121

Dosing process is carried out manually and automatically, and it incudes a

condition that the dosing sequence is strictly determined – dosing of “Water”

ingredient can be initiated only on completing the dosing process of ingredient

“Flour” and “Sugar”. Ingredient “Seasoning” will be added as the last one to the

dosing process.

The condition is marked with signal flags, which determine formulation making

process between the weighing platforms, in a way which orders dosing “Water”

ingredient is dosed in an appropriate time. The whole process is described

below in tables, separately for each weighing platform.

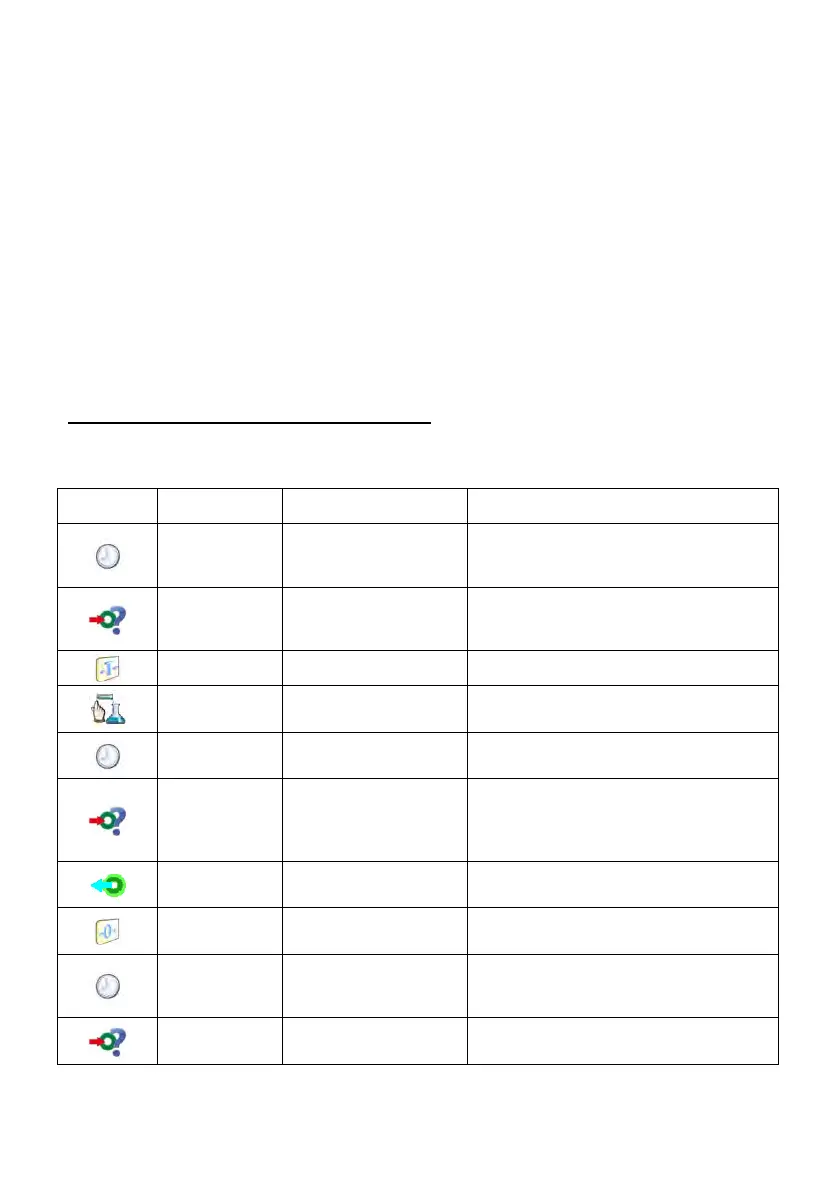

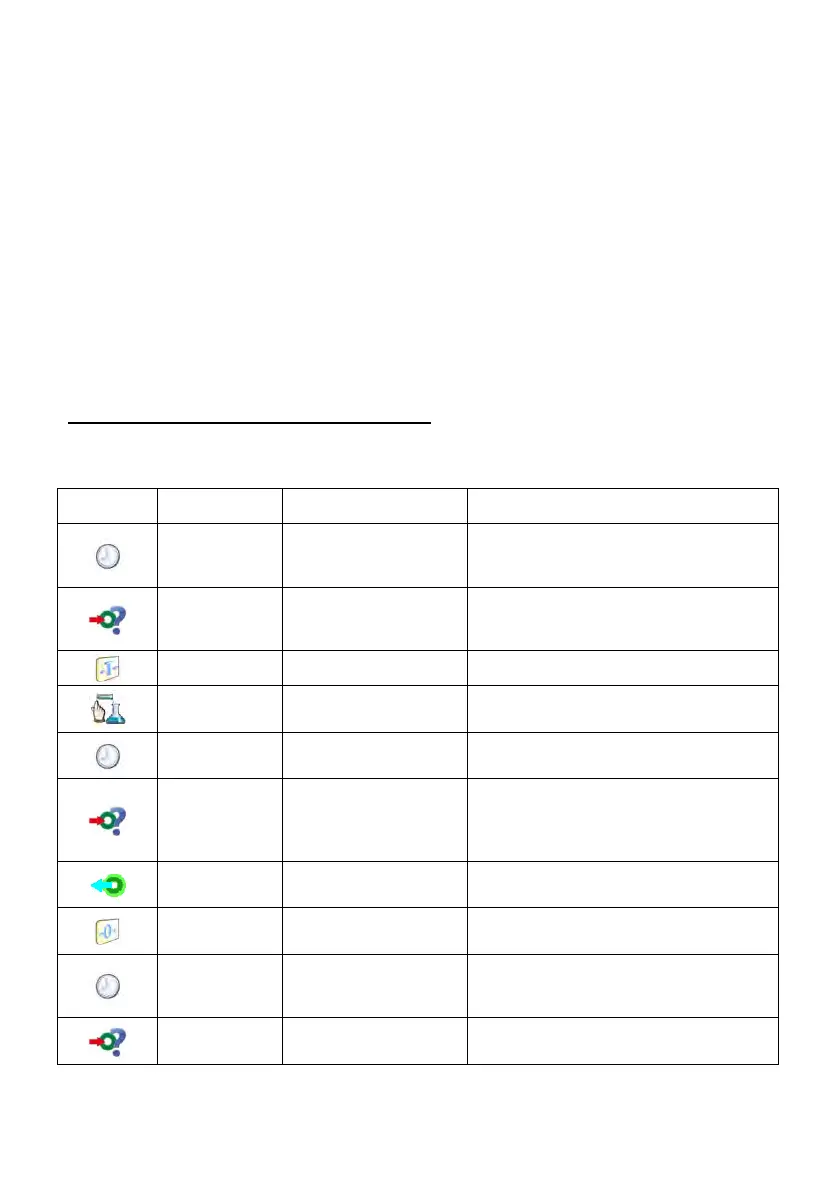

Dosing process name: Instance 3

Dosing process code: 3333

Dosing process from a indicator level:

Platform 1:

Icon Step Value Description

1. [TI] Delay

[5s] Place container

Flour on the weighing

platform

Pending for loading container “Flour” on

the weighing platform no. 1

2. [CI] Input

condition

Input 1 – „/”

Input 1 has to take increasing tendency

– press function key confirming loading

a container

3. [T] Tare Tare Tarring the weighing platform no. 1

4. [DH] Dose

manually

1 kg [Flour]

Manual weighing product Flour to obtain

1 kg mass

5. [TI] Delay

[7s] Unload container

with product

Pending for unloading the container with

“Flour”

6. [CI] Input

condition

Input 4 – „/”

Input 4 has to take increasing tendency

– press function key confirming

unloading a container from the weighing

platform

7. [O] Outputs Output 1 – „1”

Signal on completing dosing ingredient

“Flour”

8. [Z] Zero Zero Zeroing the weighing platform no. 1

9. [TI] Delay

[5s] Place container

Sugar on the weighing

platform

Pending for loading container “Sugar” on

the weighing platform no. 1

10. [CI] Input

condition

Input 1 – „/” Confirm loading of container “Sugar”

Loading...

Loading...