4. If you are using the roll-to-free-fall conguration, check that the knob is released to ensure substrate

tension.

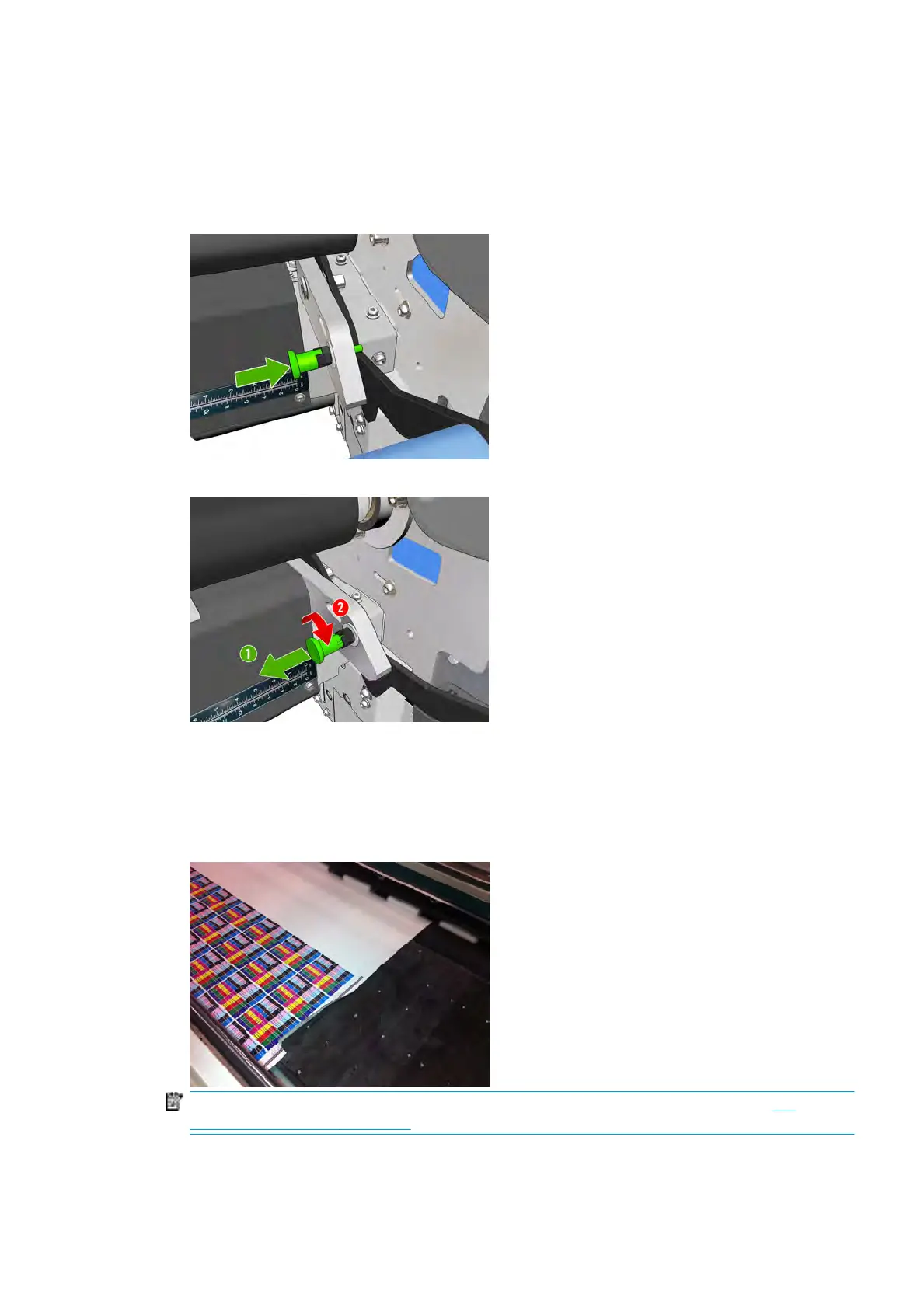

When printing in the roll-to-free-fall conguration and you see diagonal smears of ink, the substrate

may have been badly loaded; or the tension roller may be causing wrinkles in the substrate. In the latter

case, you can try using the tension roller knob to reduce the pressure that the roller exerts on the

substrate, as shown below:

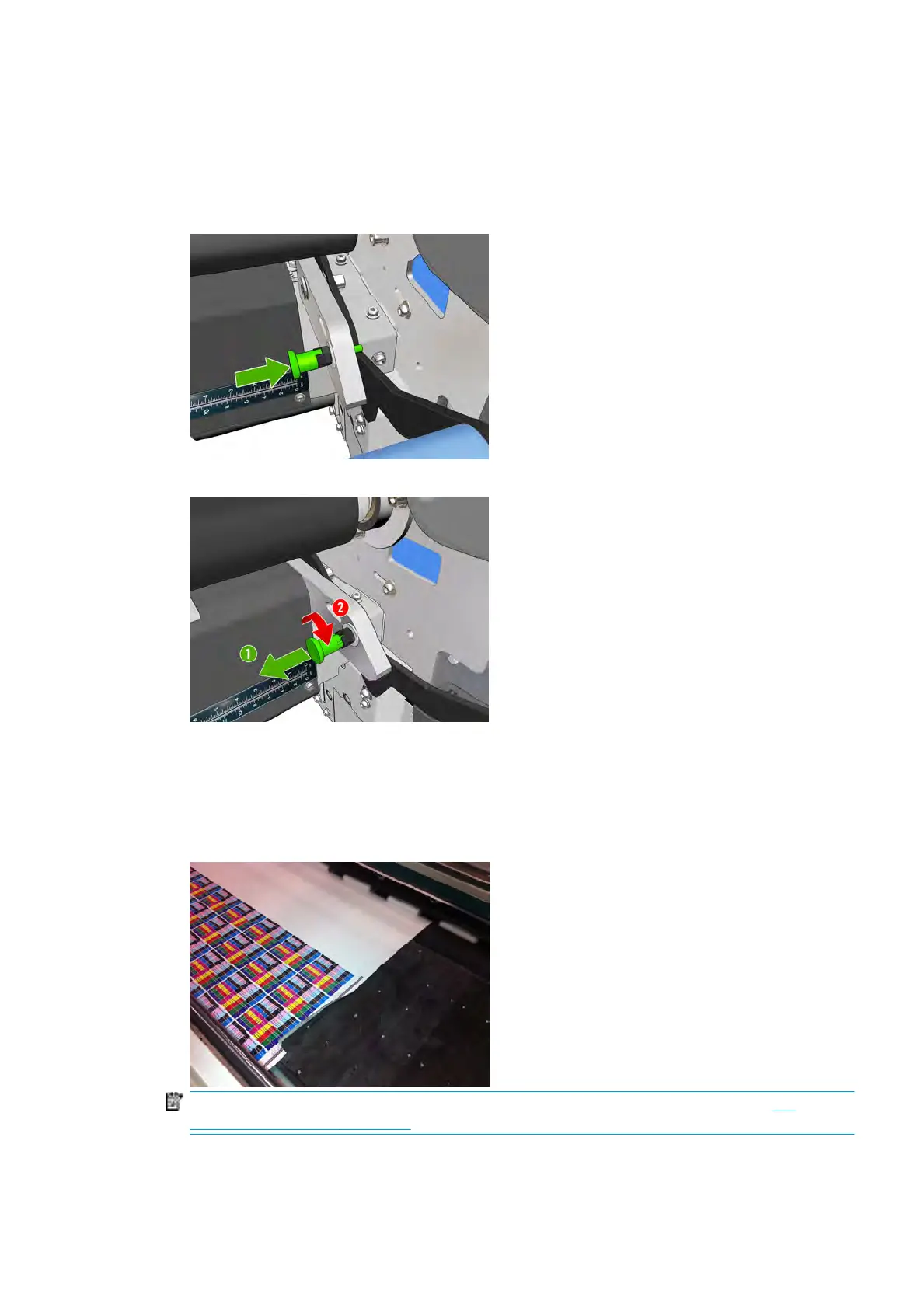

To restore the tension roller pressure to normal, pull the knob and turn it as shown below.

5. R

eload the substrate and try to minimize skew while loading. Check that you are loading the substrate

using the correct procedure.

6. If you have experienced a substrate crash because the lateral edge of the substrate in the print zone is

not at enough, and is raised or even partially cut because you are not using edge holders, then you are

recommended to use them.

NOTE: If y

ou are already using edge holders, check that they are correctly positioned (see

The

substrate edge holders on page 33).

7. T

ry reducing the drying power and curing temperature.

ENWW Printing issues 301

Loading...

Loading...