TM Palletizing Operator User’s Manual Product Version: 1.0 / Document Version: 1.0 45

The speed limit of the tool center point can be set. When the robot

exceeds its set value, it will trigger a protective stop.

The additional force that TCP received after compensating the

weight of tool in TCP setting and weight of workpiece in payload

setting in the programming. The force limit of the tool center point

can be set. When the robot exceeds its set value, it will trigger a

protective stop. The force of the tool center point is the external force

at the tool center point estimated through the model by the robot

system. It is not the protection value of applied external force at the

tool center point by the robot system.

Provides a safety function for users to set Cartesian limits to the

robot. Cubical and cylindrical limits can be set, and both TCP and

elbow are monitored.

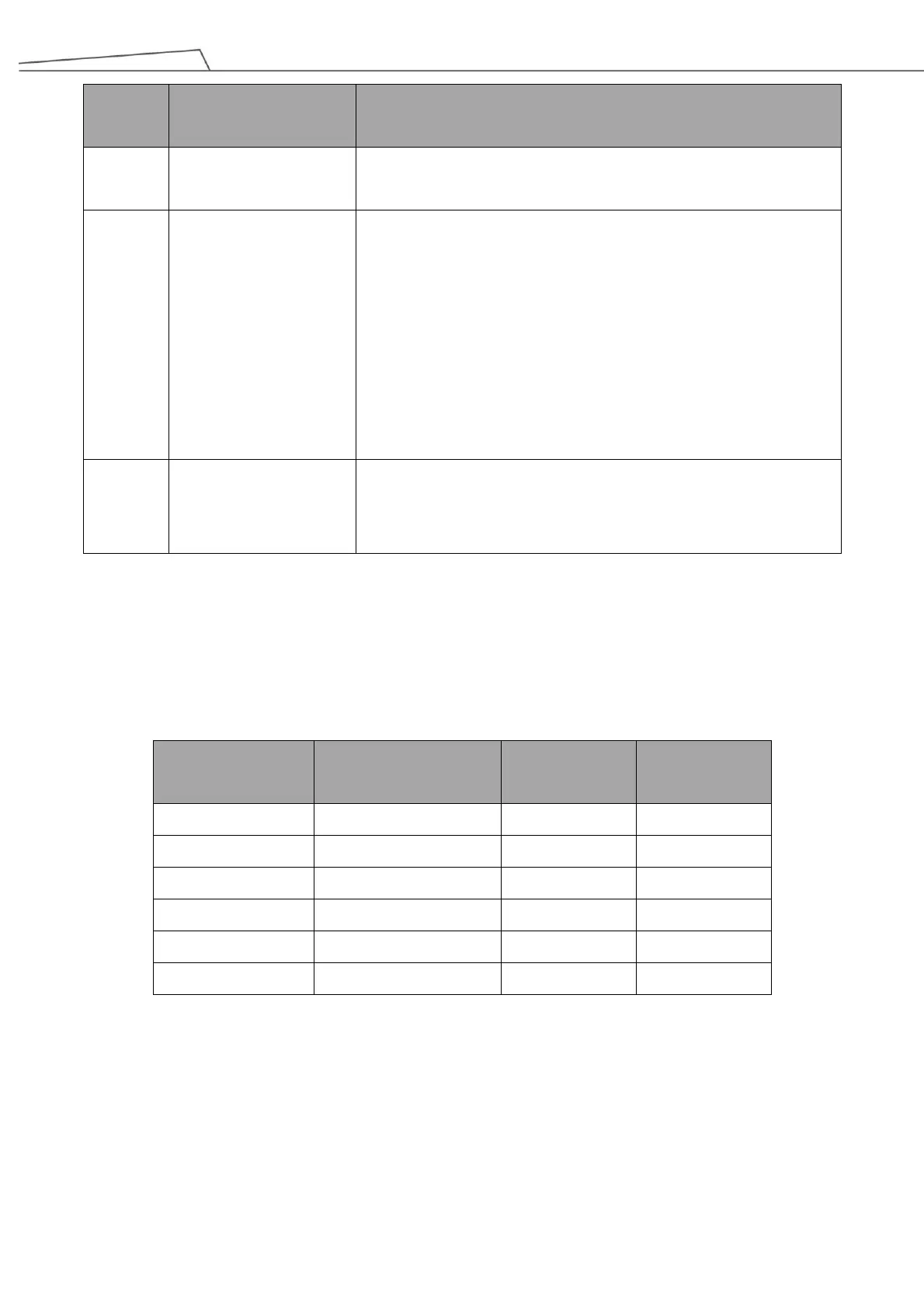

Table 13: Safety Function SF10~SF15 Definitions

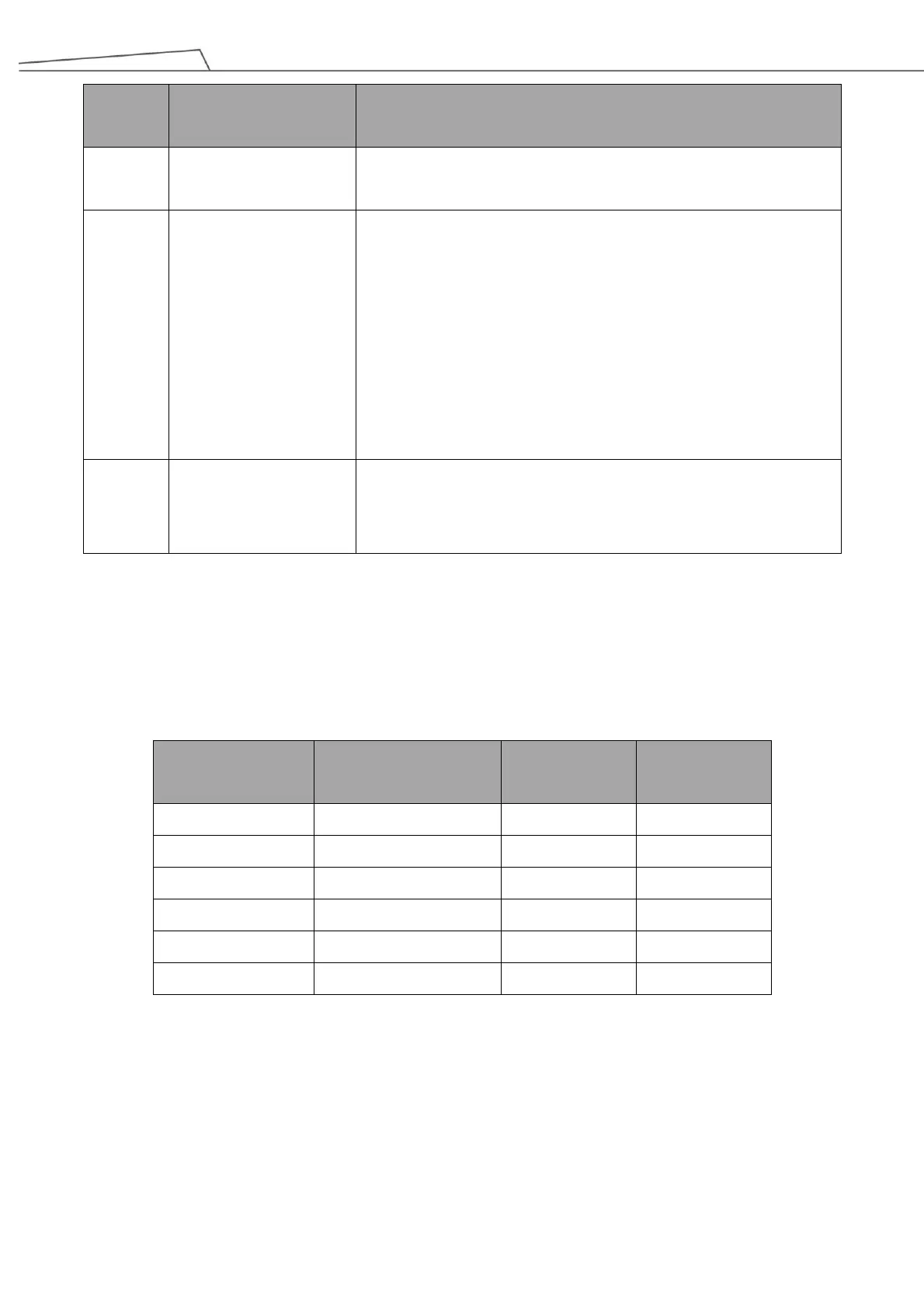

Refer to the table below for the stop category and the action of fault detection for the safety functions.

When any fault other than discrepancy detected in the safety functions, the system performs a Cat. 0 stop.

When Cat. 0 stop occurs, reboot the robot system to recover from Cat.0 stop status.

Reaction of

Fault Detection

Table 14: Stop Category and Action of Fault Detection of SF10~ SF15

Refer to the relevant contents in TMflow Software Manual for the detailed setting of each item.

Regarding methods to recover the robot system from protective stop manually from SF10 – SF15, refer to

the relevant sections in Safety Manual (Techman Robot Safety System 3.2).

Loading...

Loading...