5-18

Fuel control unit and component

0

1

2

3

4

5

6

7

8

9

10

A

6. Connect the fuel injector couplers.

Checking the high-pressure fuel

pump

1. Check the operation of the high-pressure

fuel pump using the YDIS “Stationary

test” and check the operating sound.

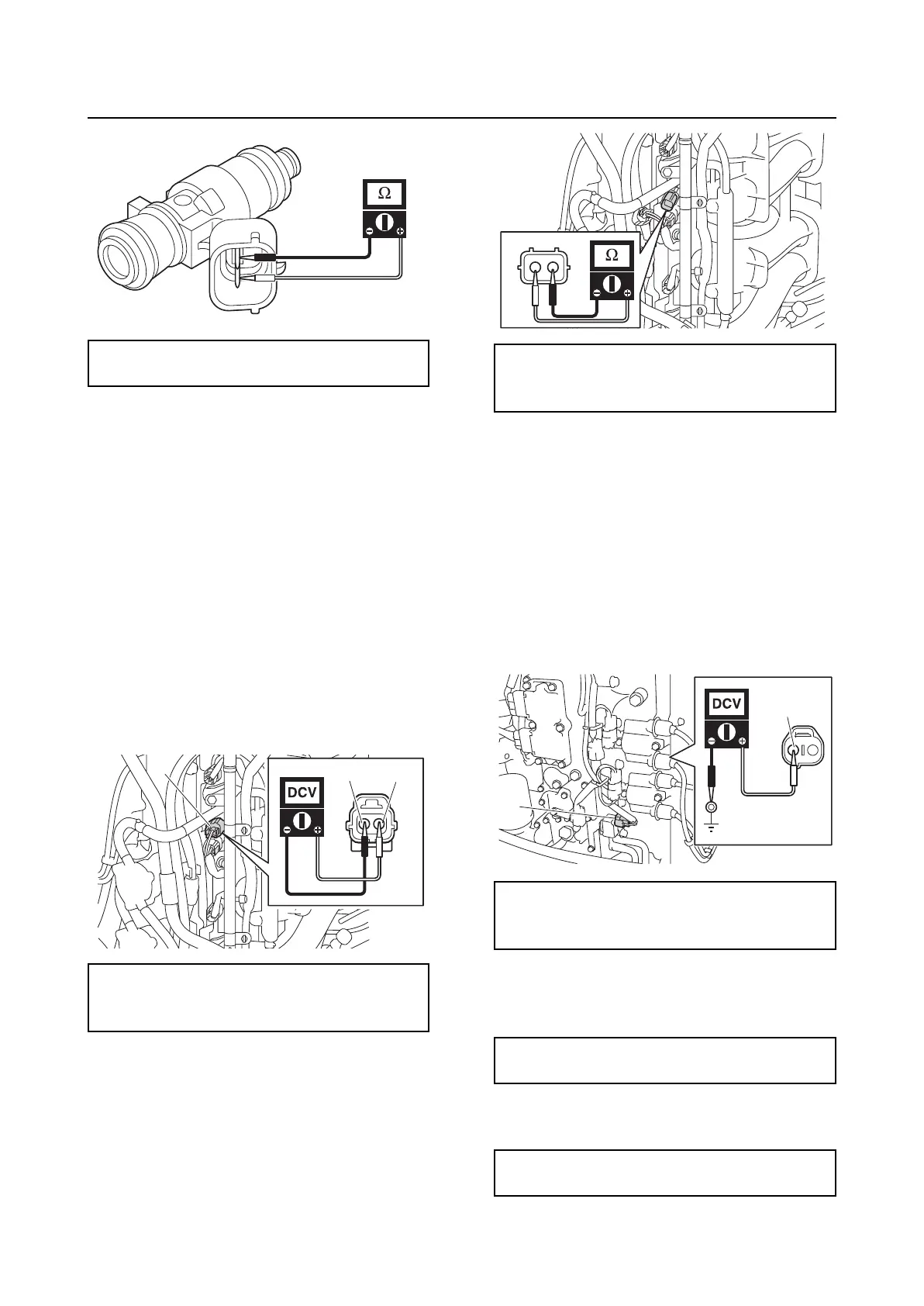

2. Disconnect the high-pressure fuel pump

coupler “a”.

3. Connect the tester probes to the termi-

nals of the high-pressure fuel pump cou-

pler, and then measure the input voltage

within 3 seconds after turning the engine

start switch to ON.

4. Turn the engine start switch to OFF.

5. Measure the high-pressure fuel pump

motor resistance.

6. Connect the high-pressure fuel pump

coupler.

Checking the vapor shut-off valve

1. Disconnect the vapor shut-off valve cou-

pler “a”.

2. Turn the engine start switch to ON, and

then measure the input voltage between

the vapor shut-off valve coupler terminal

and ground.

3. Remove the vapor shut-off valve, and

then connect the special service tool “1”

to the vapor shut-off valve.

4. Apply the specified negative pressure to

the vapor shut-off valve.

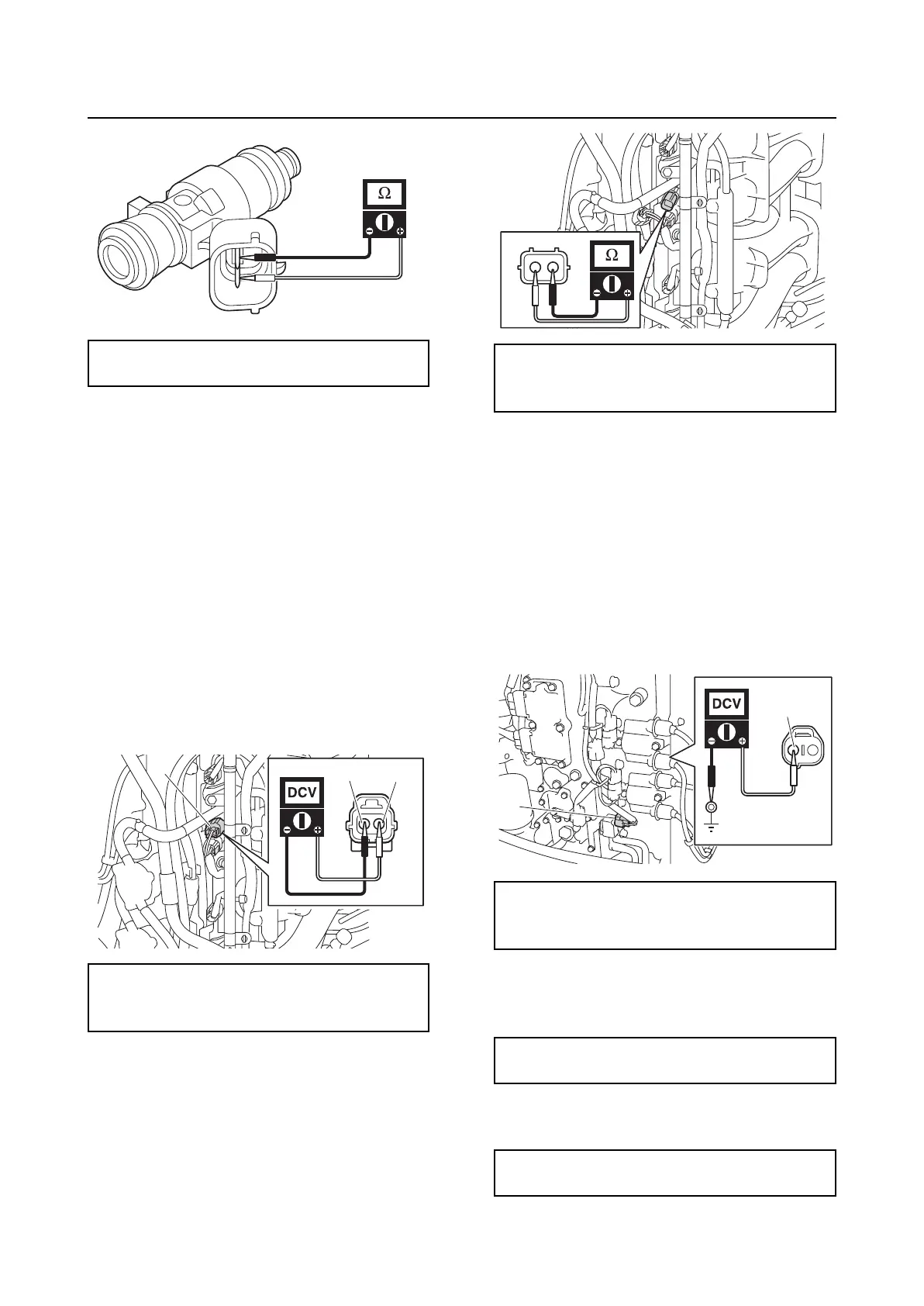

Fuel injector resistance (reference data):

11.50–12.50 Ω at 20 °C (68 °F)

High-pressure fuel pump input voltage:

Red/Yellow (R/Y)–Blue (L)

12 V (battery voltage)

L

R/Y

a

High-pressure fuel pump resistance

(reference data):

0.5–10.0 Ω

Vapor shut-off valve input voltage:

Red/Yellow (R/Y)–Ground

12 V (battery voltage)

Vacuum/pressure pump gauge set “1”:

90890-06945

Specified negative pressure:

67.0 kPa (0.67 kgf/cm

2

, 9.7 psi)

a

R/Y

Loading...

Loading...