A53 Z0 9 0020 L En Technical documentation

Chapter : Dedicated I/O lines

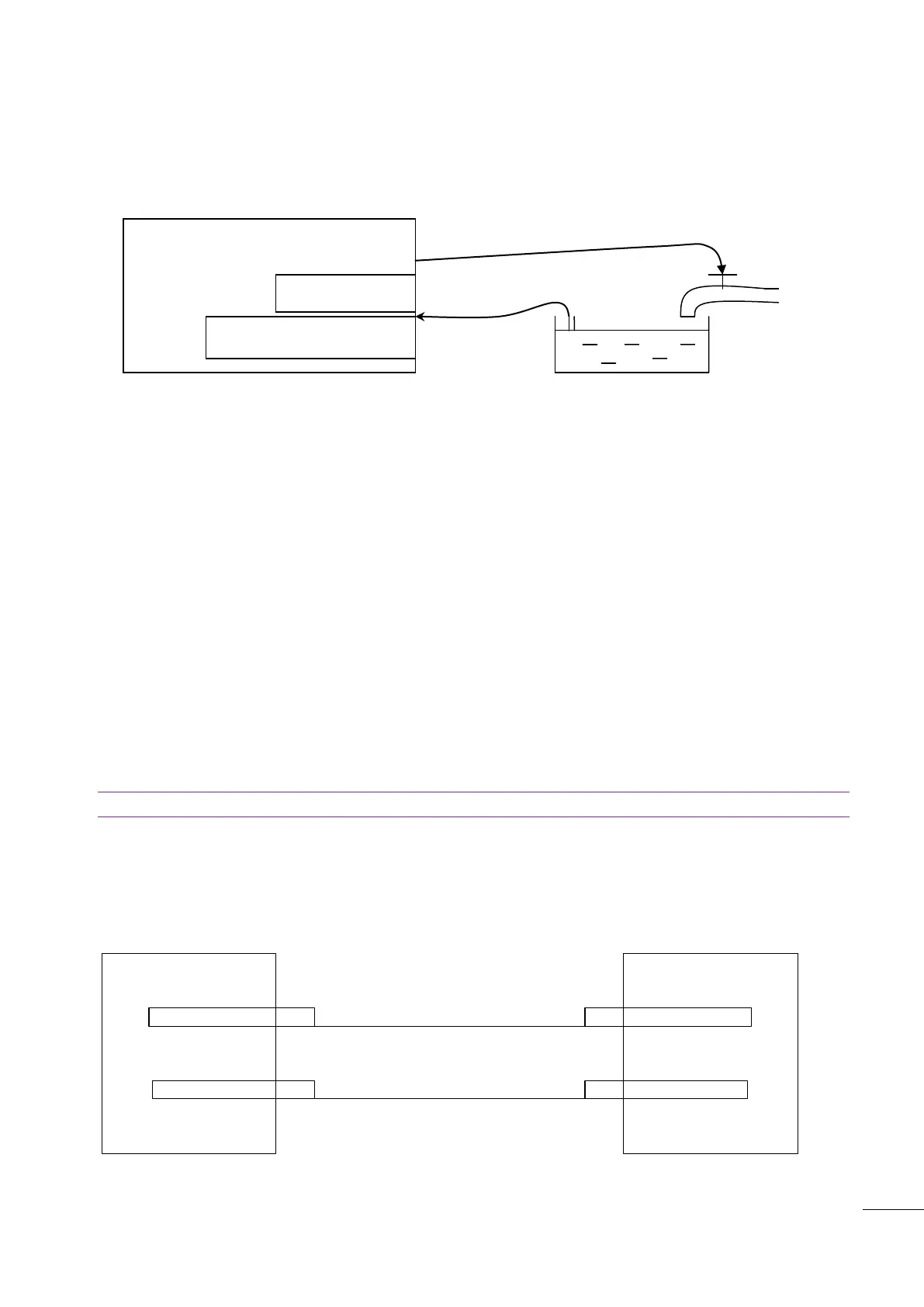

2/ Example

If the tank is fitted with a fuel level sender that can be connected to an analogue input (F1/F2 or F3/F4), it is

possible to calculate the fuel low/high limits using equations. The following example shows the case of

filling a tank. It requires filling if it is less than 20% full and filling should stop when it reaches 80% full.

Figure 53 - Filling example

E2230 is the low fuel level.

E2231 is the high fuel level.

E0031 is engine measure 1 (potentiometer input F1 / F2).

E2020 is the digital Spare output 1 which triggers the filling of the tank (C1 terminal).

PROG 1

BLOC

E2230:=E0031 LT 40;

E2231:=E0031 GT 80;

E2020:=( E2230 OR E2020) AND (!E2231)

BEND

Note : Don’t forget to configure output 1 in “Used by equations”.

10.9

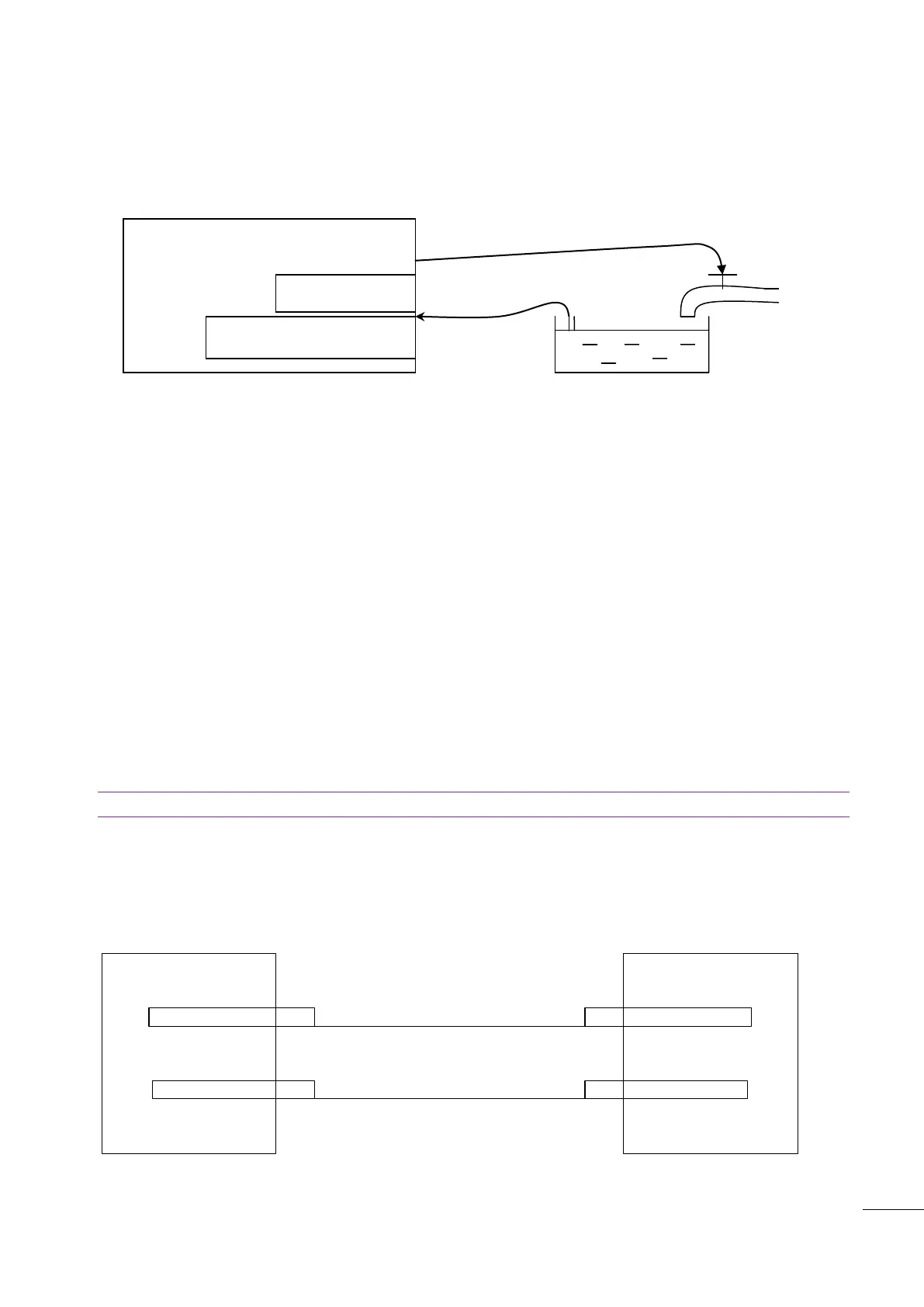

Analogue load sharing line

It is possible to use traditional analogue load sharing lines (often called Parallel lines) with the GENSYS 2.0

product. The example shown is in association with a BARBER COLMAN product.

GENSYS 2.0 BARBER COLMAN

DYN2 80108/80109

Parallel lines + Parallel lines +

Parallel lines - Parallel lines -

G6 10

G4 11

Figure 54 - Wiring parallel lines

Analogue input 1: F1 / F2

Loading...

Loading...