PID Loop Operation

Maintenance

and Troubleshooting

8–2

PID Loop Operation

DL05 PID Loop Features

The DL05 process loop control offers a sophisticated set of features to address

many application needs. The main features are:

S Up to 4 loops, individual programmable sample rates

S Manual/ Automatic/Cascaded loop capability available

S Two types of bumpless transfer available

S Full-featured alarms

S Ramp/soak generator with up to 16 segments

S Auto Tuning

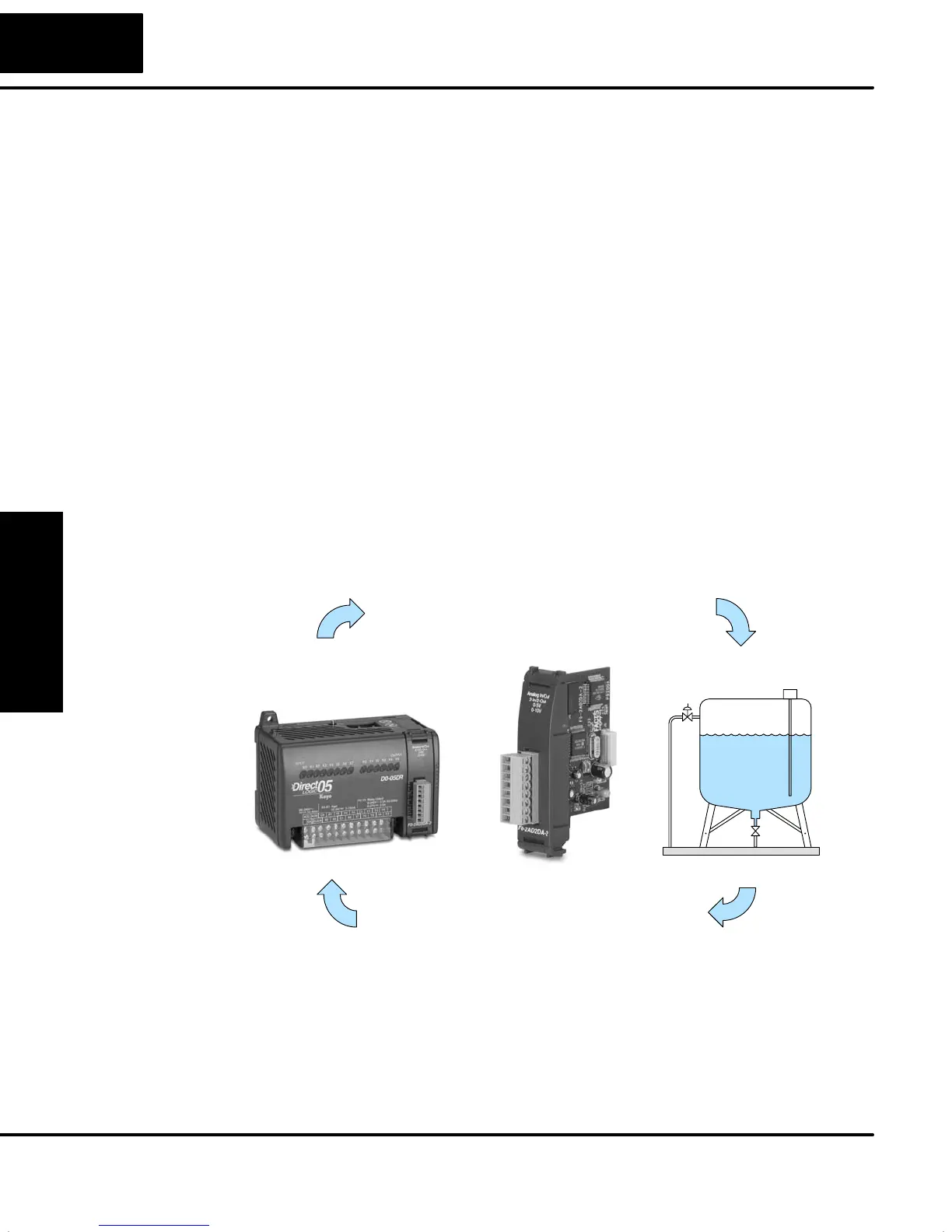

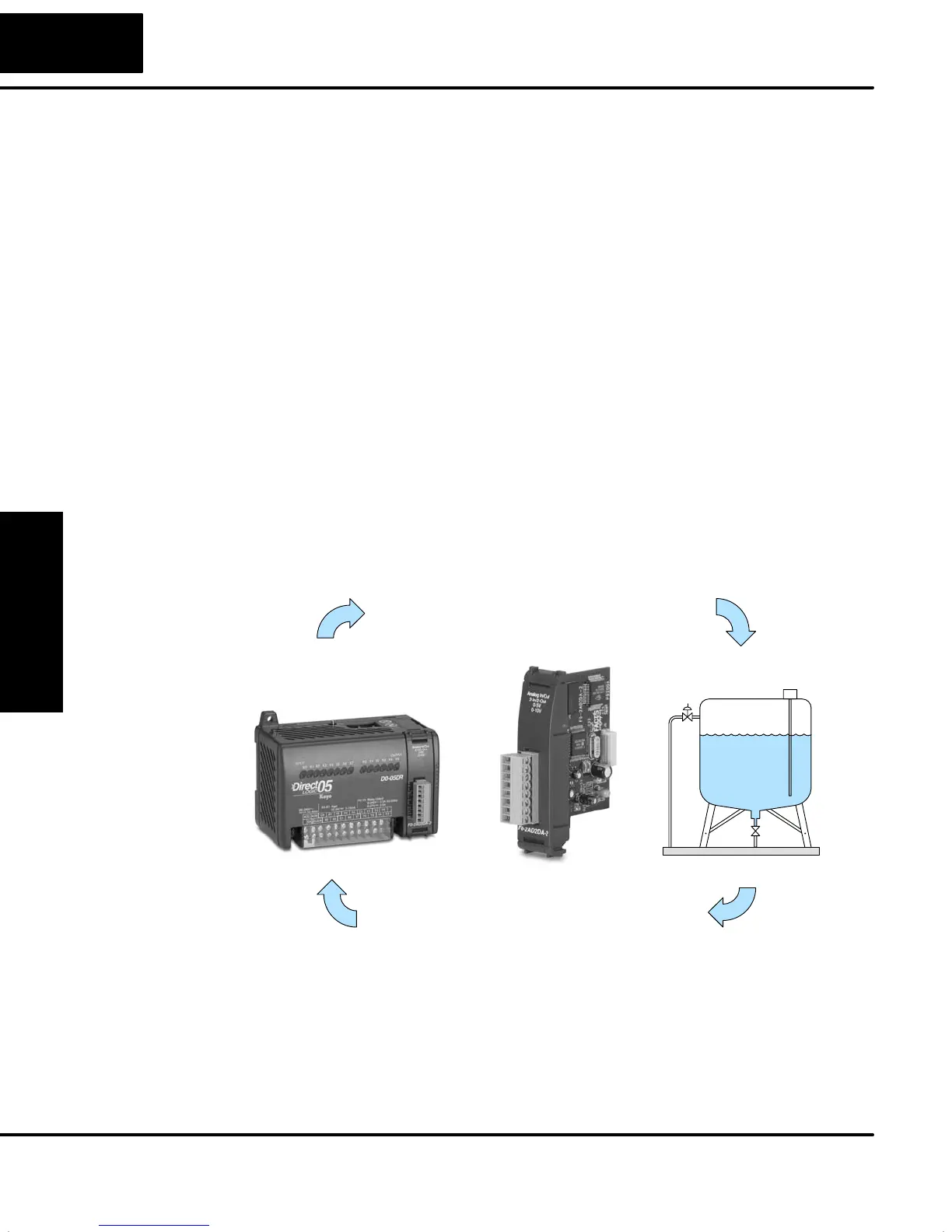

The DL05 CPU has process control loop capability in addition to ladder program

execution. You can select and configure up to four loops. All sensor and actuator

wiring connects directly to DL05 analog modules. All process variables, gain values,

alarm levels, etc., associated with each loop reside in a Loop Variable Table in the

CPU. The DL05 CPU reads process variable (PV) inputs during each scan. Then it

makes PID loop calculations during a dedicated time slice on each PLC scan,

updating the control output value. The control loops use a

Proportional-Integral-Derivative (PID) algorithm to generate the control output. This

chapter describes how the loops operate, and what you must do to configure and

tune the loops.

DL05

Manufacturing Process

PID Loop Calculations

Analog Output

Analog Input

The best tool for configuring loops in the DL05 is the DirectSOFT32 programming

software, release 3.0c, or later. DirectSOFT32 uses dialog boxes to help you set up

the individual loops. After completing the setup, you can use DirectSOFT32’s PID

Trend View to tune each loop. The configuration and tuning selections you make are

stored in the DL05’s FLASH memory, which is retentive. The loop parameters also

may be saved to disk for recall later.

Main Features

Loading...

Loading...