43.SPEED SENSOR

44.SIDE STAND SWITCH

45.GEAR SENSOR

46.FRONT CYLINDERS PRESSURE SENSOR

47.REAR CYLINDERS PRESSURE SENSOR

48.FRONT CYLINDERS THROTTLE VALVES

49.REAR CYLINDER THROTTLE VALVES

50.AIR TEMPERATURE SENSOR

51.WATER TEMPERATURE SENSOR

52.TOP INJECTORS

53.75M CONTROL UNIT

54.EFG 1X THROTTLE CONTROL UNIT

55.REVOLUTION SENSOR

56.COIL

57.SPARK PLUG

58.BOTTOM INJECTORS

59.SECONDARY AIR

60.LAMBDA PROBE

61.VARIABLE GEOMETRY ECU (OPTIONAL)

62.VARIABLE GEOMETRY ENGINE (OPTIONAL)

Checks and inspections

GENERAL CONCEPTS OF ELECTRICAL TROUBLESHOOTING

THE CONNECTION DIAGRAMS ARE IN THE ELECTRICAL SYSTEM SECTIONS; PAY ATTENTION

TO THESE DIAGRAMS AS THEY SHOW THE CONNECTOR/COMPONENT AS VIEWED FROM

THE CABLE HARNESS SIDE, THAT IS LOOKING AT THE CABLES WHEN GOING OUT OF THE

"MAIN" CABLE HARNESS AND INTO THE CONNECTOR/COMPONENT.

CAUTION

BEFORE CARRYING OUT ANY TROUBLESHOOTING PROCEDURE ON THE VEHICLE, CHECK

THAT THE BATTERY VOLTAGE IS ABOVE 12V.

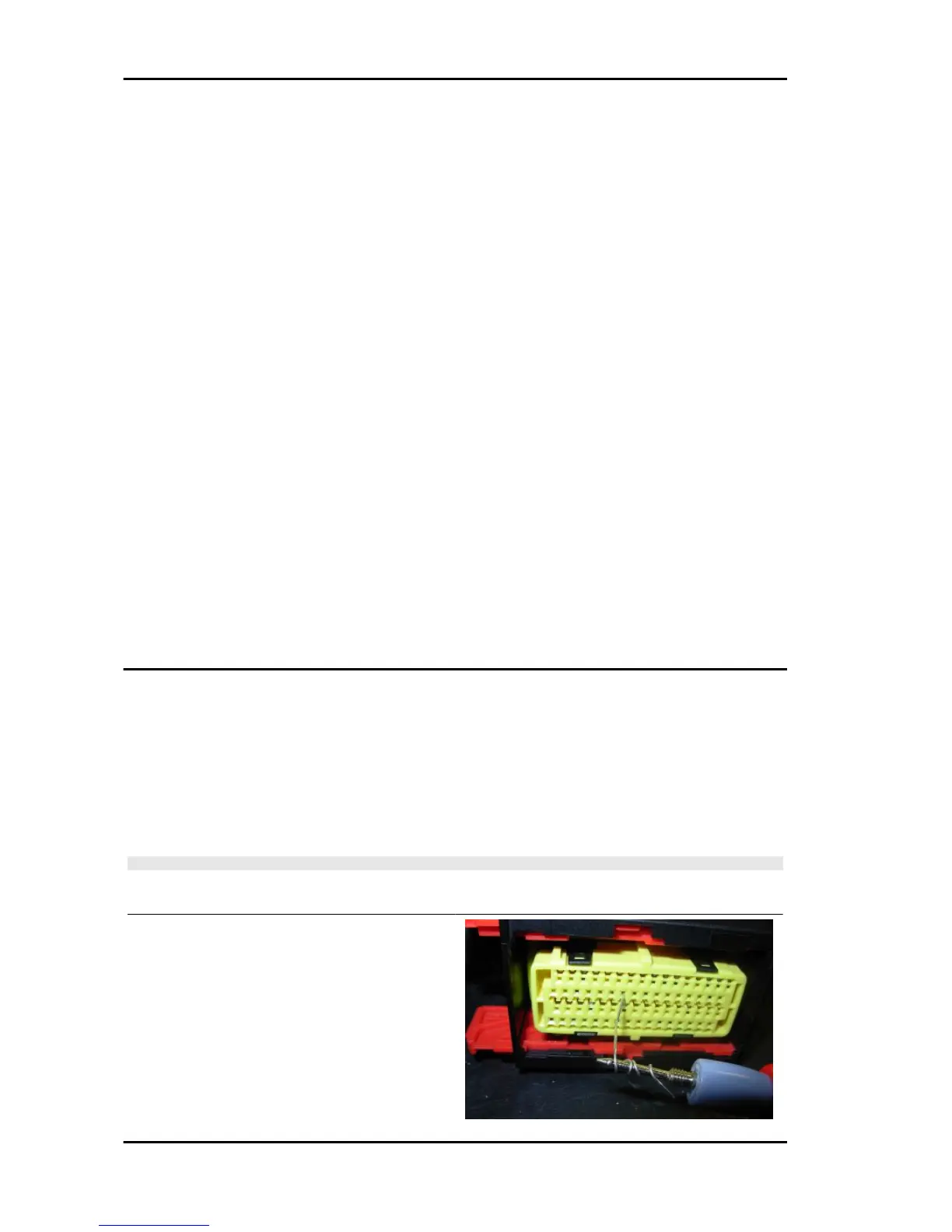

CONNECTOR CHECK PROCEDURE

The procedure includes the following checks:

1. Observation and check of the connector position

on the component or on the coupling connector,

making sure that the locking catch is released.

2. Observation of the terminals on the connector:

no rust marks or dirt should be present and it is

important to check terminal correct positioning on

Electrical system RSV4 R

ELE SYS - 134

Loading...

Loading...