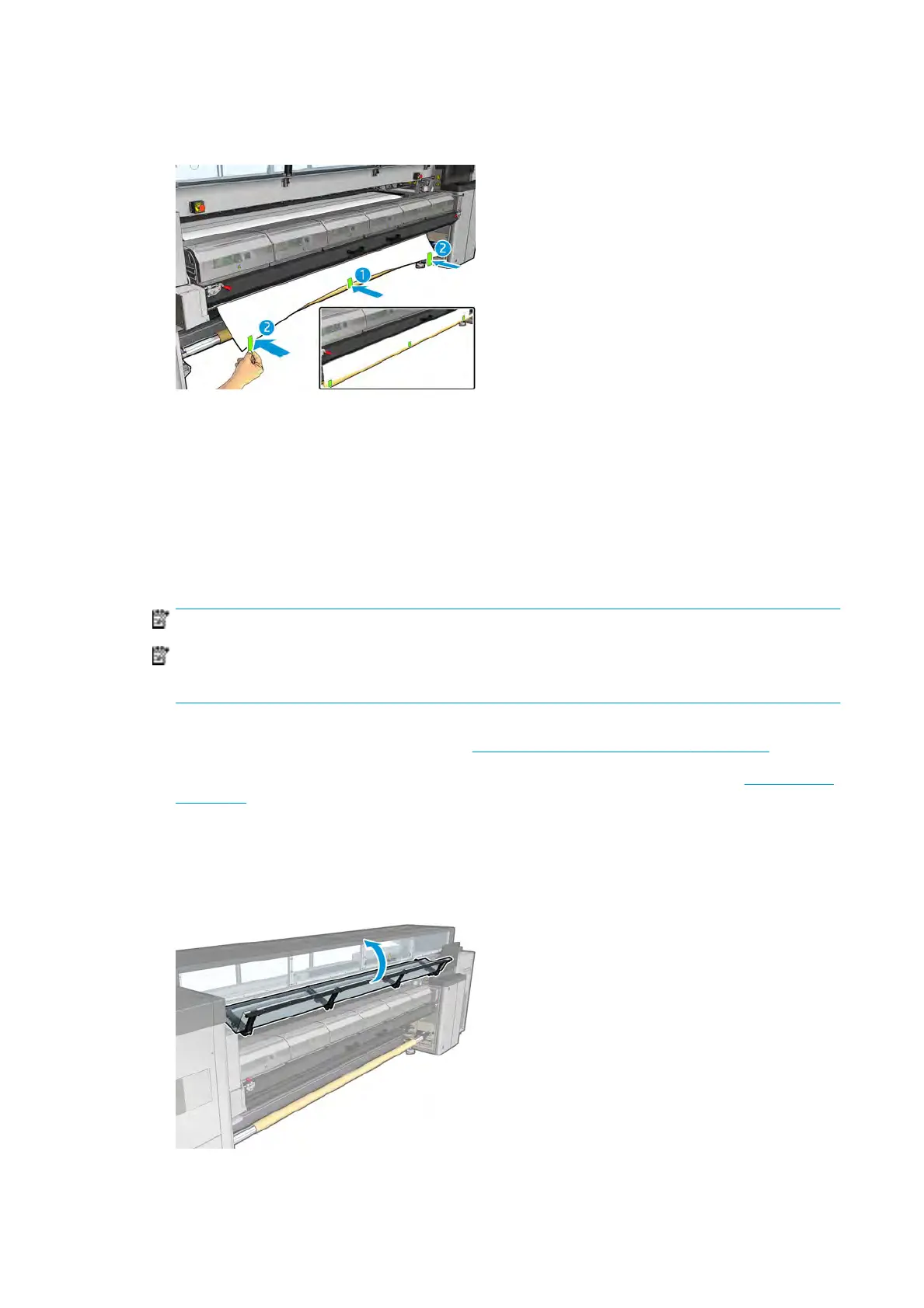

14. When the substrate is evenly tensioned and at (no wrinkles or bumps), attach it to the empty core with

adhesive tape. Tape it rst in the center, and then at the left and right sides, making sure not to pull the

substrate excessively or leave it wrinkled.

15. If y

ou are using them, place the substrate edge holders into position and attach them at the front.

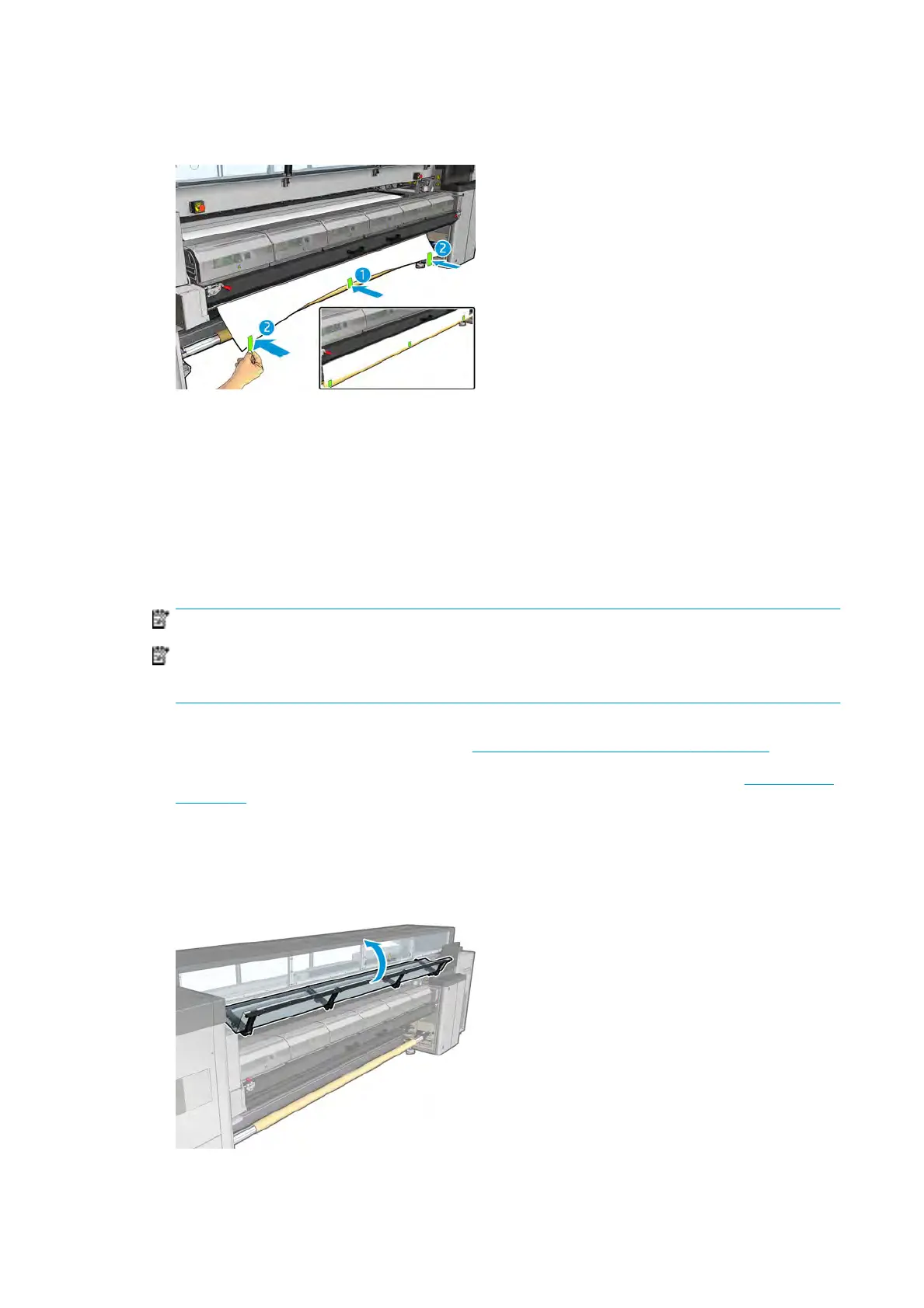

16. Close the curing module and latches, then the front door.

17. If you are using them, attach the substrate edge holders at the rear.

18. Close the loading table and latches.

19. Go to the Internal Print Server and press the Finish button. The printer rotates both rolls to check their

diameters, and it also checks the width of the roll, the winding direction, the vacuum, and the substrate

advance calibration (this takes about a minute).

NOTE: The roll size appears at the bottom of the screen; to change it, click Change substrate settings.

NOTE: Some subs

trates (such as transparent substrates) cannot be measured by the printer in this

way. In such cases, you will be asked to enter the Left Edge and Width elds yourself into the Internal

Print Server. Use the ruler on the spindle to check these values.

20. An al

ert about substrate-advance tracking may appear at this point. For more information on when you

might want to turn o automatic tracking, see

Substrate-advance compensation on page 146.

21. F

or more information on when you might want to change the carriage beam position, see

Substrate tips

on page 29.

Manual l

oading

1. Use the Internal Print Server to raise the carriage beam to its loading position.

2. Open the front door.

60 Chapter 3 Handle the substrate ENWW

Loading...

Loading...