PID Loop Operation

Maintenance

and Troubleshooting

8–28

PID Loop Operation

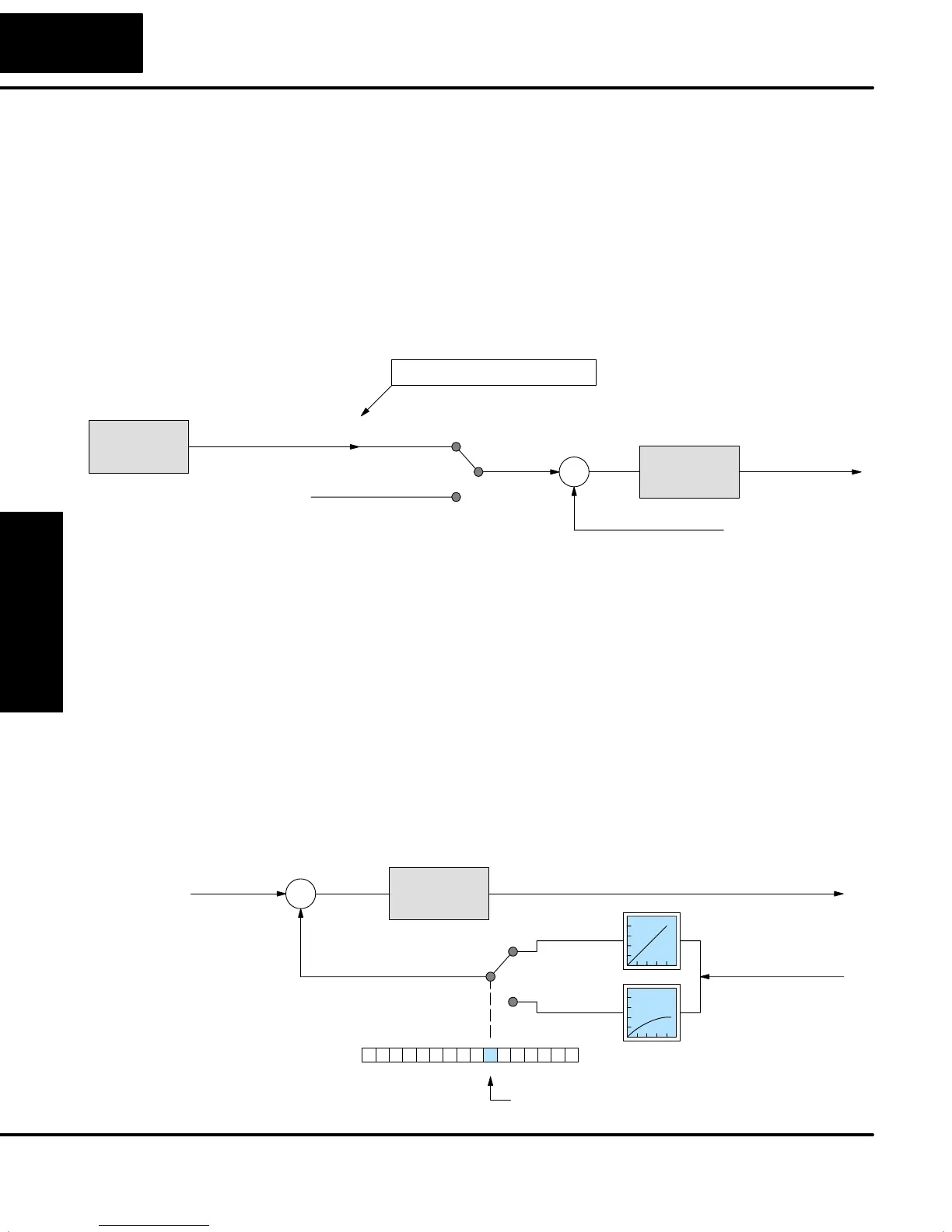

You may recall there are generally several possible data sources for the SP value.

The PID loop controller has the built-in ability to select between two sources

according to the current loop mode. Refer to the figure below. A loop reads its

setpoint from table location V+02 in Auto or Manual modes. If you plan to use

Cascade Mode for the loop at any time, then you must program its loop parameter

table with a remote setpoint pointer.

The Remote SP pointer resides in location V+32 in the loop table. For loops that will

be cascaded (made a minor loop), you will need to program this location with the

address of the major loop’s Control Output address. Find the starting location of the

major loop’s parameter table and add offset +05 to it.

Process Variable

S

+

–

Setpoint

Cascade

Auto/Manual

Control Output V+05

Normal SP V+02

Loop

Calculation

Control Output

Loop

Calculation

Cascaded loop

Another loop

Loop Table

V+32 Remote SP PointerXXXX

(minor loop)

(major loop)

A DirectSOFT32 Loop Setup dialog box will allow you to enter the Remote SP

pointer if you know the address. Otherwise, you can enter it with a HPP or program it

through ladder logic using the LDA instruction.

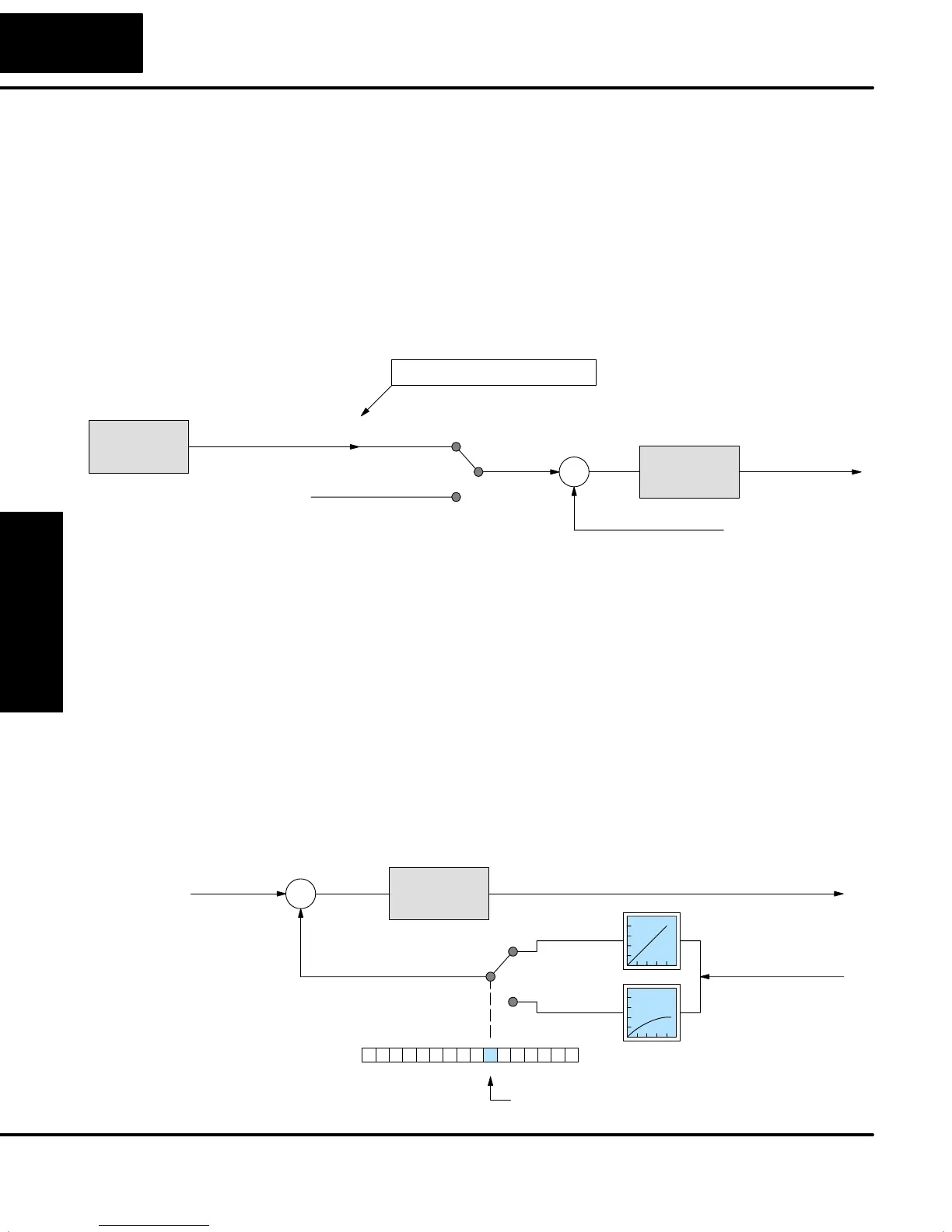

The process variable input to each loop is the value the loop is ultimately trying to

control, to make it equal to the setpoint and follow setpoint changes as quickly as

possible. Most sensors for process variables have a primarily linear response curve.

Most temperature sensors are mostly linear across their sensing range. However,

flow sensing using an orifice plate technique gives a signal representing

(approximately) the square of the flow. Therefore, a square-root extract function is

necessary before using the signal in a linear control system (such as PID).

Some flow transducers are available which will do the square-root extract, but they

add cost to the sensor package. The PID loop PV input has a selectable square-root

extract function, pictured below. You can select between normal (linear) PV data,

and data needing a square-root extract by using PID Mode setting V+00 word, bit 6.

Loop

Calculation

S

+

–

Control Output

PID Mode 1 Setting V+00

013456789101112131415 2Bit

Linear/Square-root PV select

0

1

Linear PV

Square-

root PV

Setpoint

Process Variable

Remote Setpoint

(SP) Location

Process Variable

(PV) Configuration

Loading...

Loading...