12.5.17 0x6067/0 Position window

0xFFFF FFFF

• Motion Control:

• Non motion Control (conf. ≠ x40)

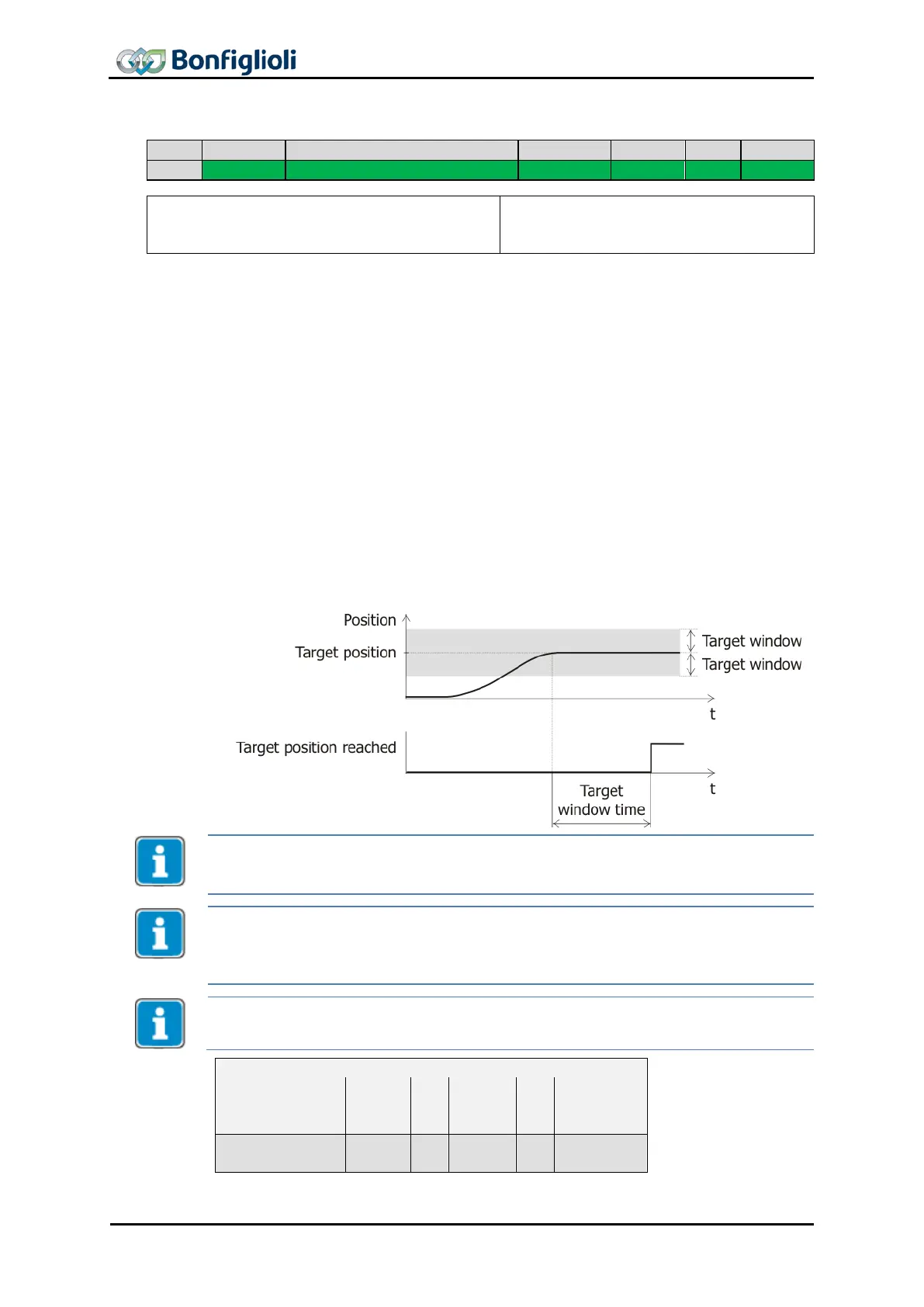

The signal “target position reached” can be changed in accuracy with Object 0x6067

position window

for the modes which use Status Word Bit 10 “Target reached” as

“Target Position reached” like “Profile Positioning Mode” and “Table Travel Record

Mode”.

Object 0x6067

position window

defines a symmetrical range of accepted positions

relative to the target position in user units. If the actual value of the position mea

s-

urement device is within the position window, the target position is regarded as

reached. “Target reached” is displayed in Bit 10 of the status word. The actual pos

tion must be inside the position window during the time specified in Object

position window time

.

If the actual position drifts outside the target window or if a new target position is set,

the “Target reached” Bit is reset until the position and time conditions are met again.

The valid value range of object 0x6067/0

position window

is 0 … 0x7FFF FFFF (2

31

-

Writing a value of 0x8000 0000 (2

31

)… 0xFFFF FFFE (2

32

-

2) results in an SDO abort

(value range).

If the value of

position window

is set to 0xFFFF FFFF (2

32

-1) OR 0, the position wi

n-

dow control is switched off.

Writing to object

position window

automatically generates a write command to parame-

ter Target Window 1165 (data set 5, all data sets in RAM only !).

If object 0x6067/0 was written and then a save parameters command (object 0x1010)

processed, the object value is stored in non volatile memory.

After the next power on of the inverter, the previously set value is reactivated and

overwrites the setting of Target Window 1165.

The dimension of the user units is defined by 0x6091

Gear ratio

and 0x6092

Feed con-

stant

.

CB: Control byte SI: Sub Index All values in hexadecimal without leading 0x

128 CM-CAN ACU 04/13

Loading...

Loading...