Diagnostic information 2-35

5061

200.96 paper jam service check

Neither the S2 nor narrow media sensor broke in time.

Note: See “Printer sensors” on page 5-3.

201.xx and 202.xx paper jam service check

Step Actions and questions Yes No

1 Make sure the media installed in the tray meets

specifications.

Does the media meet specifications?

Go to step 2 Inform the

customer that

media loaded in

Tray x does not

meet

specification.

2

Check tray for the edge guide setting and media

loading. Edge guides should be adjusted against edge

of media. Media should be fanned and lay flat in the

tray.

Is the media properly loaded in the tray?

Go to step 3 Properly load

media.

3

Remove the ITU and check for the jam at the second

transfer roll.

Is paper jammed at the second transfer roll?

Clear the jam. Contact your next

level of support.

Step Actions and questions Yes No

1 Remove the fuser from the printer. Remove the oiler

housing from the fuser, and pivot the paper guide up.

Is media jammed inside the fuser?

Clear the jam

from the fuser.

Go to step 2

2

Check fuser exit sensor flag.

Does flag rotate freely and return to normal position

when released?

Go to step 4 Replace the fuser

assembly. See

“Fuser

assembly

removal” on

page 4-44.

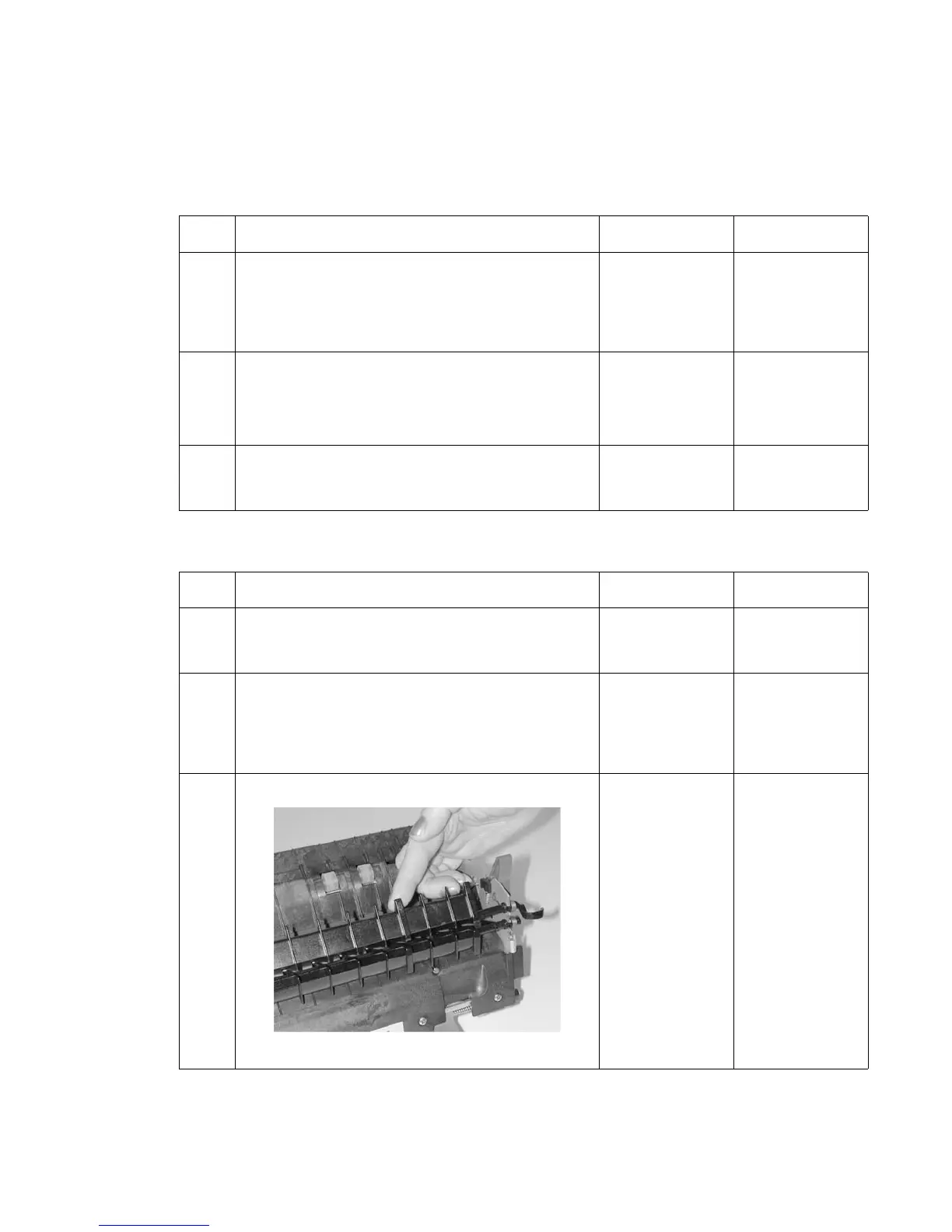

3

Check that the deflector gates in the fuser rotate freely.

Do the deflector gates rotate freely?

Go to step 4 Replace the fuser

assembly. See

“Fuser

assembly

removal” on

page 4-44.

Loading...

Loading...