197

M4.3-1055-500

ELECTRICAL

Control Modules

Control Modules

Traction Drive Module

Basics of System Operation

The AC traction drive module (Access 3) applies a vari-

able frequency current and pulse width modulated

three phase AC voltage to the motor stator to generate

a rotating magnetic field. The rotating magnetic field

induces an opposing magnetic field in the rotor which

causes the rotor to turn. Using this technology elimi-

nates the need for motor brushes as well as forward

and reversing contactors and the associated mainte-

nance. The traction drive module contains the power

circuitry for converting the DC input to three phase AC

output and controls the Pulse Width Modulation (PWM)

of the voltage and the frequency of the resultant current

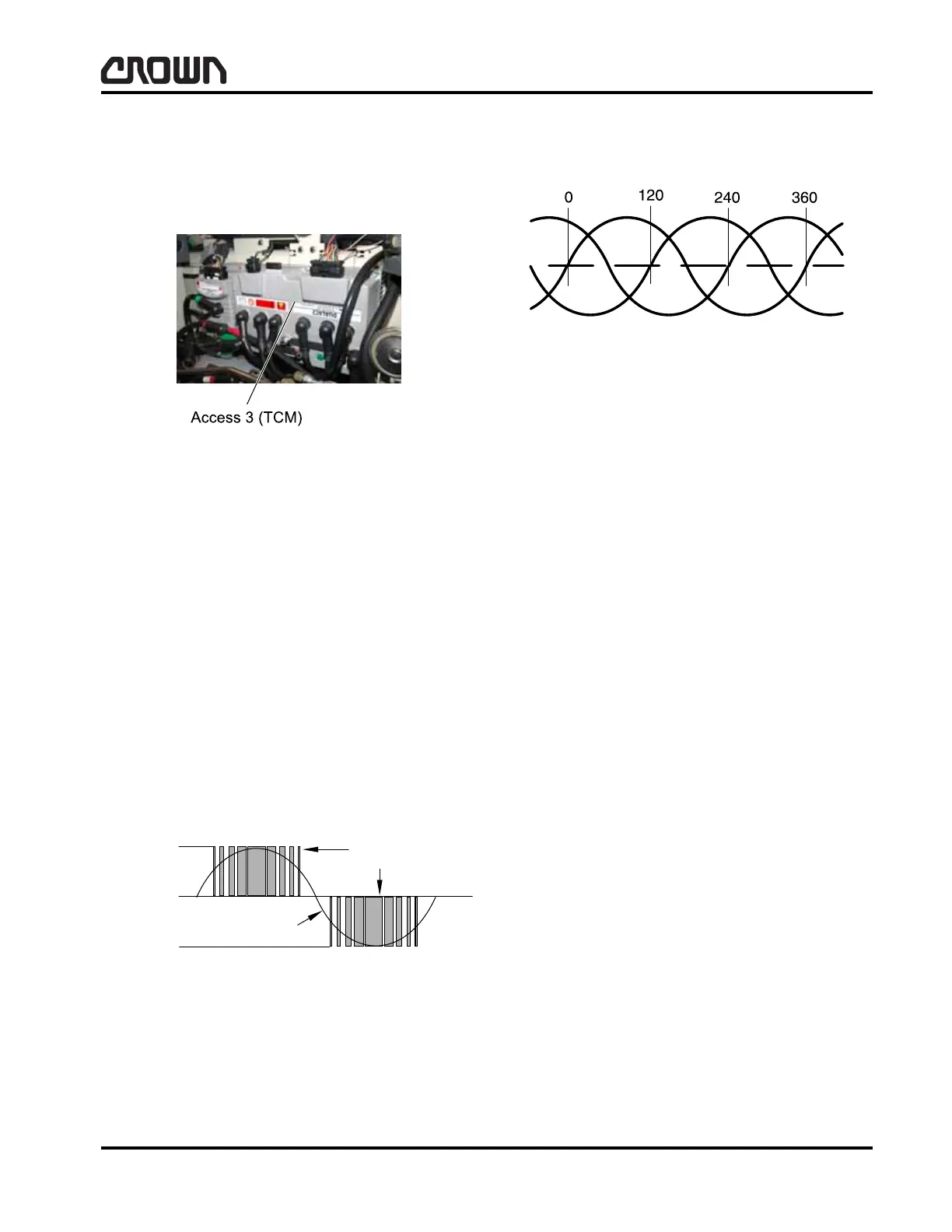

waveform. The resulting output is shown (single phase

shown).

Each phase of the output is 120 degrees out of phase

as shown.

Each phase is applied to separate windings in the

motor stator, resulting in the rotating magnetic field

which causes rotation of the rotor. Access 3 manages

the speed regulation and various system inputs and

outputs.

Inherent to the design of AC motors is generated volt-

age when using motor braking. Without the need for

additional contactors or resistance, this voltage is

applied to the battery to extend the usable charge

available.

Motor torque is variable making closed loop speed reg-

ulation possible. This will maintain vehicle speed,

within the limits of the motor and drive system, as

determined by the speed request. A speed sensor

bearing in the motor provides the feedback signal to

the traction drive module for control of the AC power

converter. Speed feedback is also provided to Access

3 for speed regulation.

Control Circuit Operation

The control circuitry of the Access 3 module is software

driven with the parameters set for the system by the

Features and Performance menus.

Figure 15950

Figure 9892-01

Positive

Battery

Volts

Negative

Battery

Volts

Current

Waveform

Voltage

Modulation

Figure 9893

Crown 2007 PF15712-1

Loading...

Loading...