7-65

Crankcase

0

1

2

3

4

5

6

7

8

9

10

A

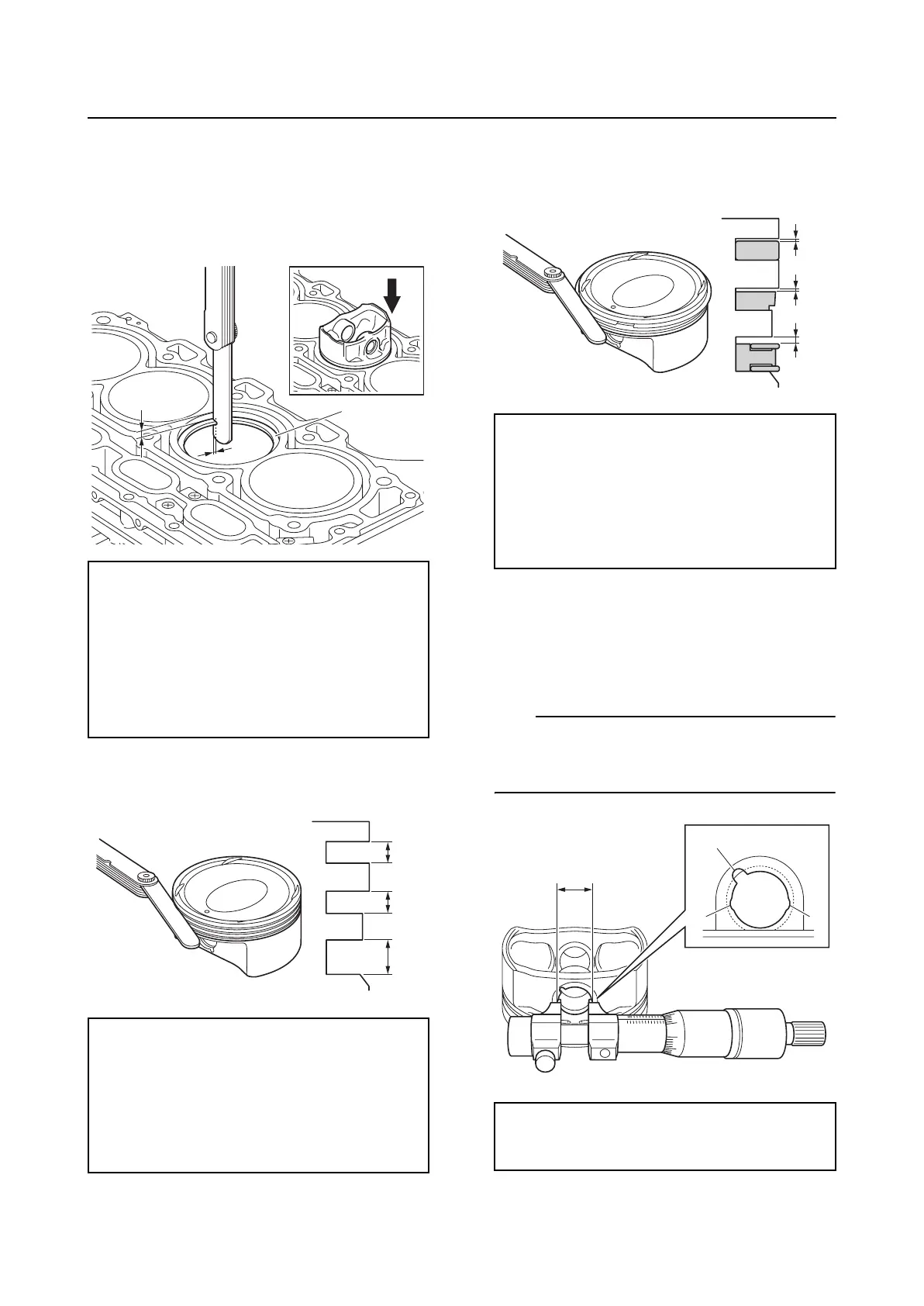

Checking the piston ring end gap

1. Level the piston ring “1” in the cylinder

using a piston crown at the specified

measuring point “a”.

2. Measure the piston ring end gap “b”.

Checking the piston ring groove

1. Measure the piston ring grooves.

Checking the piston ring side

clearance

1. Measure the piston ring side clearance.

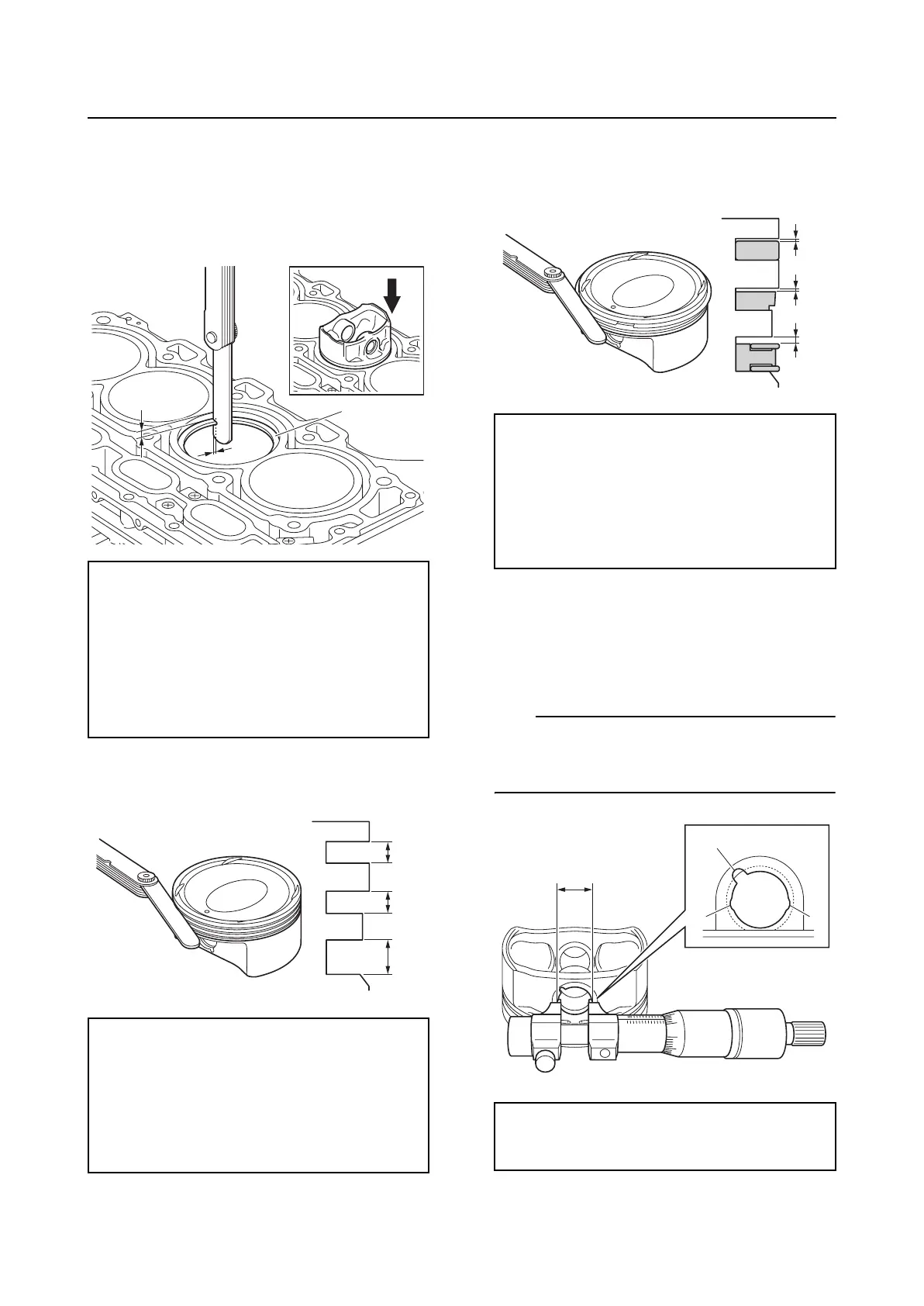

Checking the piston pin boss inside

diameter

1. Measure the piston pin boss inside diam-

eter “a”.

TIP:

When measuring the piston pin boss inside

diameter, do not measure it at the ring groove

“b” or oil groove “c”.

Measuring point “a”: 10.0 mm (0.39 in)

Piston ring end gap “b” (reference data):

Top ring:

0.20–0.30 mm (0.0079–0.0118 in)

2nd ring:

0.30–0.45 mm (0.0118–0.0177 in)

Oil ring:

0.15–0.60 mm (0.0059–0.0236 in)

Piston ring groove:

Top ring “a”:

1.23–1.25 mm (0.0484–0.0492 in)

2nd ring “b”:

1.22–1.24 mm (0.0480–0.0488 in)

Oil ring “c”:

2.51–2.53 mm (0.0988–0.0996 in)

a

b

1

a

b

c

Piston ring side clearance:

Top ring “a”:

0.04–0.08 mm (0.0016–0.0031 in)

2nd ring “b”:

0.03–0.07 mm (0.0012–0.0028 in)

Oil ring “c”:

0.04–0.13 mm (0.0016–0.0051 in)

Piston pin boss inside diameter “a”:

21.021–21.031 mm

(0.8276–0.8280 in)

a

b

c

a

b

c

c

Loading...

Loading...