NOTE

The values are entered automatically into the EEPROM on the controller. If values

are to be written cyclically, there must be no entry into the EEPROM, as it only has a

limited number of admissible writing cycles (about 1 million cycles). If the number of

admissible writing cycles is exceeded, the EEPROM is destroyed.

To avoid this, cyclically written data can be entered exclusively into the RAM without a

writing cyc

le taking place on the EEPROM. The data are volatile, i.e., they are lost on

power-off and have to be written again after power-on.

12.3.2.1 Example Writing an index parameter

Typically an index parameter is written during commissioning or regularly at simple

positioning applications.

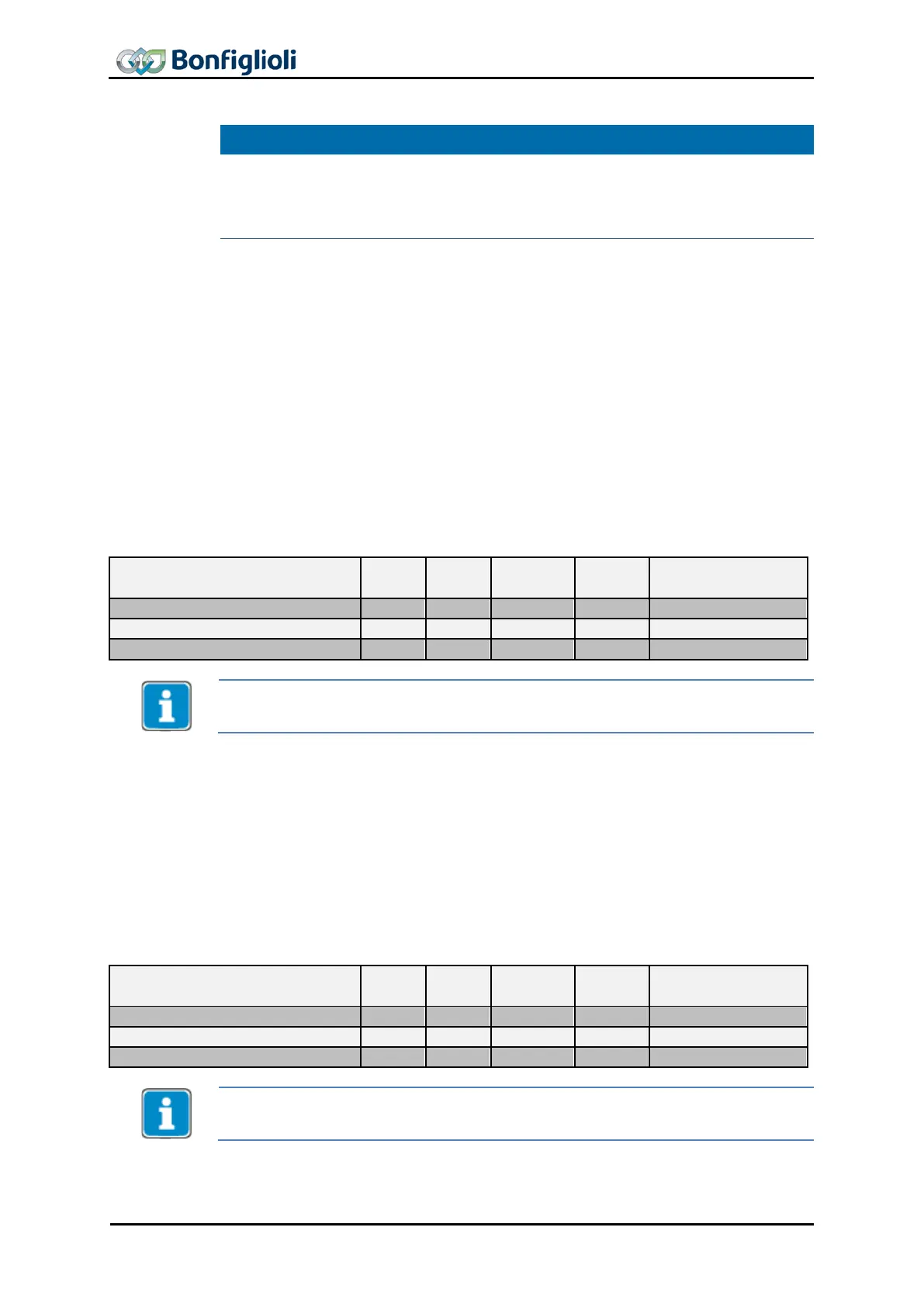

Writing Parameter 1202 Target Position / Distance (Typ long), in Index 1 into RAM

(index 34 for write access) with Parameter value 30000.

Index = 1200 + 0x2000 = 0x24B0, Value (int) = 34 = 0x0022

Index = 1202 + 0x2000 = 0x24B2, Value (long) = 30000 = 0x0000 7530

Write Request P. 1200 to Index 34

Write Request P. 1202 to 30000 u

If several parameter of an index should be changed, it is sufficient to set the index

access parameter 1200 once at the beginning.

12.3.2.2 Example Reading an index parameter

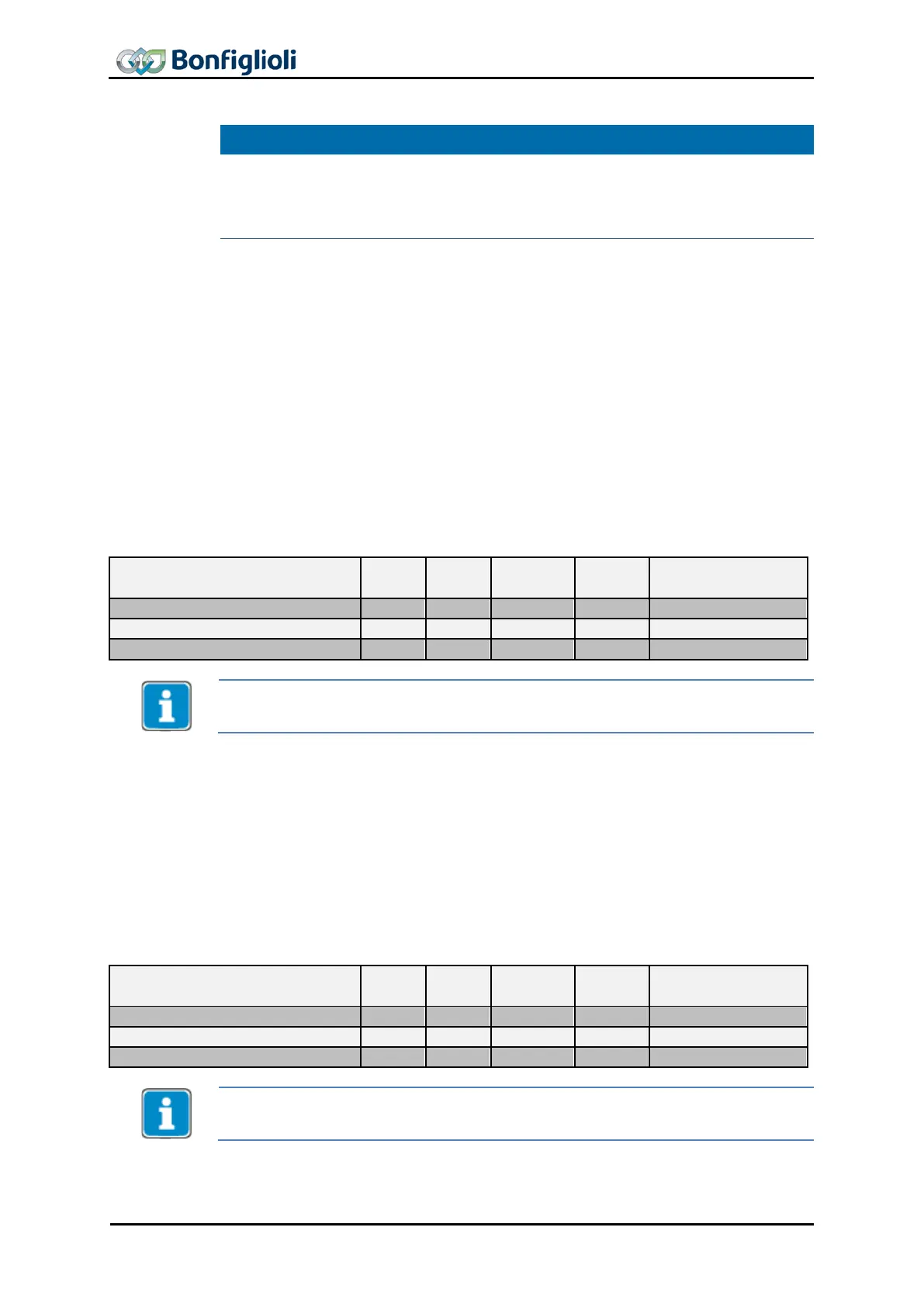

To read an index parameter, first the index access parameter has to be set to the

corresponding index. After that, the parameter can be read out.

Reading Parameter 1202 Target Position / Distance (Typ long), in Index 1 with Pa-

rameter value 123000.

Index = 1201 + 0x2000 = 0x24B1, Value (int) = 1 = 0x0001

Index = 1202 + 0x2000 = 0x24B2, Value (long) = 123000 = 0x0001 E078

Write Request P. 1201 to Index 1

If several parameter of an index should be read, it is sufficient to set the index access

parameter 1201 once at the beginning.

84 CM-CAN ACU 04/13

Loading...

Loading...