Aer the pole posion

idencaon has been completed successfully...

...the controller is inhibited automacally and the pole posion determined for the acvated

feedback system is set in the 0x2C03:002 object.

•

Sa

ve the changed

sengs.

The »EASY Starter« serves to save the parameter sengs of the servo inverter as parame-

ter le (*.gdc). This le can then be imported in the »PLC Designer«. Saving the parameter

sengs

•

The in

verter disable set

automacally by the procedure can be deacvated again via the

CiA402 control word 0x6040. Enable operaon

Adapt pole posion idencaon PLI (min. movement)

The process of pole posion idencaon described above can be adapted to the respecve

machine and the exisng moments of inera by using the parameters described in the follow-

ing.

NOTICE

Thermal overload of the motor!

The mot

or may be permanently damaged.

▶

If no temperature monitoring is available in the motor, and/or the I²xt motor monitoring

and the maximum current monitoring are not parameterised correctly, the motor can be

permanently damaged if the current amplitude is set too high!

▶

Motor overload monitoring (i²*t)

▶

Overcurrent monitoring

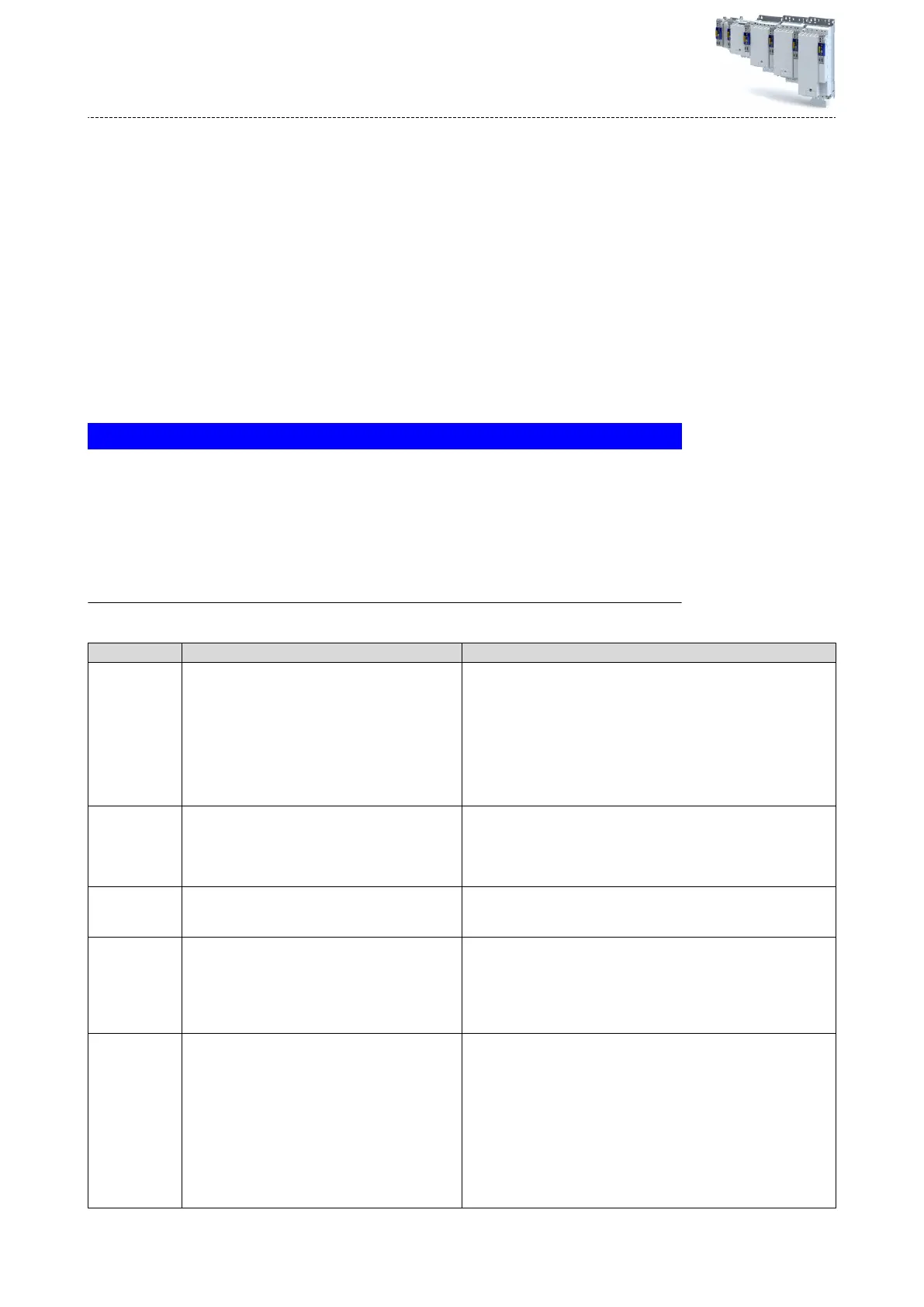

Parameter

Address Name / seng range / [default seng] Info

0x2C62:001 Pole posion

idencaon (min. movement) sengs:

Current amplitude

1 ... [25] ... 1000 %

•

Seng can only be changed if the inverter is inhibi-

ted.

Percentage adaptaon of the current amplitude.

•

For large machines, high mass inera values or for linear direct drives,

the current amplitude usually must be increased.

•

Default seng 25 % ≡ 35 % of Motor rated current (0x6075)

Note!

If the current amplitude is set to > 100 %, the device ulisaon (Ixt)

monitoring and/or one of the motor monitoring funcons may respond

and cause the abort of the pole posion idencaon.

0x2C62:002 Pole posion

idencaon (min. movement) sengs:

Ramp me

1 ... [10] ... 600 s

•

Seng can only be changed if the inverter is inhibi-

ted.

Percentage adaptaon of the rate of current rise.

0x2C62:003 Pole posion idencaon (min. movement) sengs:

Gain

0 ... [0] ... 1000 %

Adaptaon of the proporonal PI controller gain.

With the Lenze seng "0 %",the PI controller works as an I controller.

0x2C62:004 Pole posion idencaon (min. movement) sengs:

Reset me

0.1 ... [62.5] ... 6000.0 ms

Adaptaon of the reset me of the PI controller.

•

In order to be able to compensate a posional variaon faster, rst

the reset me should be reduced. If this does not result in the desired

behaviour, the proporonal gain can be increased.

•

Ensure that the posion control does not get unstable. We therefore

recommend you to use an I controller.

0x2C62:005 Pole posion idencaon (min. movement) sengs:

Max. move permied

1 ... [20] ... 90 °

Adaptaon of the permied movement.

•

The pole posion idencaon comprises a monitoring funcon for

the follow-up control. If a movement greater than the permissible

movement set is detected by the encoder system, the pole posion

idencaon is aborted and the error response parameterised is trip-

ped:

•

In order to detect a non-permissible blocking of the machine, a posi-

ve and negave test angle relave to the current posion are

dened aer the idencaon. The machine must align itself to these

two test angles within a tolerance of 25 %. The size of the test angle

corresponds to the max. move permied set here.

Conguring the feedback system

S

ynchronous motor: Pole posion idencaon (PPI)

Pole posion idencaon (PPI) with minimum movement

232

Loading...

Loading...