No. Parameter Name No. Parameter Name

b6-02 Dwell Time at Start H2-01 Terminals MA, MB, and MC Function Selection

C1-01 Acceleration Time 1 L1-01 Motor Overload Protection Selection

C1-02 Deceleration Time 1 L4-01 Speed Agreement Detection Level

C6-02 Carrier Frequency Selection L6-02 Torque Detection Level 1

d1-01 Frequency Reference 1 L6-03 Torque Detection Time 1

Note: Read the instructions listed in Hoist Application Preset Specifics on page 73 when using Hoist Application Preset.

Table 4.17 Crane Application (Travel): Parameters and Settings

No. Parameter Name Optimum Setting

A1-02 Control Mode 0: V/f control

b1-01 Frequency Reference Selection 0: Operator

C1-01 Acceleration Time 1 3.0 s

C1-02 Deceleration Time 1 3.0 s

C6-01 Duty Cycle 0: Heavy Duty

C6-02 Carrier Frequency Selection 2: 5 kHz

d1-01 Frequency Reference 1 6.0 Hz

d1-02 Frequency Reference 2 30.0 Hz

d1-03 Frequency Reference 3 60.0 Hz

H1-05 Multi-Function Digital Input Terminal S5 Function 3: Multi-Step Speed 1

H1-06 Multi-Function Digital Input Terminal S6 Function 4: Multi-Step Speed 2

H2-02 Terminals P1 Function Selection (open-collector) 37: During frequency output

L3-04 Stall Prevention Selection during Decel 0: Disabled

L8-05 Input Phase Loss Protection Selection 1: Enabled

L8-07 Output Phase Loss Protection 1: Triggered when a single phase is lost

L8-38 Carrier Frequency Reduction 1: Always derated

L8-41 Current Alarm Selection 1: Enabled (alarm output)

Table 4.18 Parameters Automatically Saved as Preferred (A2-01 to A2-16)

No. Parameter Name No. Parameter Name

b1-01 Frequency Reference Selection d1-03 Frequency Reference 3

C1-01 Acceleration Time 1 E2-01 Motor Rated Current

C1-02 Deceleration Time 1 H1-05 Multi-Function Digital Input Terminal S5 Function

C6-02 Carrier Frequency Selection H1-06 Multi-Function Digital Input Terminal S6 Function

d1-01 Frequency Reference 1 H2-01 Terminals MA, MB, and MC Function Selection

d1-02 Frequency Reference 2 L1-01 Motor Overload Protection Selection

Note: A sequence to release the brake is needed when the multi-function output photocoupler P2-PC closes. Refer to Hoist Application Preset Specifics on page 73 for more

information.

n

Hoist Application Preset Specifics

This section lists some important points when using the Hoist Application Preset (A1-06 = 6).

Conditions for Opening and Closing the Holding Brake

Use an output signal as described below to operate the holding brake in a hoist application.

Make sure that frequency detection is set so that it does not operate during baseblock (L4-07 = “0”). Even when an external baseblock command is present,

the output frequency will rise when a run command is entered. If frequency detection were to be enabled during baseblock, (i.e., L4-07 = 1) then the brake

would be improperly released. To activate and release the brake using the multi-function output terminals P2-PC, program the drive as shown in the table

below:

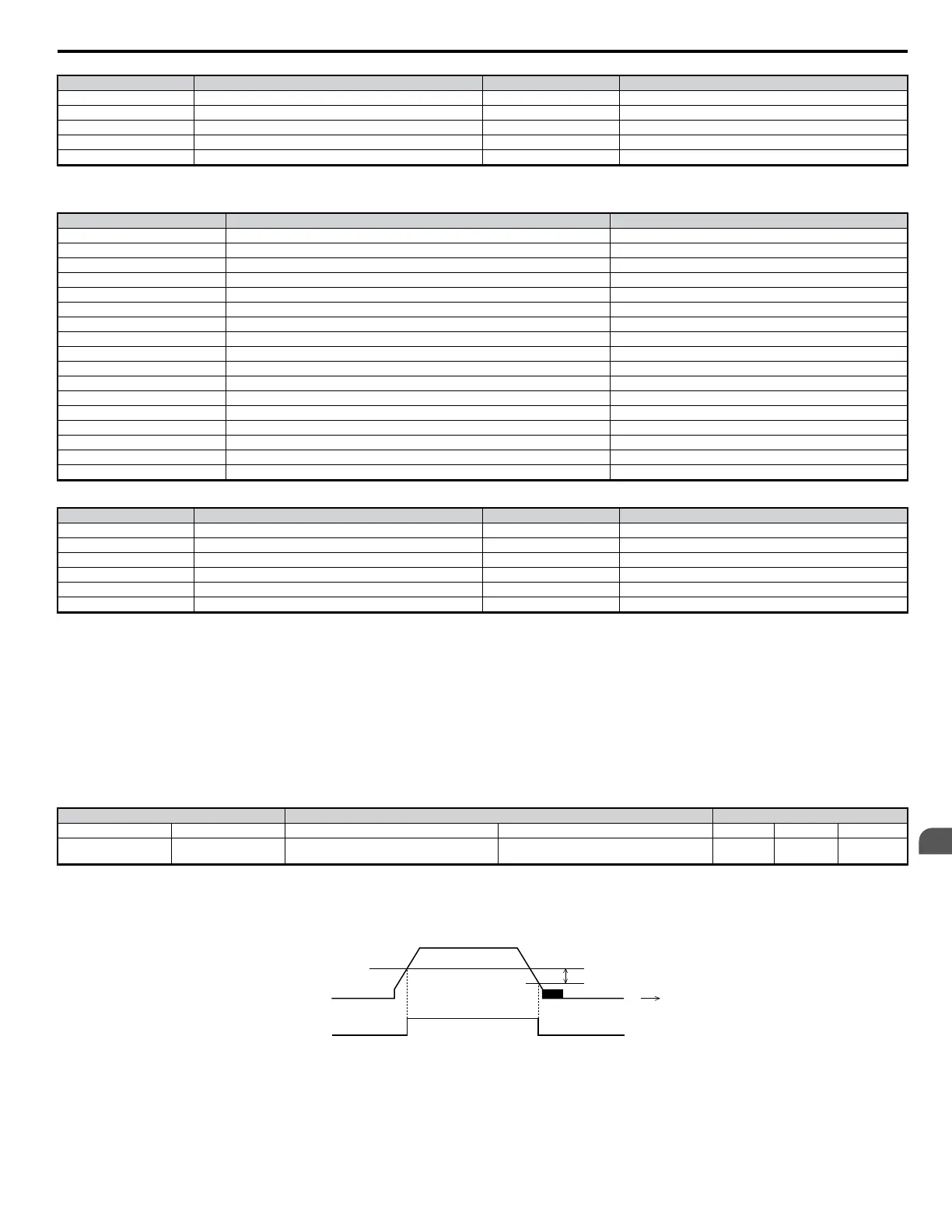

Brake Open/Close Brake Activation Level Control Mode

Function Parameter Signal Parameter V/f OLV OLV for PM

Frequency Detection 2

L4-07 = 0

H2-03 = 5

Frequency Detection Level Frequency Detection

Width

L4-01 = 1.0 to 3.0 Hz <1>

L4-02 = 0.0 to 0.5 Hz <2>

O O -

<1> This setting range is available when using OLV Control. In V/f Control, set the level as the motor rated slip frequency pulse 0.5 Hz. Not enough motor torque will be created if this value is

set too low, and the load may tend to slip. Make sure this value greater than the minimum output frequency and greater than the value of L4-02 as shown in the diagram below. If this value

is set too high, there may be a jolt at start.

<2> Adjust Hysteresis for Frequency Detection 2 by changing the frequency detection width (L4-02) between 0.0 and 0.5 Hz. If the load slips during stop, make incremental changes of 0.1 Hz

until the load no longer slips.

L4-02

L4-01

OFF

ON

Output

Frequency

Frequency

Detection 2

Time

Sequence Circuit Design for Opening and Closing the Holding Brake

Design the braking sequence as follows:

The brake should release when terminal P2-PC closes in response to the run conditions on the sequence side.

When a fault signal is output, the brake should close. When an up or down command is entered, the brake should release.

4.5 Application Presets

YASKAWA ELECTRIC SIEP C710606 18A YASKAWA AC Drive – V1000 Technical Manual (Preliminary)

73

4

Start-Up Programming

& Operation

Loading...

Loading...