TM Palletizing Operator User’s Manual Product Version: 1.0 / Document Version: 1.0 155

True: enable gripper sensor feedback detection

False: disable gripper sensor feedback detection

Table 30: Advanced setting for general parameters

WARNING:

1. Users may enable sensor detection function in parameter settings to prevent robot elbow

from colliding with boxes accidentally.

2. Users may enable air source sensor detection function in the parameter settings to pause

the system. They shall also confirm the air source sensor setting. If the system shows “Air

Source Pressure Too Low” message, it will cause PAUSE.

3. When the robot is operating over its joint limit (usually J6), it will cause the robot to stop its

operations immediately. User can set different approach value in palletizing setting to

avoid the joint limit issue.

Caution:

1. The palletizing system will pause if the robot fails to grab the box. The system will show

“Grab fail cause pause! Resume after checking” message.

2. If the tool’s electric wire is disconnected when the robot has grabbed the box, it will

continue to grab the box. However, the system will show “No box detected on gripper,

cause PAUSE” message. For details, please see Appendix – A: Troubleshooting and

Error

3. If visual recognition fails due to light distraction from the environment, the palletizing

system will pause and the robot will not be able to grab the box. The system will show

“Grab fail cause pause! Resume after checking”. For details, please see Appendix – A:

Troubleshooting and Error

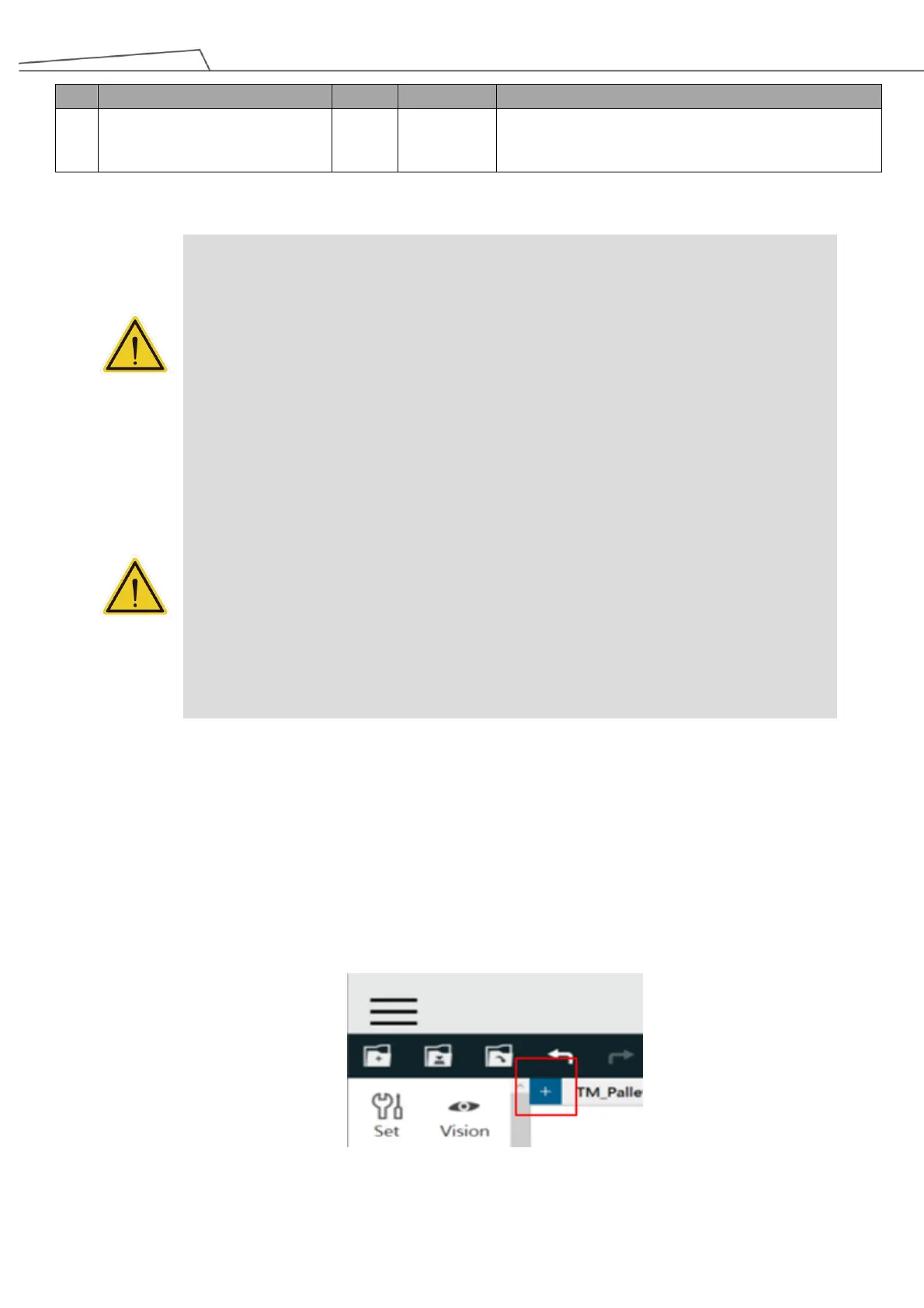

6.6.2 Advanced2-8

Advanced2-8 settings are programmed with editable subflows offering additional, flexible configurations for

users to edit their gripper use, sensor, interval between layers, offset point, placement, approaching vector or

barcode scanning. In general, users can create new subflows with Advanced2-8.

The following provides an example:

1. Click “+” icon to add a subflow.

Figure 154: Add a subflow

Loading...

Loading...