ESAB Cutting Systems

CROSSBOW Page 140

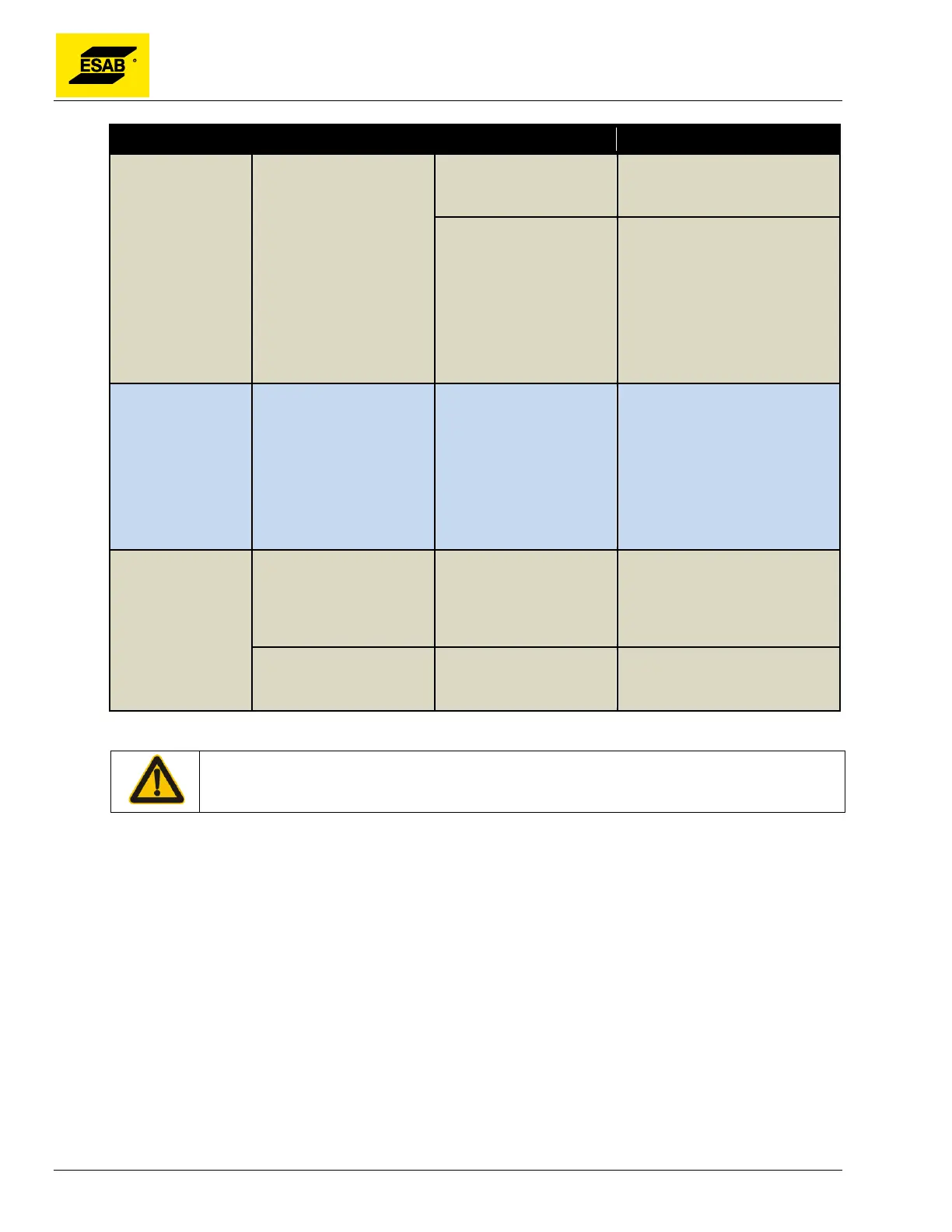

Fault Symptoms What To Check Possible Causes Recommended Solutions

The system will only

cut a straight line, it

will not cut a circle.

Select a different program

and test the system.

If the other programs will

run, there is a problem

with the original program.

Check the program.

If no program will run,

there may be a problem

with the parameter

settings.

Record the settings for

Numerator and Denominator in

the SYSTEM Parameters. Then

reset the factory parameters.

Reboot the system and then re-

enter the recorded values for

Numerator and Denominator.

Save the parameters and test

the system performance.

Screen blinks when

the Cut Oxygen

solenoid valve

opens, or when

plasma arc starts.

Check ground

(Work/Table) connection

of the Initial Height

Sensing cable.

Electrical noise, loose

ground connection.

Make sure ground connection is

tight, and is making good

electrical contact. Make sure all

cables are connected properly

and are in good condition.

NOTE: This machine is not

recommended for use with

plasma systems that utilize a

high-frequency starting arc.

Outputs do not turn

on when indicated

on screen (Cut-Oxy

Solenoid or Plasma

Start)

Check 24 Volt power

supply. Measure voltage

between wires labelled

24V and 24G at the Main

Power Supply.

If missing 24 Volts DC,

power supply may have

failed.

Check and replace the Main

Power Supply.

Check if the four relays on

rear of CNC Unit.

Relay may be loose or un-

seated in socket, or may

have failed.

Re-seat or replace relays.

Warning

There is the hazardous voltage inside the device. All servicing should be referred to a

qualified service technician.

Loading...

Loading...