12 • _CONF – Device configuration and I/O Subject area Parameter Description MC6000/7000

_ENCD

_VAL

Index

_VFCON

_PMOD

_KPAD

Contents

Introduction

_SIO

_SCTY

_REF

_SYS

_IO1

_IO2

_CAN

_OPT1

_MOT

_CONF

_TCON

_SCON

_PCON

465-BRAKE - Actuation mode for motor brake

Source: Brake mode

Function: Parameter only on MC7000.

Operation mode of holding brake, activation with function selector FOS03

1) Depending on the window for motor standstill, parameter SPD_0 (_CONF)

Values:

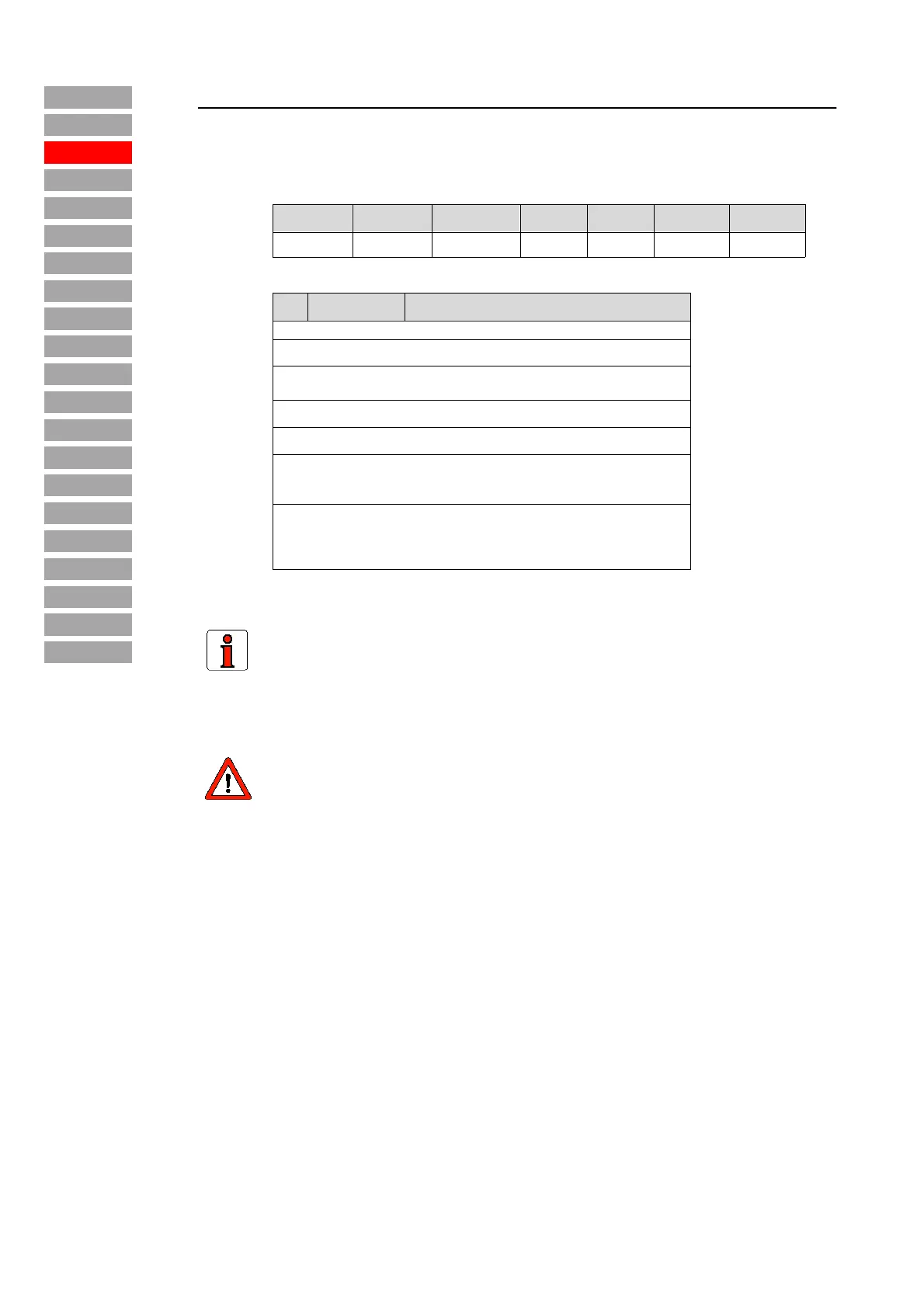

Minimum Maximum Factory set. Unit MODE SMARTCARD Type

SPD_0 HOLD2 HOLD2 – R1W2 APPLI USIGN8

Settings:

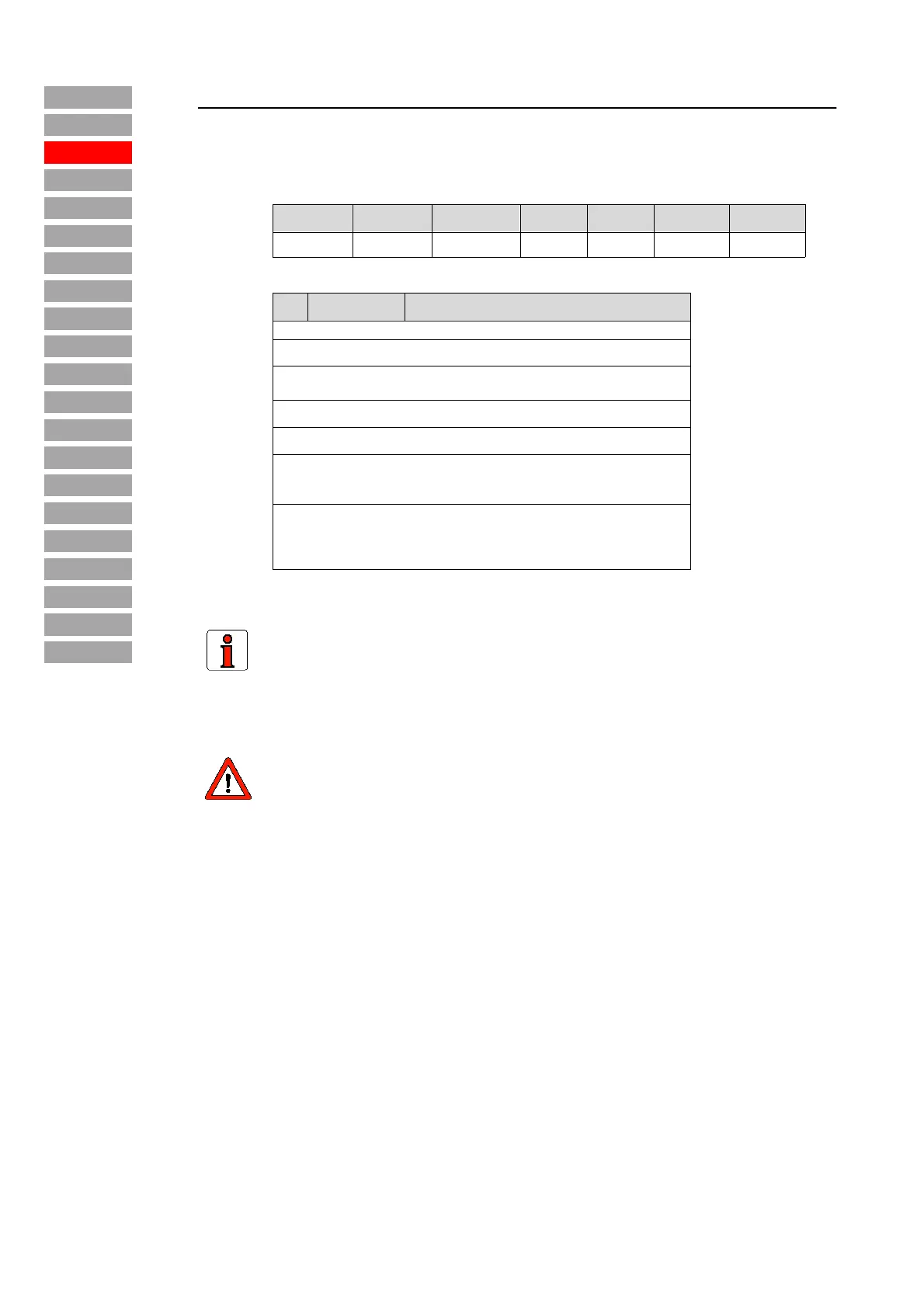

No. Setting Holding brake engages when ...

0 SPD_0 motor is stopped 1) and control is disabled.

1 ERR_1 an error occurs and the motor is stopped 1).

2ERR_2

an error occurs and the motor is stopped 1) or no

later than 400 ms after occurrence of the error.

3 ERR_3 an error occurs (immediate).

4 HOLD the start signal is removed

5HOLD1

the motor is stopped 1) or when an error occurs

(immediate). When the holding time 467-THTDC

expires the control is shut off.

6HOLD2

the motor is stopped 1) or when an error occurs

and the motor is stopped or after no more than

400 ms. When the holding time 467-THTDC

expires the control is shut off.

Note:

On restart the holding brake is only released when the motor ready to start, i.e.

when the flux build-up phase in asynchronous machines is complete.

Attention!

With settings ERR_3 and /START the holding brake is always activated immediately,

regardless of the current motor speed. Braking at high speeds impairs the durability

of the brake, however. Depending on the external moment of inertia, this may result

in the brake sticking and so damage the motor ("breakdown braking"). This is

accepted as a reasonable risk in many safety devices.

The durability of the holding brake types in the form of the maximum permissible

braking energy (lifetime switching) is given in the M

ASTERDRIVE data specification

booklet and must always be taken into account in parameter setting (commission-

ing) !

Loading...

Loading...