5.24

SEL-2414 Transformer Monitor Instruction Manual Date Code 20130214

Metering and Monitoring

Monitoring

Cooling Stage Activation (TxCSy)

Range: SELOGIC control equation

The thermal element uses the output of SEL

OGIC control equations to determine

which cooling stage is active, so that thermal element calculations use the correct

transformer constants. The settings ETHERM and NUMCS determine the

number of SEL

OGIC control equations the relay will prompt the user for.

The TxCSy SEL

OGIC control equations can be set to any of the Device Word bits

except Row 0 and Row 1 of Table 4.9. However, it is critical that they be

configured to accurately indicate which cooling system is active. In the simplest

implementation, this will consist of one or two external contacts from the

monitored power transformer connected to optoisolated inputs on the SEL-2414

with the CsxyS SEL

OGIC control equations set to the corresponding digital input.

See Cooling Stage Determination on page 5.15 for more information.

Default Ambient Temperature (D_AMB)

Range: –50° to 100°C, in 1°C steps

Select a reasonable value for D_AMB, in degrees Celcius to be used as the

ambient temperature in case the measured ambient measurement fails. The

ambient measurement will be used if MAMB_OK deasserts. See setting

description for AMB_F for more information.

Transformer De-Energized (TRDE)

Range: SELOGIC control equation

Transformer heating consists of heating resulting from transformer no load losses

and heating resulting from load losses. IEEE standard C57.91-1995 assumes the

transformer is energized and calculates an increase in oil and winding hot-spot

temperatures resulting from transformer no-load losses. Device Word bit TRDE

provides the thermal element a way to distinguish between the de-energized and

energized stages. For example, wire a 52b (normally closed) circuit breaker

auxiliary contact to input IN101 and enter the SEL

OGIC control equation TRDE =

IN101. When IN101 asserts (circuit breaker main contacts open and the 52b

auxiliary contacts closed), the thermal element considers the transformer de-

energized and the ambient, top-oil, and hot-spot temperatures will equalize to all

have the same temperature, given enough time.

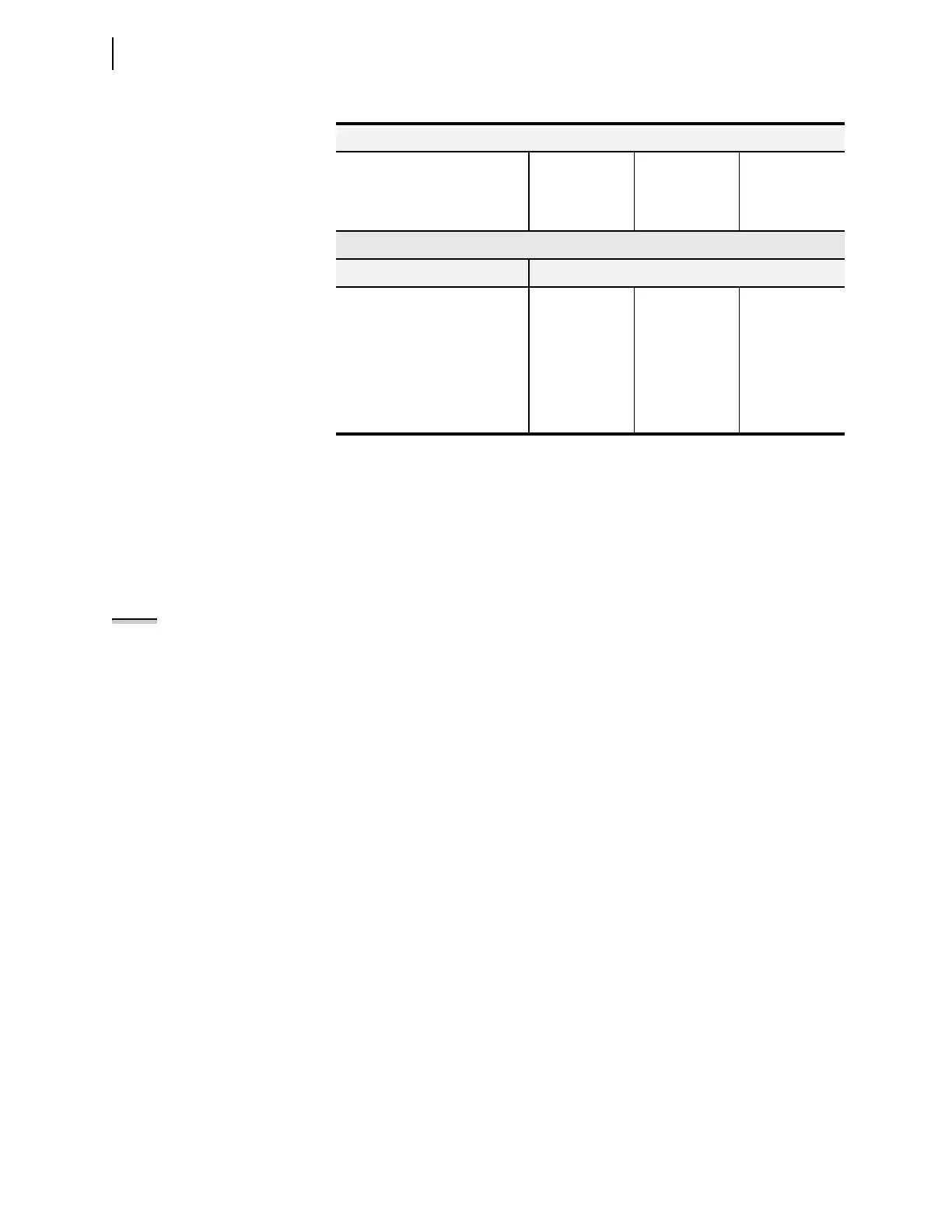

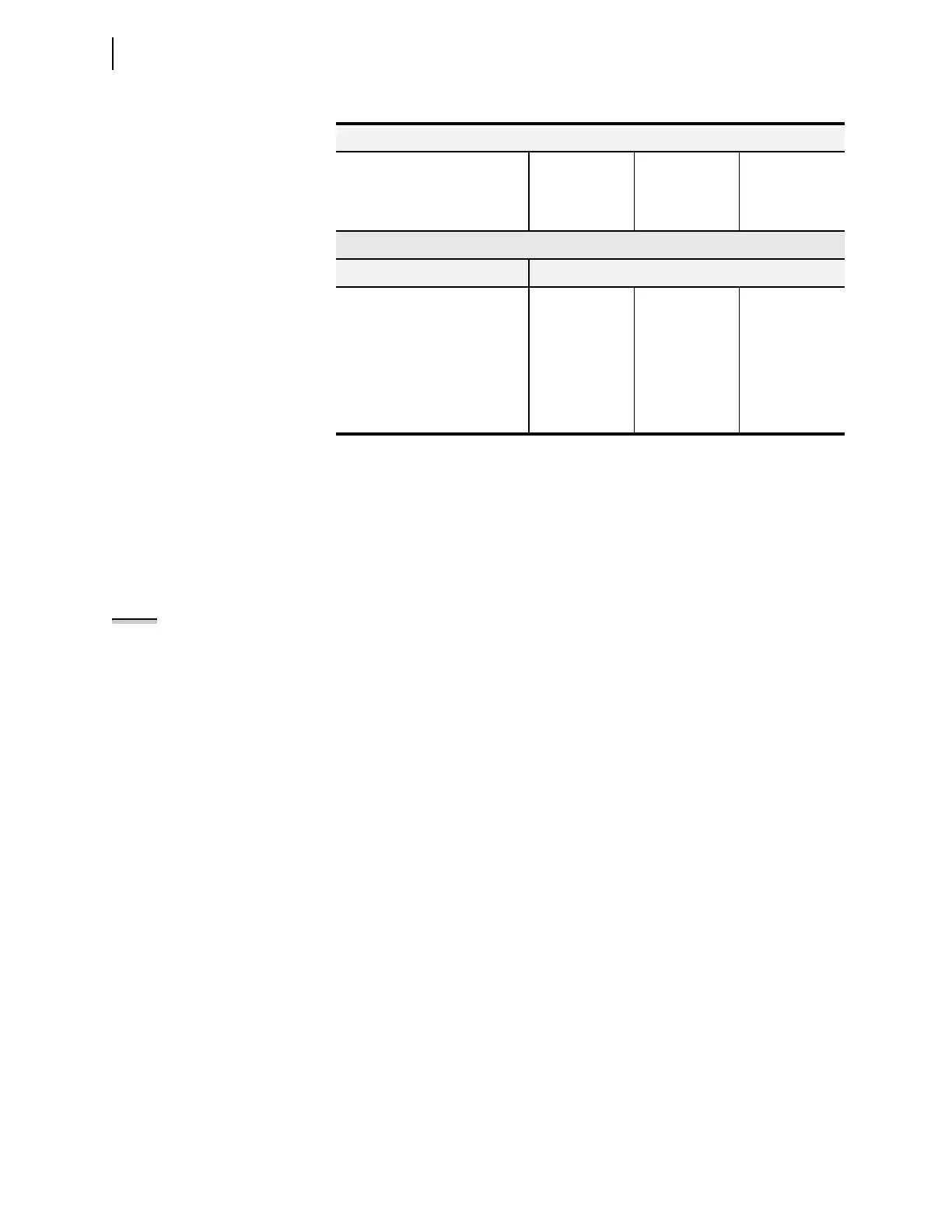

CS2

(forced air cooled ONAF)

MVA1CS2 = 140 MVA2CS2 = 140 MVA3CS2 = 140

CS3

(forced-oil and air cooled OFAF)

MVA1CS3 = 170 MVA2CS3 = 170 MVA3CS3 = 170

ETHERM = W

Cooling System MVA Rating

Winding 1 Winding 2 Winding 3

CS1

(natural oil and air cooled ONAN)

MVA1CS1 = 100 MVA2CS1 = 100 MVA3CS1 = 10

CS2

(forced air cooled ONAF)

MVA1CS2 = 140 MVA2CS2 = 140 MVA3CS2 = 14

CS3

(forced-oil and air cooled OFAF)

MVA1CS3 = 170 MVA2CS3 = 170 MVA3CS3 = 17

Table 5.13 Examples of Cooling Stages and MVA Ratings

ETHERM = 1

NOTE: x designates the transformer

and y designates the cooling stage.

Loading...

Loading...