ESAB Cutting Systems

CROSSBOW Page 138

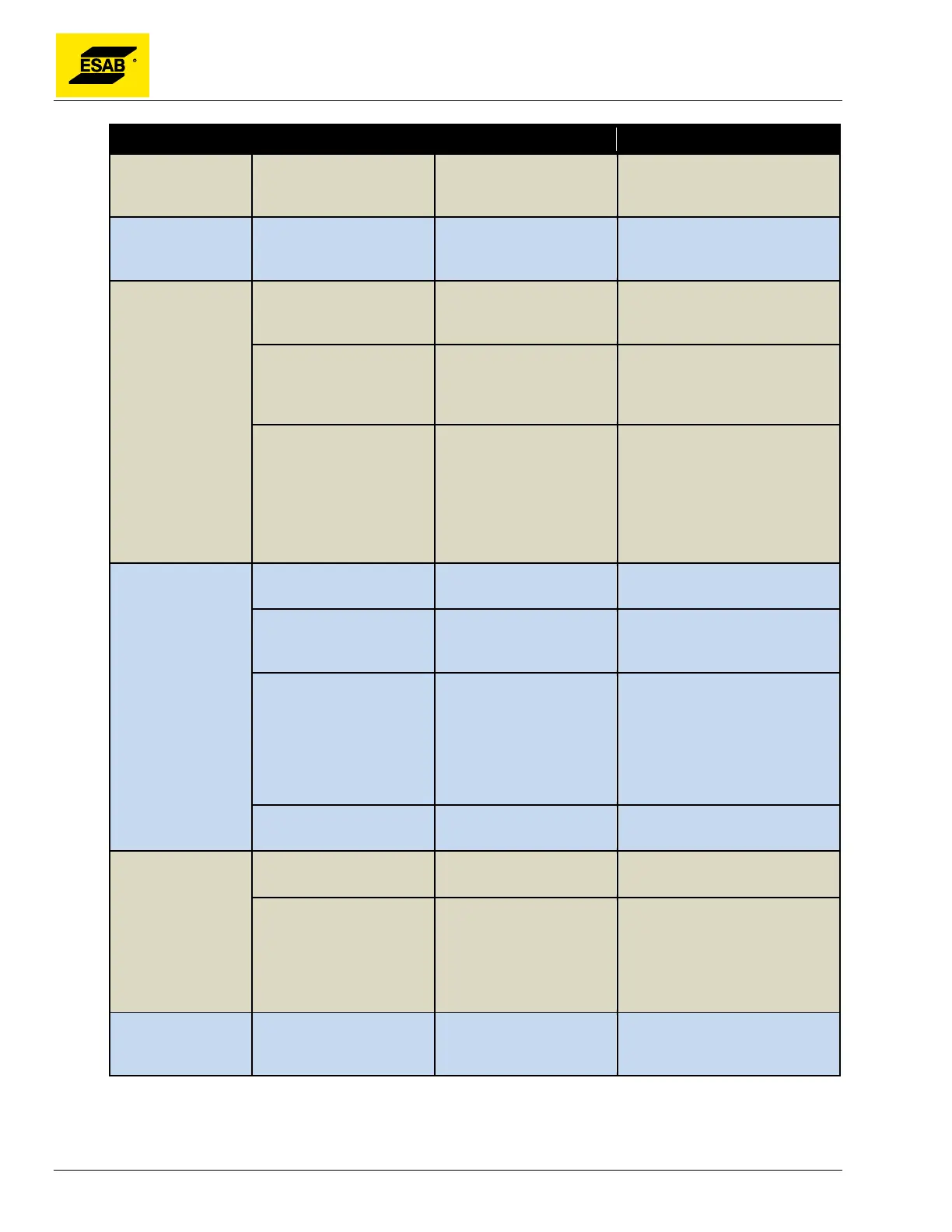

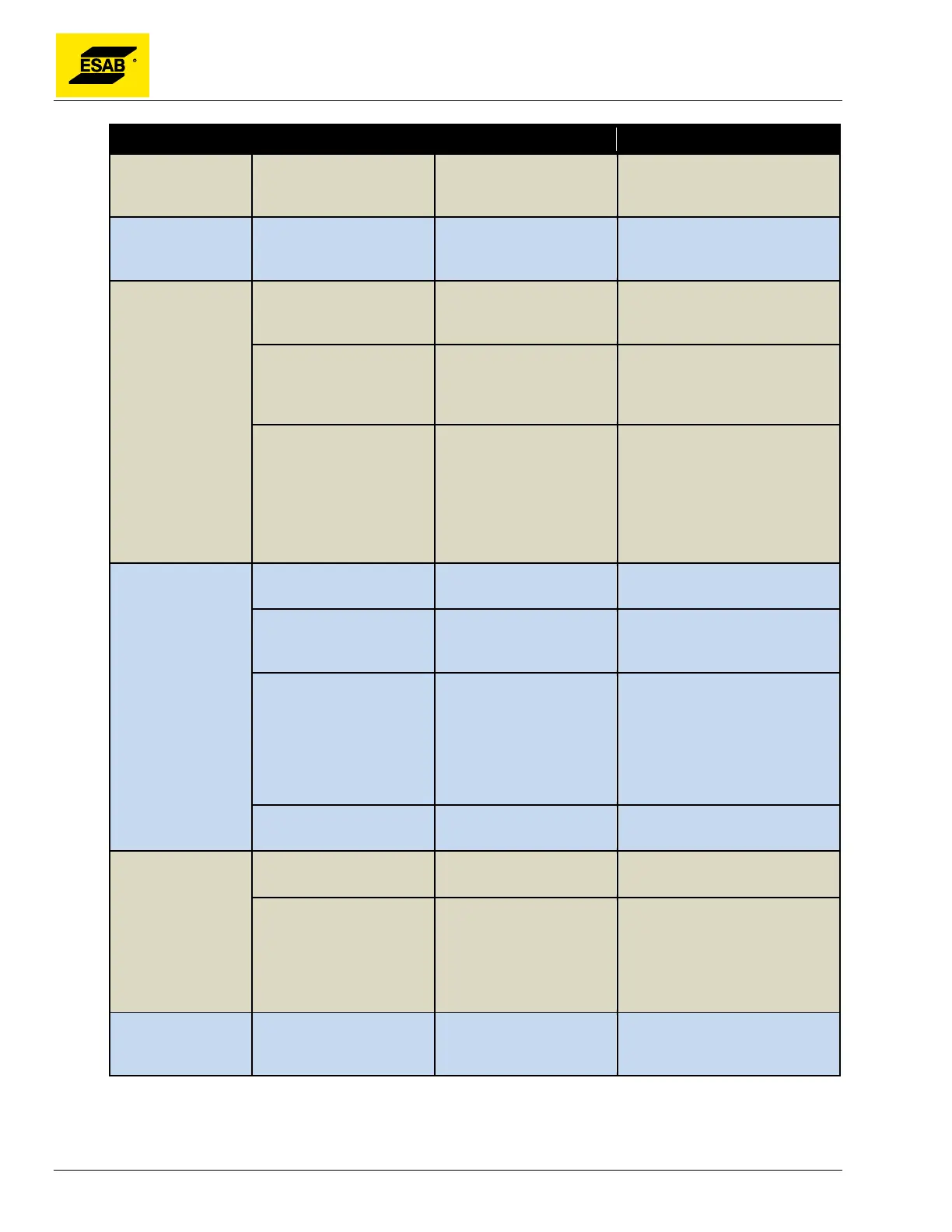

Fault Symptoms What To Check Possible Causes Recommended Solutions

On-screen graphics

look wrong

Check parameter settings Parameter may be set

incorrectly or parameters

may be corrupted.

Make sure Control P

Display Density is set to 0.

while running a part

Check parameter settings Parameter may be set

incorrectly or parameters

may be corrupted.

Make sure Control P

No-Graphics is set to 0 (OFF).

Machine suddenly

stops in the middle

of normal cutting

operations

Does it always stop at the

same position in every

program?

Part program may have

problem

Send the part program to the

programmer or to ESAB for

evaluation.

The CNC appears to be

running, but the torch has

stopped moving in one or

both axes.

Drive motor is jammed, or

drive has failed.

Make sure the machine is level.

Check the motors to make sure

they are still functioning

properly.

The CNC appears to be

running, but does not

respond to manual

panel or the Start or Stop

keys.

The CNC may be “locked-

up”.

a. Make sure plasma system is

properly grounded.

b. Check the incoming power

line to ensure power is not being

momentarily interrupted.

c. Remove power and re-boot

the control.

One of the motors

does not turn

Check wiring from drive

amp to motor.

Loose connection Secure all wiring connections.

Check the drive amplifier. Check for any alarms or if

the settings are not

correct.

Correct settings of drive amp.

Check settings of

SYSTEM parameters.

Check if Start Speed is

zero or too high, the

Acceleration Time is too

short, or Numerator and

Denominator settings are

set incorrectly or set to

zero.

Set the parameters to the

appropriate settings. Be sure to

record the original parameters

before making any modification.

Check motor to make sure

it is not frozen or jammed.

Motor may be damaged. Replace motor if damaged.

CNC is slow to

respond

Check the power supply. Output voltage may be

below the allowable range.

Adjust the output voltage or

replace the power supply.

Check settings of

SYSTEM parameters.

Corrupt or incorrect

parameters may cause

CNC operating issues.

Set the parameters to the

appropriate settings. Reset to

factory settings if necessary. Be

sure to record the original

parameters before making any

modification.

Travel limit alarm at

power-on

Check settings of

SYSTEM parameters.

Machine position may be

outside settings for Soft

Limits.

Increase settings for Soft Limits

if necessary.

Loading...

Loading...