8.2 Setting of the capacity / flow rate

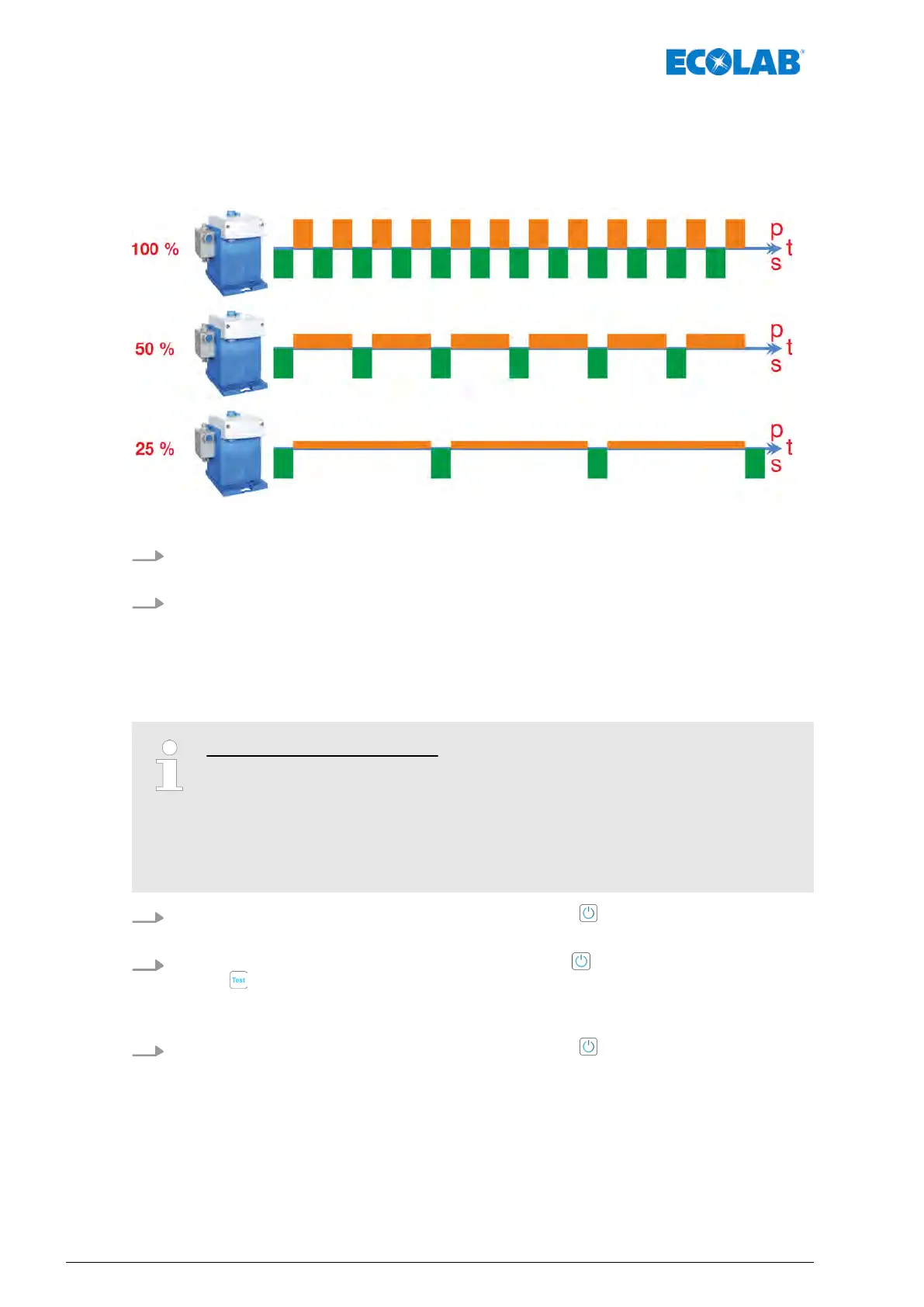

The stepper motor technology means that both the suction stroke duration and metering

stroke duration can be set separately during operation via the stroke adjustment

(Fig. 18

, pos. 1).

Fig. 19: Time distribution (t) of the suction (s) and metering stroke (p) at a metering rate setting of 100, 50 and 25%

1. Use the‘rotary button for stroke adjustment’ (Fig. 18, 1) to set the required capacity /

flow rate.

2. Locking mechanism to fix the rotary button in place (

Fig. 18, 2) should be tightened

using a suitable screwdriver to exclude the risk of accidental adjustment.

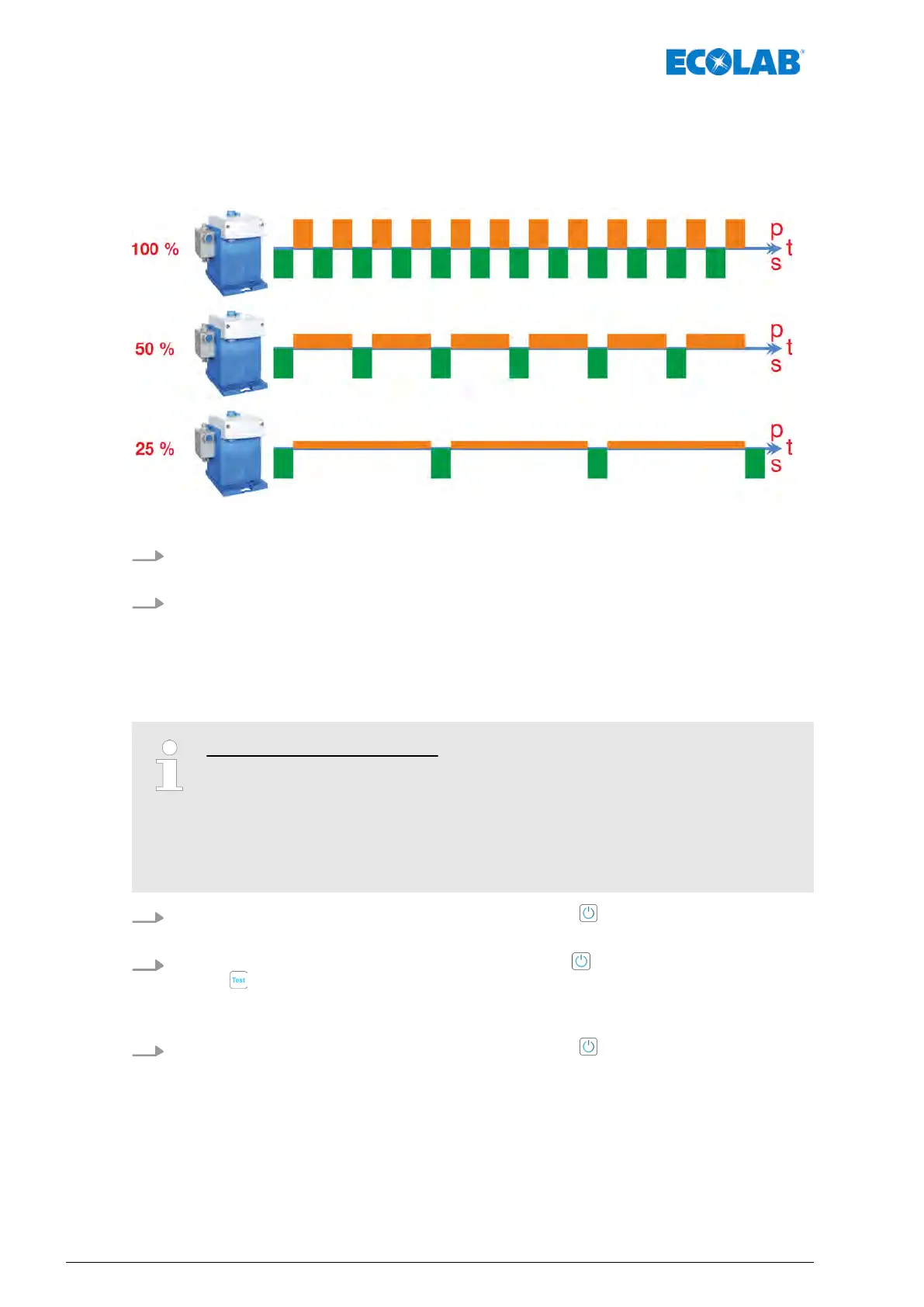

8.3 Setting / changeover of the viscosity

Meaning of the LED colours:

– LED - Metering mode "low" (left): Fig. 18, 4.

– Permanently on when the pump is started, colour: green (standby).

– Flashing when operated in "low" metering mode, colour: yellow

.

– LED - Metering mode "high" (right): Fig. 18, 5.

– Flashing when operated in "high" metering mode, colour: yellow.

1.

Switch of

f the pump by pressing the ‘ON/OFF button’

(Fig. 18, 6).

ð

The pump stops operating, and all the LEDs go out.

2.

Reset the viscosity by pressing the ‘ON/OFF button’ (Fig. 18, 6) and the ‘T

est

button’

(Fig. 18, 7) simultaneously for approximately 3 seconds.

ð

The associated LED (low = left

Fig. 18, 4, high = right, Fig. 18, 5) flashes green

briefly.

3.

Switch of

f the pump by pressing the ‘ON/OFF button’

(Fig. 18, 6).

ð

The pump starts and the LED for the newly set viscosity flashes.

Operation

50417102264 Rev. 5-01.2019

Loading...

Loading...