Manual Operation and Setup | Presetting without a 3-D touch probe

16

652

HEIDENHAIN | TNC 620 | Conversational Programming User's Manual | 10/2017

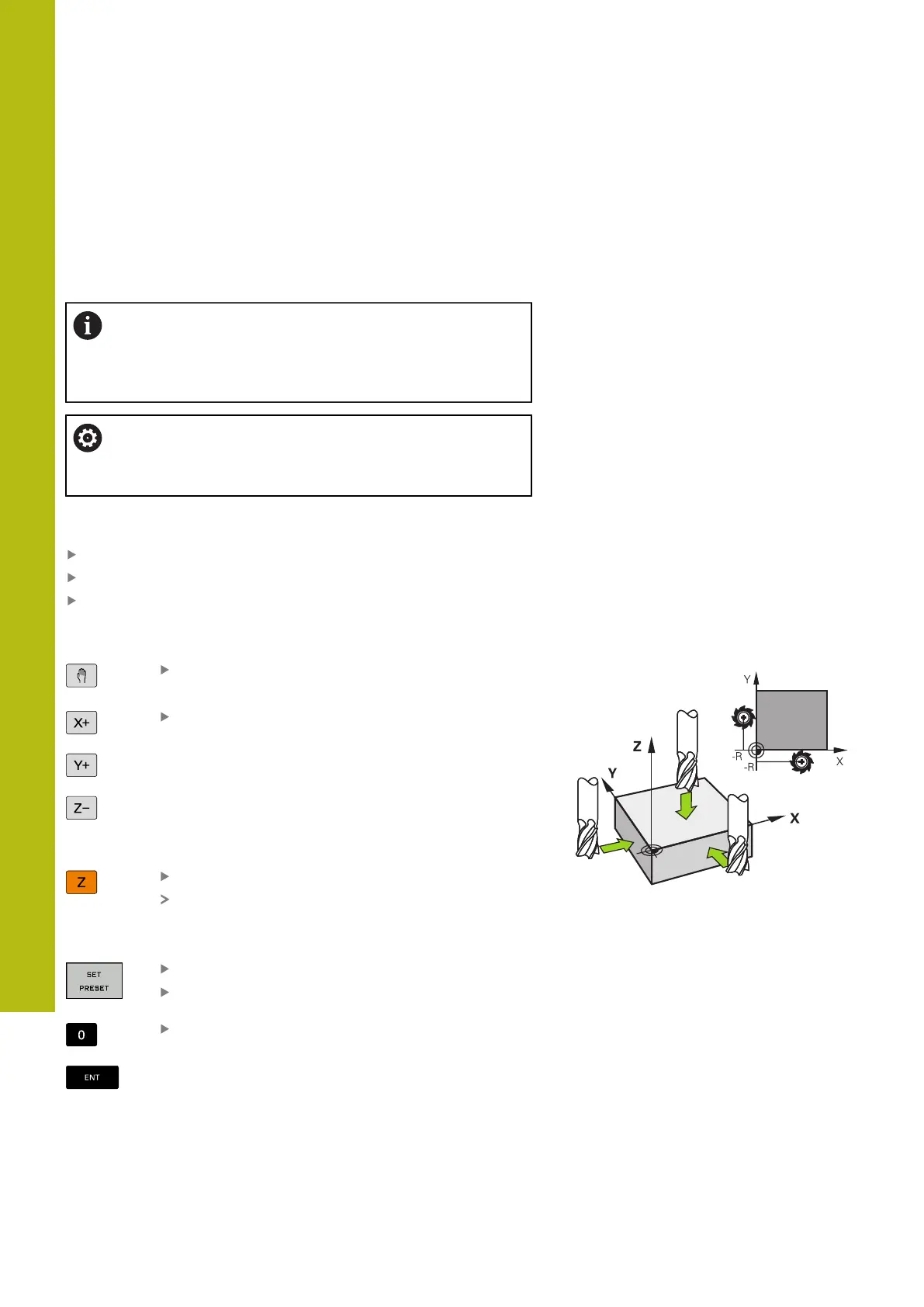

16.6 Presetting without a 3-D touch probe

Note

When presetting, you set the control display to the coordinates of a

known workpiece position.

All manual probe functions are available with a 3-D touch

probe.

Further information: "Presetting with a 3-D touch probe

(option number 17)", page 676

Refer to your machine manual.

The machine tool builder can disable presetting in

individual axes.

Preparation

Clamp and align the workpiece

Insert the zero tool with known radius into the spindle

Ensure that the control is showing the actual positions

Presetting setting with an end mill

Select the Manual operation mode

Move the tool slowly until it touches (scratches)

the workpiece surface

Setting a preset in an axis:

Select the axis

The control opens the PRESETTING Z= dialog

window

Alternative:

Press the SET PRESET soft key

Select the axis via soft key

Zero tool in spindle axis: Set the display to a

known workpiece position (here, 0) or enter the

thickness d of the shim. In the tool axis, offset

the tool radius

Repeat the process for the remaining axes.

If the tool in the tool axis has already been set, set the display of

the tool axis to the length L of the tool or enter the sum Z=L+d.

Loading...

Loading...