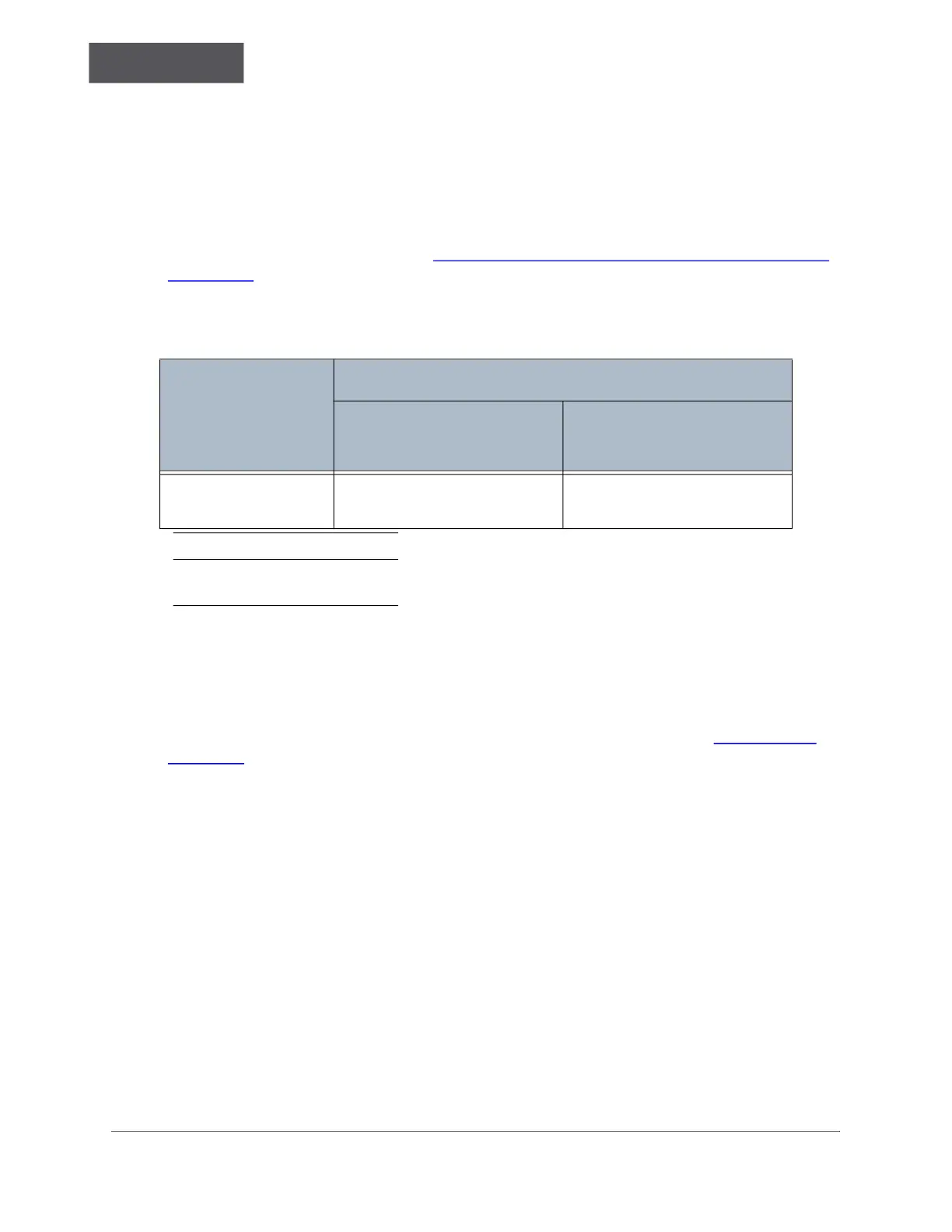

To verify your PID Detector variation, go to the Menu → General → Machine

Configuration screen and refer to Table 2-3, “Typical PID Detector Measuring Range,”

on page 45.

Sensors

The Analyzer contains the following Sensors. These Sensors provide real-time feedback

about different Analyzer system components. For more information, see “Sensors” on

page 134.

• BF1 (Carrier Gas Flow In Sensor) — Displays the current “Carrier Gas Flow In” to

the Analyzer.

• BF2 (Carrier Gas Flow Out Sensor) — Displays the current “Carrier Gas Flow

Out” of the Analyzer.

• BP1 (Pressure Reactor Sensor) — Displays the current pressure at the nozzle of

the Furnace (shown as “Reactor”) (EB1).

• BP2 (Pressure Nozzle Sensor) — Displays the current pressure at the nozzle of

the Injection Accumulator (CM1).

CM1 — Injection Accumulator

The CM1 (Injection Accumulator) is a pressure vessel that stores a large volume of

Carrier Gas used to inject sample into the Furnace. The CM1 uses the system inlet

regulated pressure (the “Carrier Gas Flow In” pressure setting). The “Carrier Gas Flow In”

setting should never exceed 35 l/h.

Table 2-3: Typical PID Detector Measuring Range

Purchased

Optional Detector

PID Detector Range

POC/VOC

a

[ppm]

(Firmware Label)

b

a. PID Gas Concentration Range.

b. “PID Range” value is found on the Menu → General → Machine Configuration

Screen.

POC/VOC

c

[mg/L]

(Analytical Range)

c. Liquid Sample Concentration Range.

Up to 25 mg/L as

POC/VOC

2000 Up to 25

Loading...

Loading...