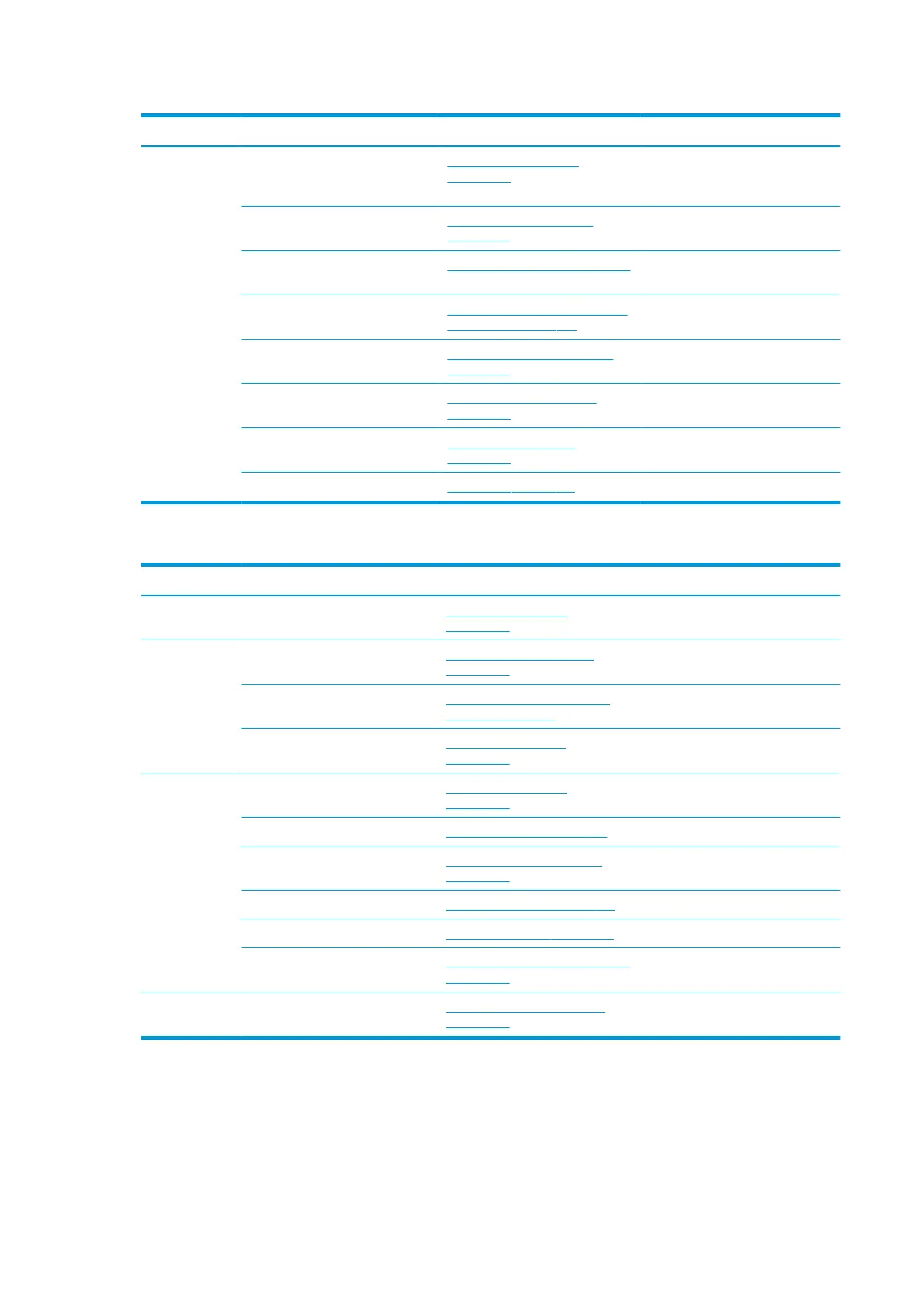

Table 8-1 Maintenance operations for all substrates (continued)

Frequency Maintenance operation Cross-reference Part number and description

Replace an e-cabinet fuse Replace an e-cabinet fuse

on page 260

CZ056-67136: E-cabinet PCA Fuses

Kit, included in the Standard Uptime

Kit

Clean the printhead pocket and

electrical contacts

Clean the printhead contacts

on page 262

HP Latex 3000 Printer Cleaning Kit,

provided with your printer

Replace a spindle valve Replace a spindle valve on page 267 Q6702-67025: Spindle air valve,

included in the Standard Uptime Kit

Clean the roll-to-free-fall roller and

pinchwheels

Clean the roll-to-free-fall roller and

pinchwheels on page 269

Clean the carriage rails manually Clean the carriage rails manually

on page 270

Grease the printhead primers Grease the printhead primers

on page 272

Pinch clamp replacement Pinch clamp replacement

on page 285

Rocker pads Rocker pads on page 293

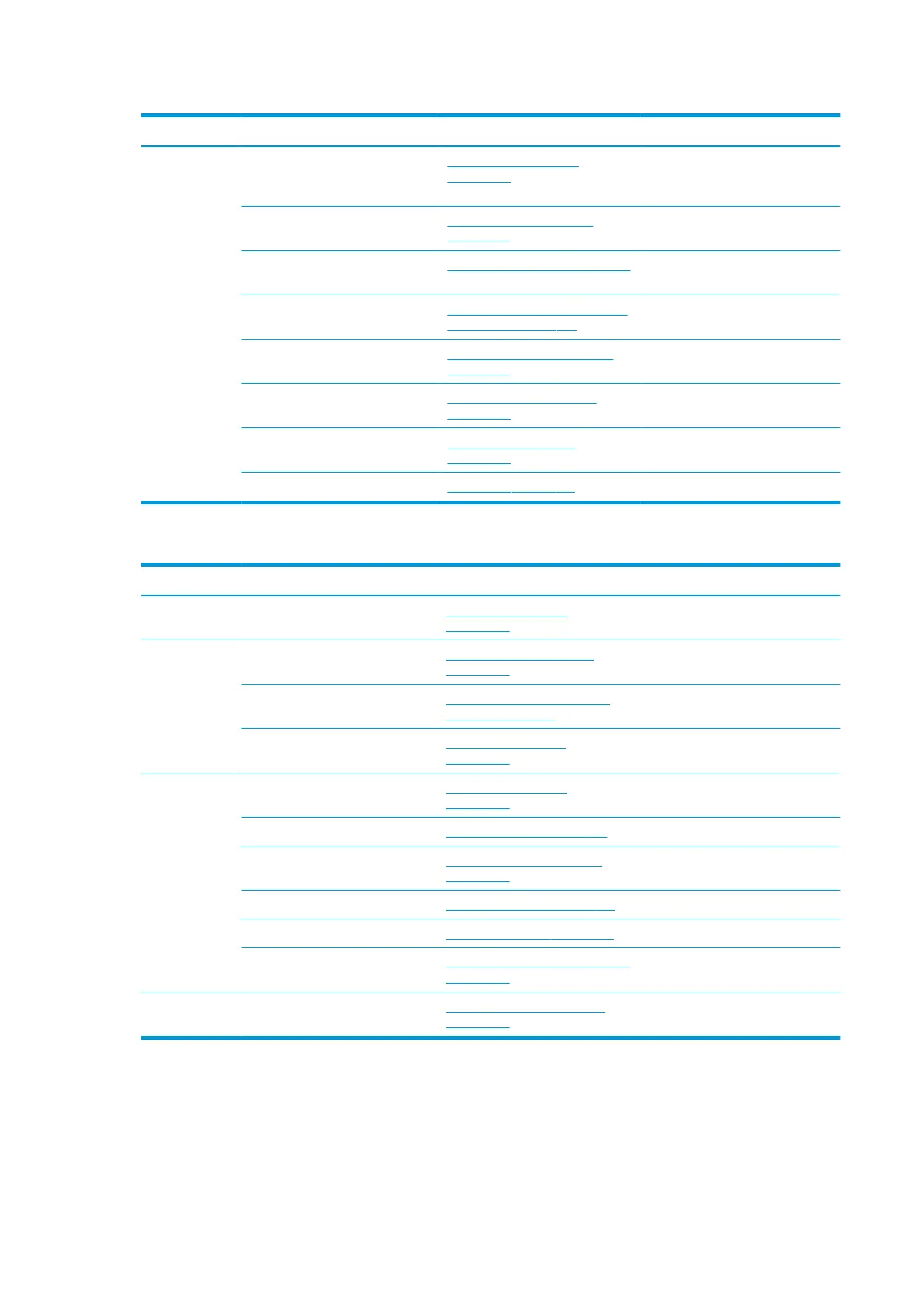

Table 8-2 Additional maintenance operations for porous substrates

Frequency Maintenance operation Cross-reference Part number and description

Every 7 liters of

ink

Clean the aerosol lters Clean the aerosol lters

on page 274

At the end of

each roll

Wipe the top of the protector Wipe the top of the protector

on page 287

Wipe the ribs of the ink collector

modules

Wipe the ribs of the ink collector

modules on page 288

Clean the output platten Clean the output platen

on page 207

After

uninstalling the

ink collector kit

Clean the aerosol lters Clean the aerosol lters

on page 274

Wipe the protector Wipe the protector on page 288

Wipe the ink collector modules Wipe the ink collector modules

on page 289

Printer maintenance Printer maintenance on page 289

Clean the print zone Clean the print zone on page 166

Clean the substrate-advance sensor Clean the substrate-advance sensor

on page 231

Every 34 liters of

ink

Replace the ink collector foams Replace the ink collector foams

on page 292

164 Chapter 8 Hardware maintenance ENWW

Loading...

Loading...