8-39

Shimming (regular rotation model)

Selecting the pinion shim (T3)

• Spray anti-rust lubricant on the bearing

before installation. Do not apply gear oil to

the parts. Otherwise, correct measure-

ments cannot be obtained.

• Keep the parts free of foreign material,

such as dirt and lint.

Be careful not to damage the measure-

ment plane surface of the special service

tool. Otherwise, correct measurements

cannot be obtained.

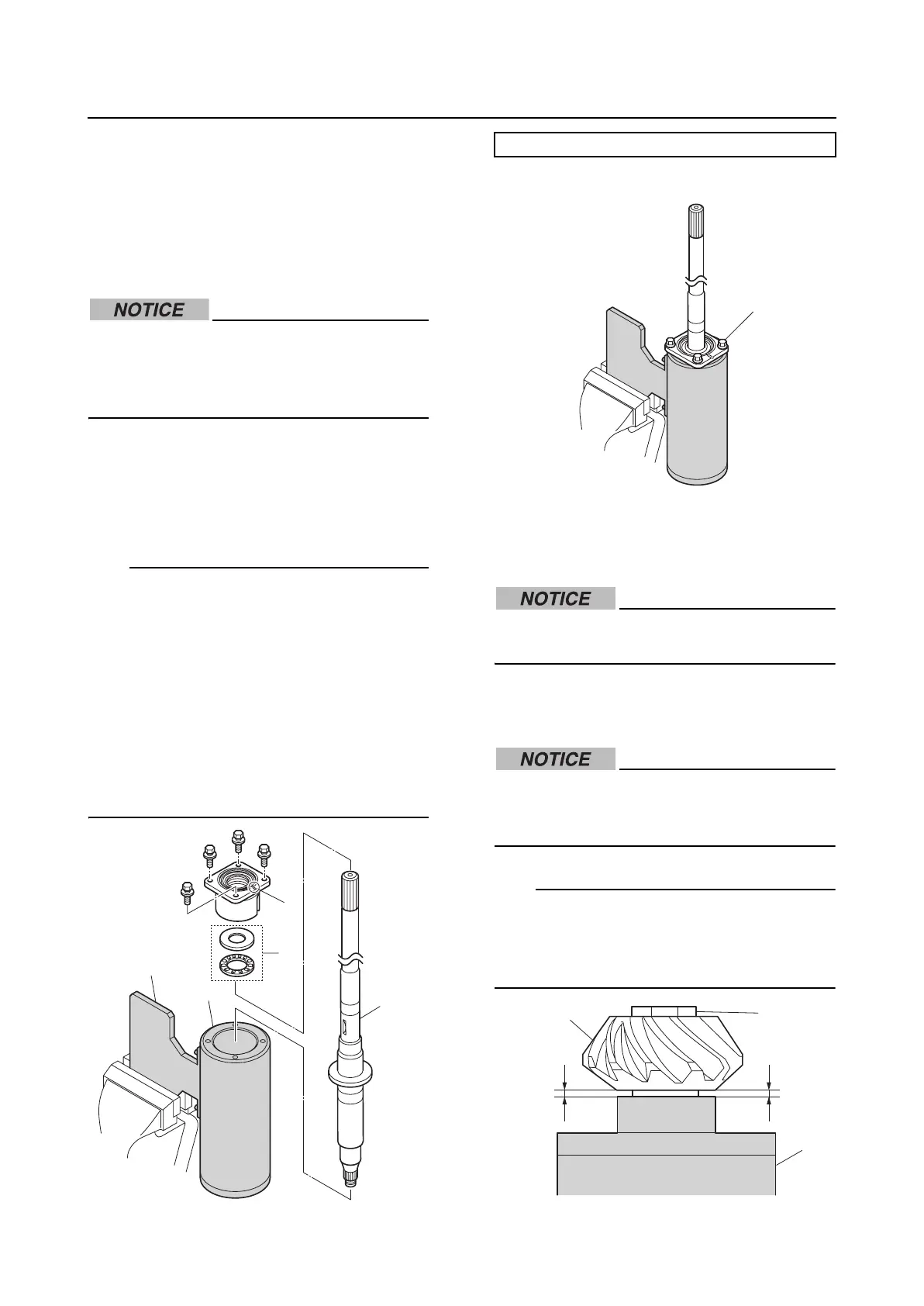

1. Hold the special service tool “1”, and

then install the drive shaft “2”, thrust

bearing “3”, and drive shaft housing

assembly to the special service tool.

TIP:

• Do not install the pinion shims (T3) and

O-ring. Make sure that the pinion shims

(T3) are not affixed to the thrust bearing

outer race.

• Make sure to install the thrust bearing outer

race so that it is facing the same direction

as when it was removed.

• Make sure that the cutout “a” in the drive

shaft housing assembly is facing the oppo-

site direction of the plate “4” of the special

service tool.

2. Tighten the drive shaft housing bolts “1”.

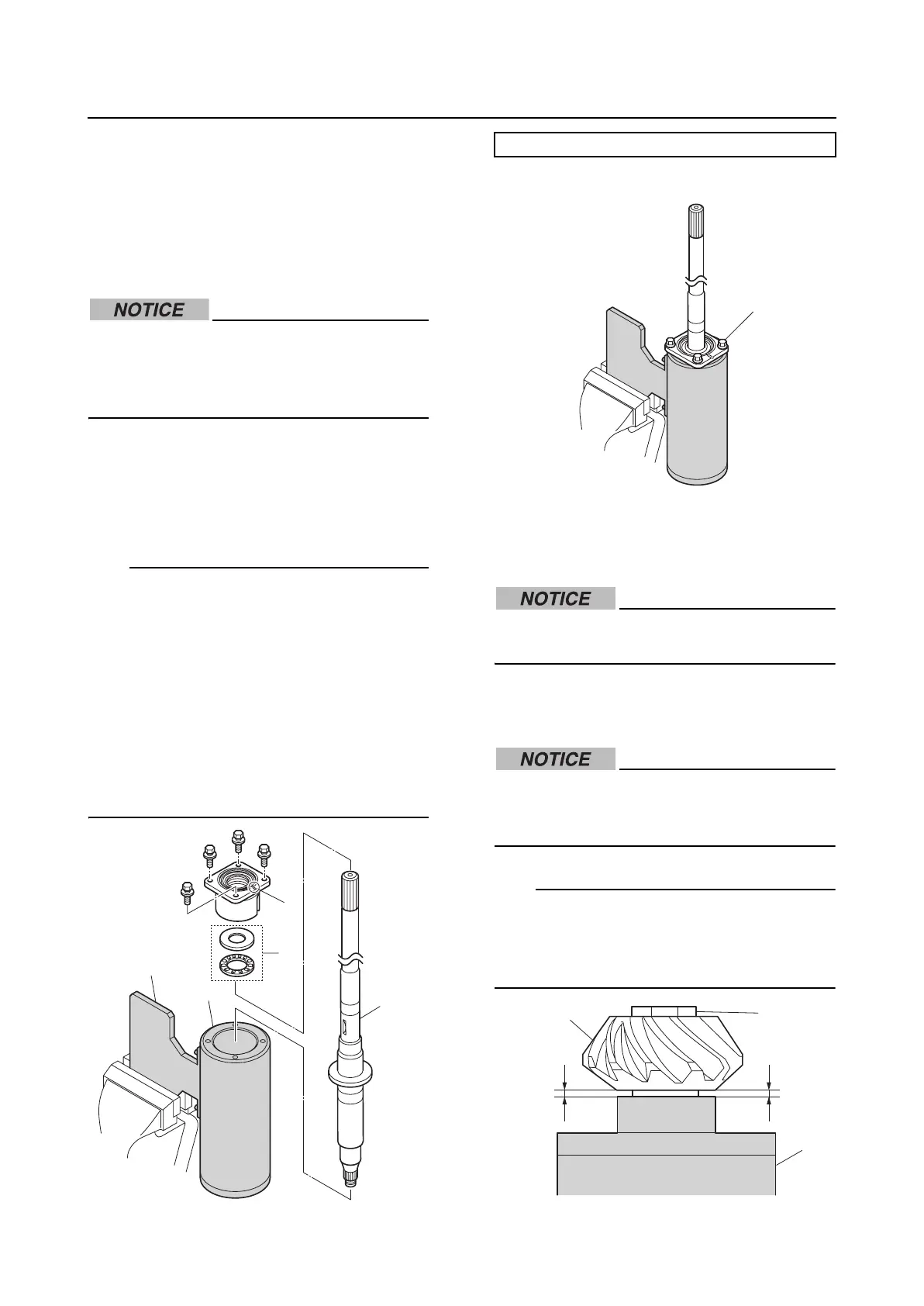

3. Install the pinion “1” and pinion nut “2”,

and then tighten the pinion nut “2”

temporarily.

When tightening the pinion nut, check

that the drive shaft turns smoothly.

4. Check that there is a gap “a” between the

pinion “1” and the special service tool “3”.

If there is no gap and the drive shaft does

not turn, the special service tool could be

damaged.

TIP:

If there is no gap, the thrust bearing outer

race “4” may not have been installed. If the

gap is 1.0 mm (0.039 in) or more, the pinion

shims (T3) “5” may not have been removed.

1

2

3

a

4

Pinion height gauge “1”: 90890-06671

1

1

2

3

aa

Loading...

Loading...