PID Loop Operation

Maintenance

and Troubleshooting

8–54

PID Loop Operation

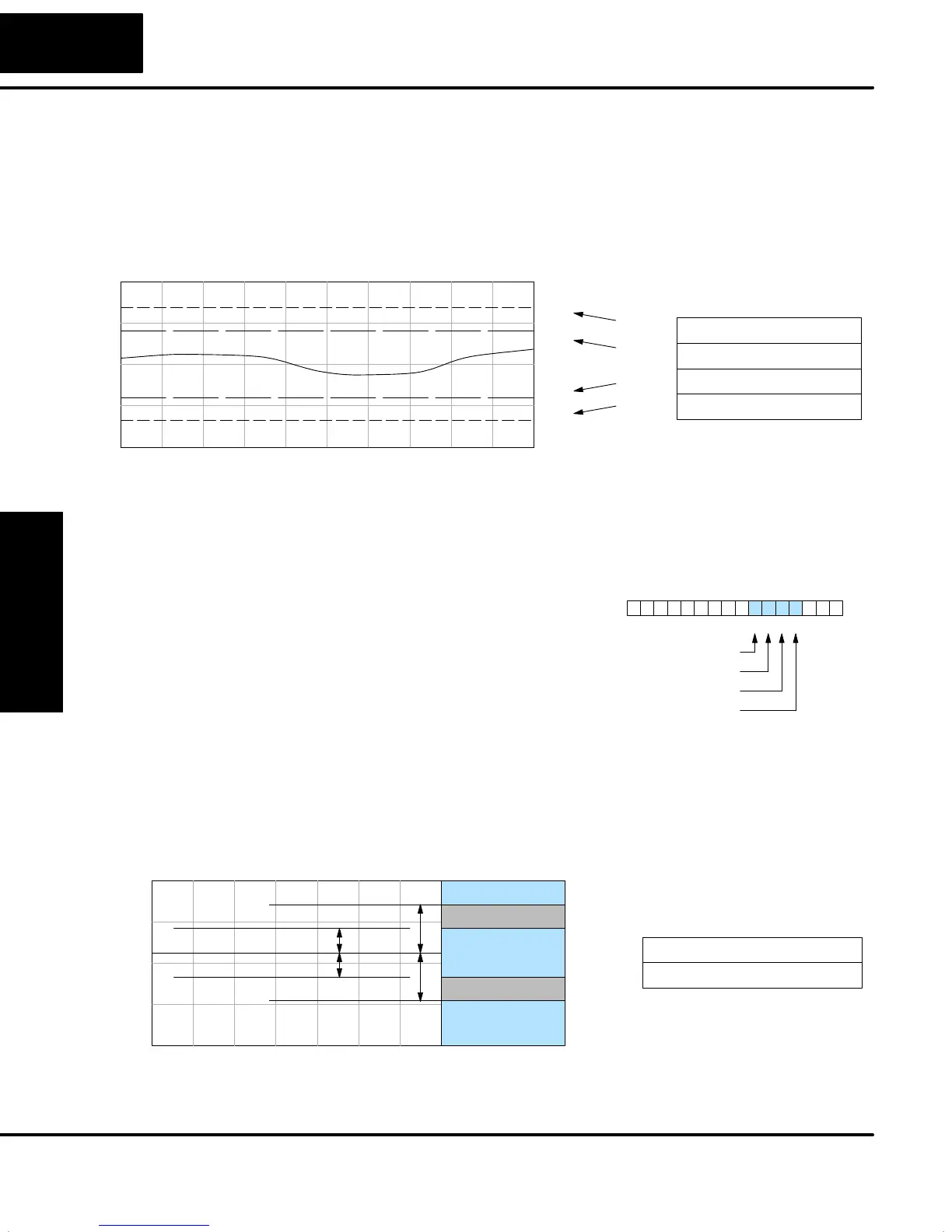

The PV absolute value alarms are organized as two upper and two lower alarms.

The alarm status is false as long as the PV value remains in the region between the

upper and lower alarms, as shown below. The alarms nearest the safe zone are

named High Alarm and Low Alarm. If the loop loses control, the PV will cross one of

these thresholds first. Therefore, you can program the appropriate alarm threshold

values in the loop table locations shown below to the right. The data format is the

same as the PV and SP (12-bit or 15-bit). The threshold values for these alarms

should be set to give an operator an early warning if the process loses control.

PV

High–high Alarm

High Alarm

Low Alarm

Low–low Alarm

Loop Table

V+16 High-high AlarmXXXX

V+15 High AlarmXXXX

V+14 Low AlarmXXXX

V+13 Low-low AlarmXXXX

If the process remains out of control for some time, the PV will eventually cross one

of the outer alarm thresholds, named High-high alarm and Low-low alarm. Their

threshold values are programmed using the loop table registers listed above. A

High-high or Low-low alarm indicates a serious condition exists, and needs the

immediate attention of the operator.

The PV Absolute Value Alarms are

reported in the four bits in the PID Mode

and Alarm Status word in the loop table, as

shown to the right. We highly recommend

using ladder logic to monitor these bits.

The bit-of-word instructions make this

easy to do. Additionally, you can monitor

PID alarms using DirectSOFT.

PID Mode and Alarm Status V+06

013456789101112131415 2Bit

High-high Alarm

High Alarm

Low Alarm

Low-low Alarm

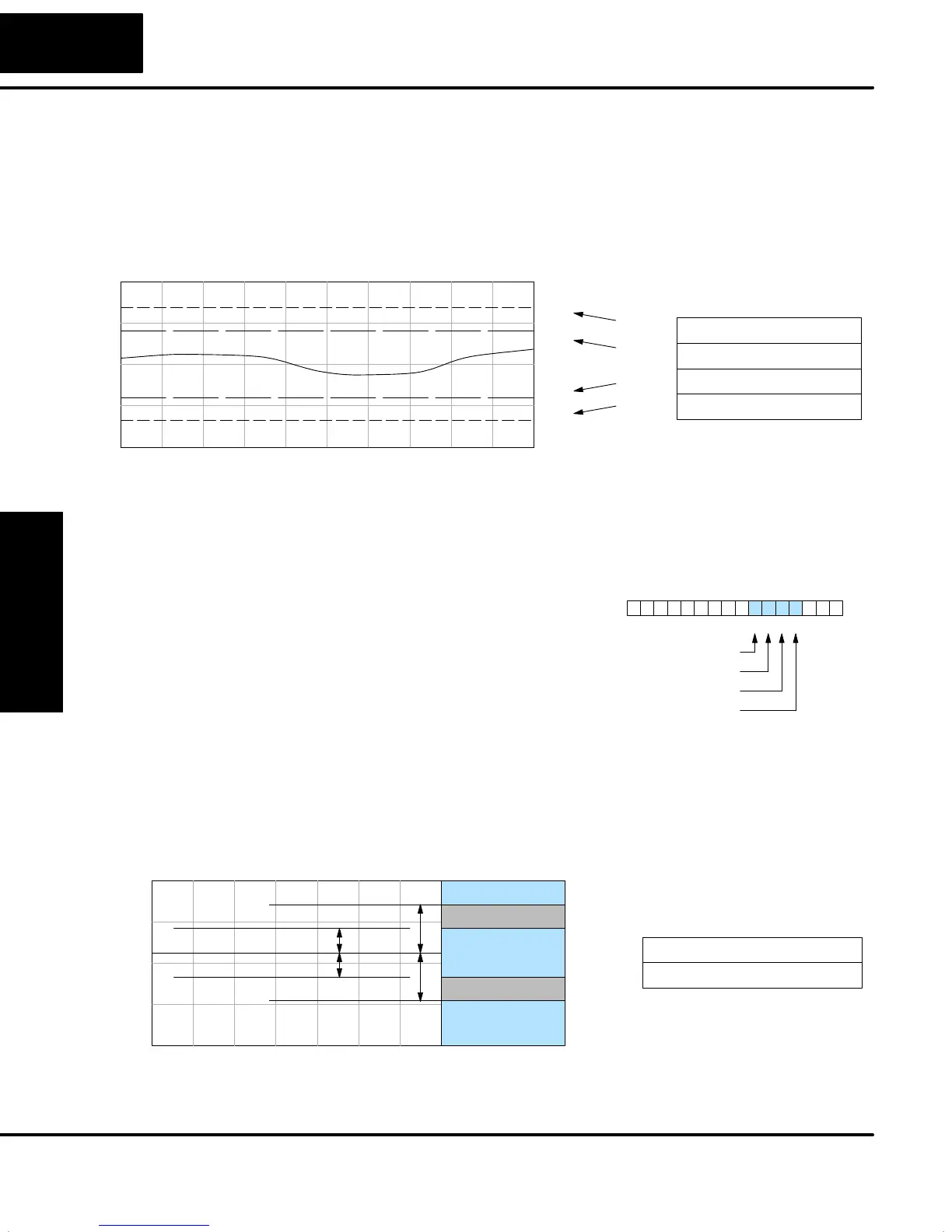

The PV Deviation Alarms monitor the PV deviation with respect to the SP value. The

deviation alarm has two programmable thresholds, and each threshold is applied

equally above and below the current SP value. In the figure below, the smaller

deviation alarm is called the “Yellow Deviation”, indicating a cautionary condition for

the loop. The larger deviation alarm is called the “Red Deviation”, indicating a strong

error condition for the loop. The threshold values use the loop parameter table

locations V+17 and V+20 as shown.

SP

Red Deviation Alarm

Yellow Deviation Alarm

Loop Table

V+17 Yellow Deviation AlarmXXXX

V+20 Red Deviation AlarmXXXX

Yellow Deviation Alarm

Red Deviation Alarm

Green

Yellow

Red

Yellow

Red

The thresholds define zones, which fluctuate with the SP value. The green zone

which surrounds the SP value represents a safe (no alarm) condition. The yellow

zones lie outside the green zone, and the red zones are beyond those.

PV Absolute

Value Alarms

PV Deviation

Alarms

Loading...

Loading...