214323 88 Revision B

Adjusting Feed Draper Speed

The feed draper moves the cut crop from the side drapers into the adapter feed auger.

Figure 3.100: CA25 Combine Adapter

Adapter feed draper (A) is driven by a hydraulic motor and a

pump that is powered by the combine feeder house drive

through a gearbox on the adapter.

The feed draper speed is determined by the combine feeder

house speed and cannot be independently adjusted.

3.7.8 Knife Speed

The header knife drive is powered by the adapter hydraulic pump which is driven by the combine feeder house. There is no

separate adjustment to control the knife speed.

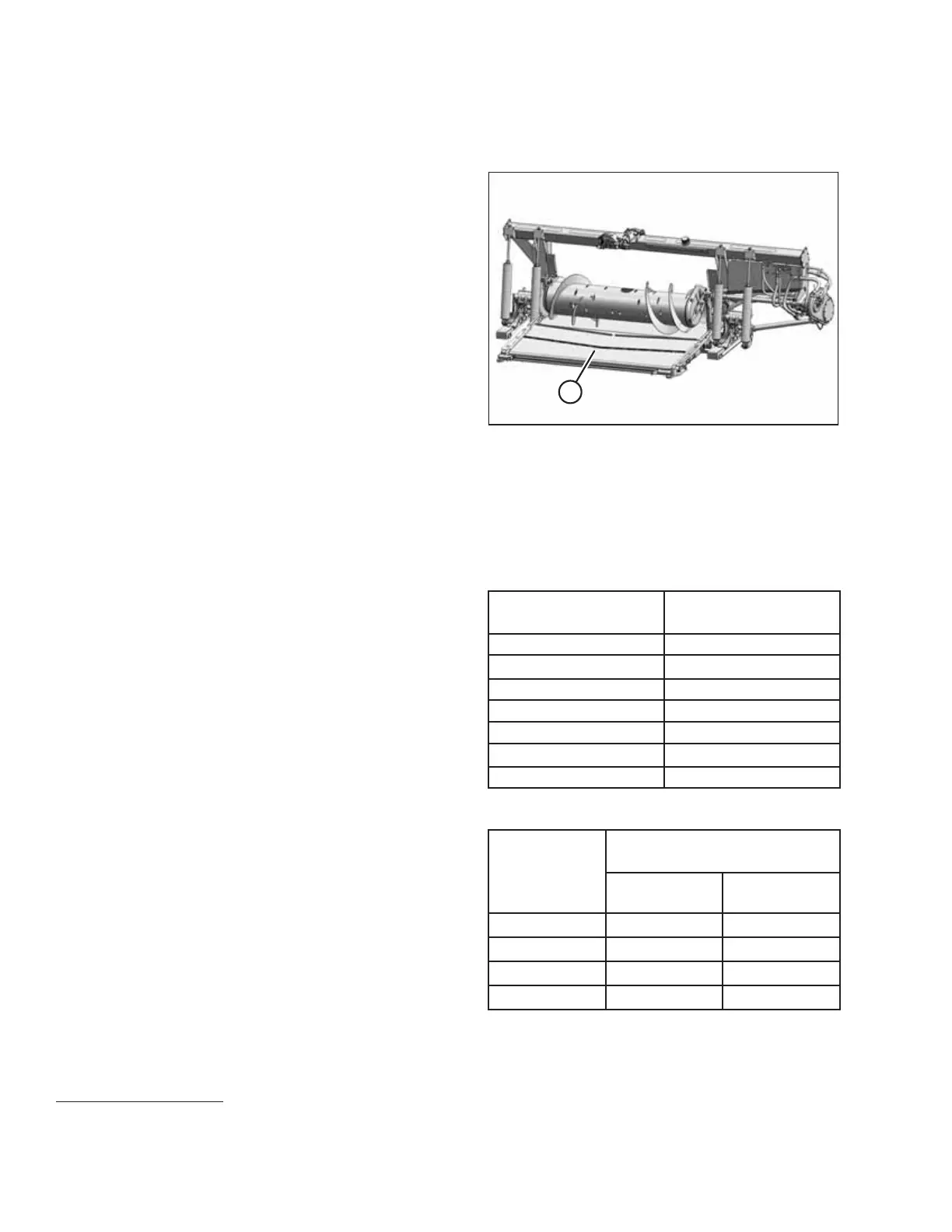

Table 3.8 Feeder House Speed

Combine

Feeder House Speed

(rpm)

Case IH 580

Challenger

®

625

CLAAS

33

420

Gleaner

®

625

John Deere

490

Massey Ferguson

®

625

New Holland

580

IMPORTANT:

For variable speed feeder houses, the rpm values shown at right

represent the MINIMUM feeder house speeds. Reduce the flow

to the knife drive motor if operating above these rpm values to

prevent knife overspeeding and knife failure.

Table 3.9 FD75 Header Knife Speed

Header Size (m

[ft.])

Recommended Knife Drive Speed

Range (rpm)

Single-Knife

Drive

Double-Knife

Drive

9.1 m (30 ft.)

600–700

—

10.7 m (35 ft.)

550–650

—

12.2 m (40 ft.)

525–600 550–700

13.7 m (45 ft.)

—

550–700

IMPORTANT:

Ensure the knife speed is within the range of rpm values in

Table 3.9, page 88. Refer to Checking Knife Speed, page 89.

IMPORTANT:

Under normal cutting conditions, knife speed taken at the

knife drive pulley should be set between 600–640 rpm

(1200–1280 spm). If set to the low side of the range, you

could experience knife stalling.

OPERATION

33. The rear shaft speed on CLAAS combines is 420 (speed shown on cab display monitor also will be 420). The output

shaft speed is actually 750 rpm.

Loading...

Loading...