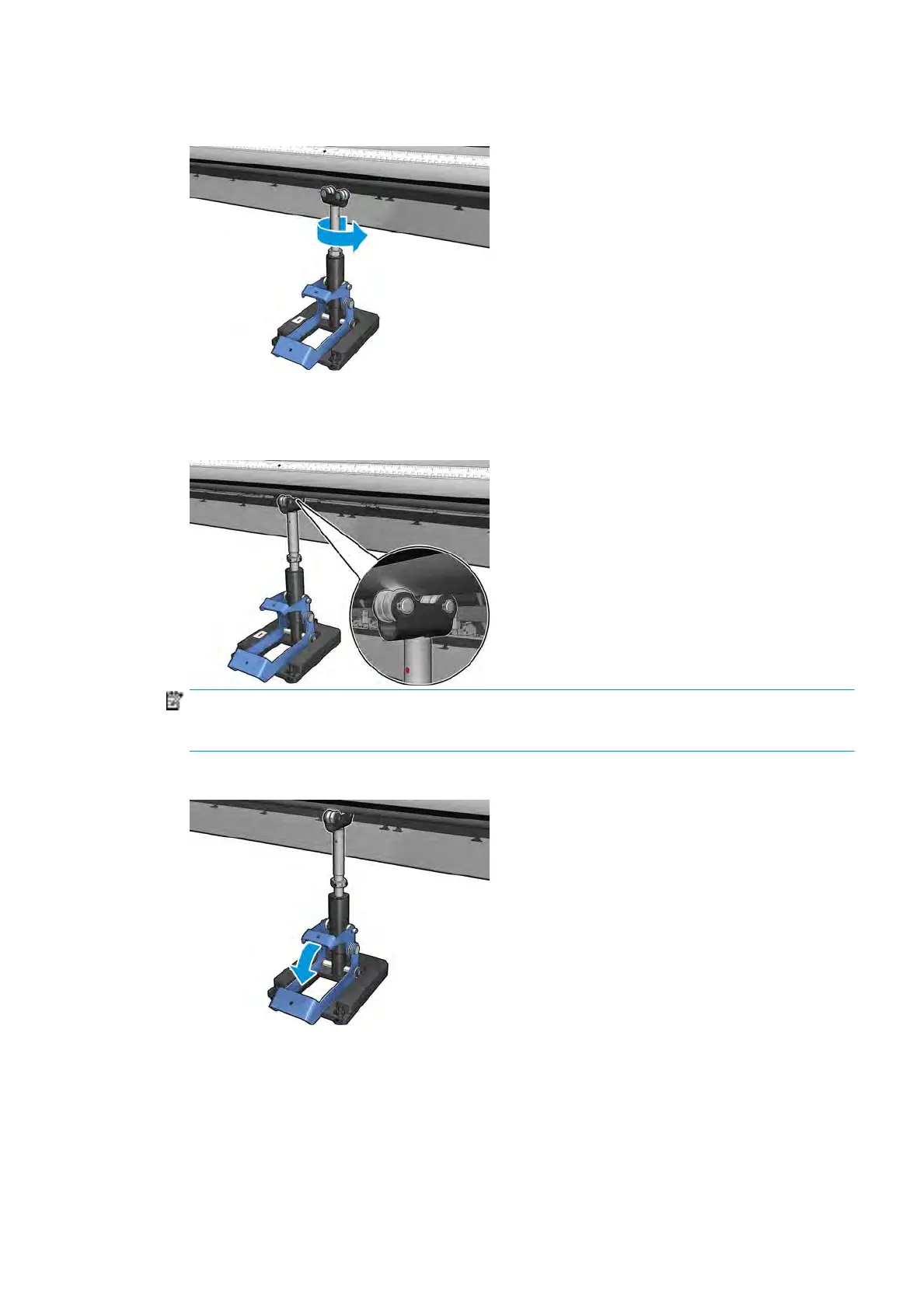

4. Adjust the height of the support by turning it counterclockwise. The bearings at the top of the dual-roll

center support must touch the spindle.

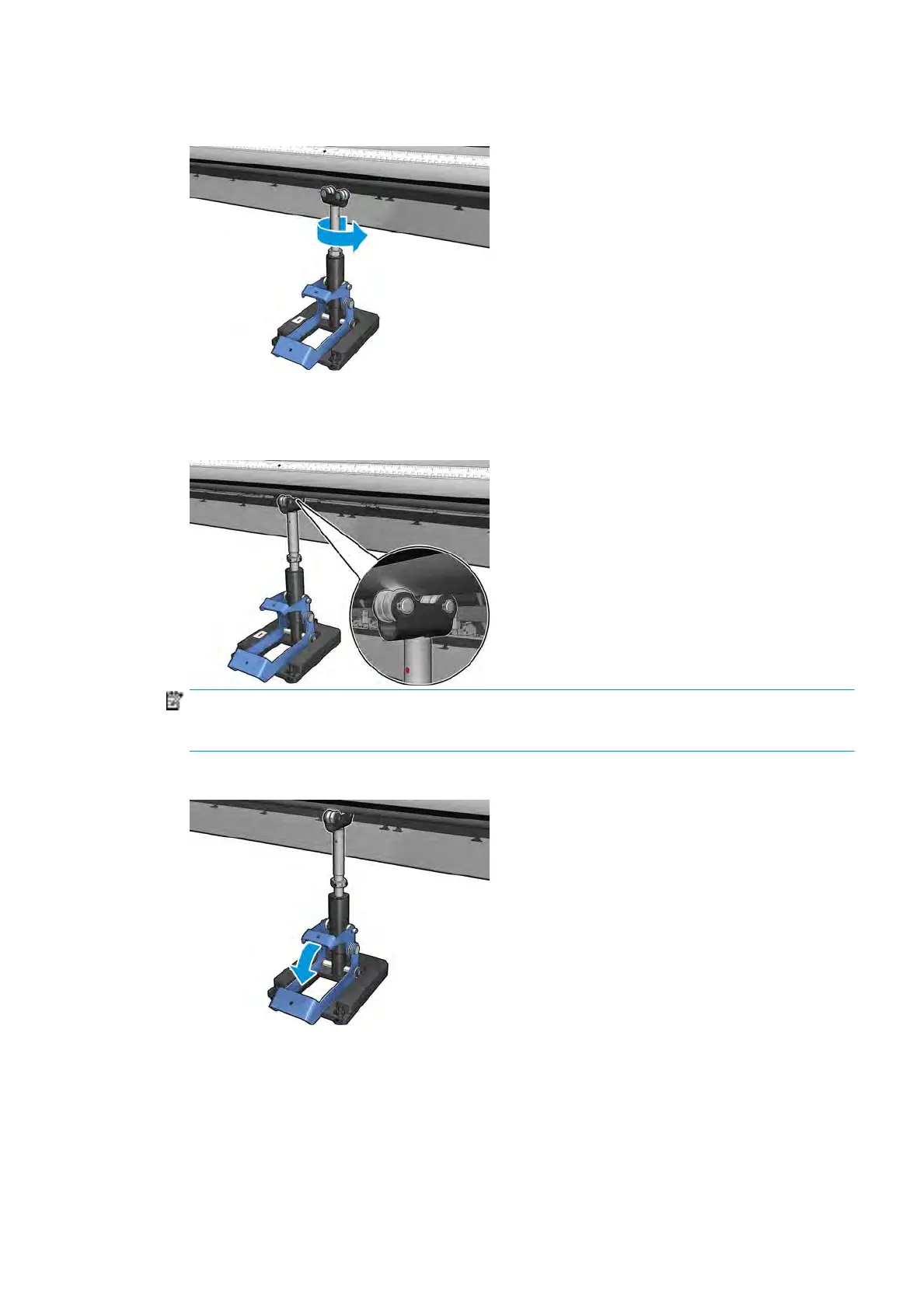

5. Manual

ly turn the spindle 360 degrees. Make sure there is full contact between the bearings on the

support and the face of the spindle except along the ruler groove and pneumatic groove. Turn the

bearings on the support. If you cannot turn them, lower the height of the support.

NOTE: If a r

ed groove is visible in the thread of the support shaft, it has reached its maximum limit. Do

not turn. Adjust the height using the three height screws under the support base. Tighten the three

hexagonal nuts on the top of the support base to lock the three height screws.

6. Pul

l the small lever down.

ENWW Dual roll split spindles printing issues 307

Loading...

Loading...