Manual Operation and Setup | Compensating workpiece misalignment with 3-D touch probe (option 17)

16

HEIDENHAIN | TNC 620 | Conversational Programming User's Manual | 10/2017

669

16.9 Compensating workpiece misalignment

with 3-D touch probe (option 17)

Introduction

Refer to your machine manual.

It depends on the machine whether you can

compensate workpiece misalignment with an offset

(angle for table rotation).

HEIDENHAIN only gives warranty for the function of the

probing cycles if HEIDENHAIN touch probes are used.

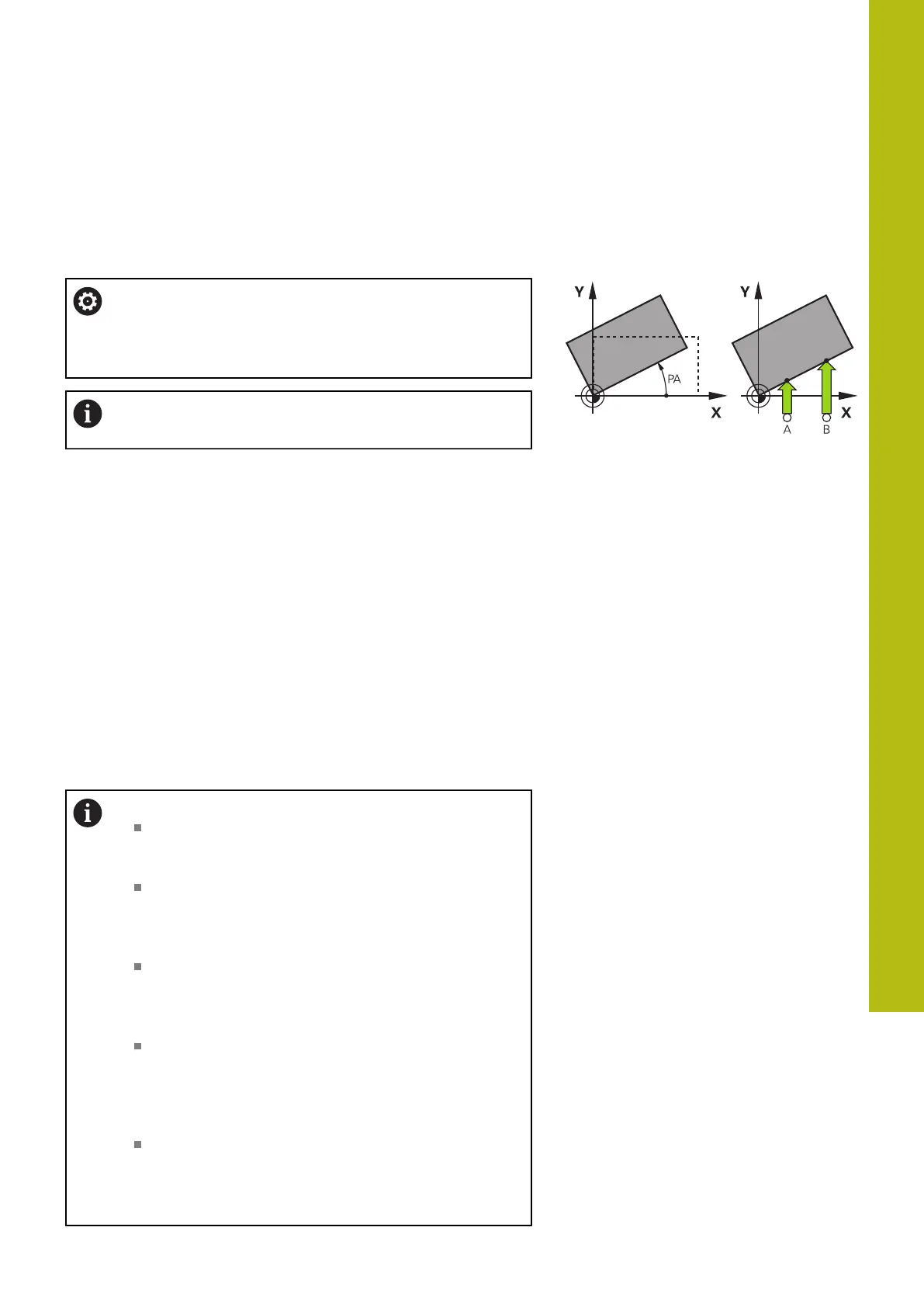

The control compensates workpiece misalignment either

mathematically by computing a basic rotation (angle of basic

rotation) or by an offset (angle for table rotation)

For this purpose, the control sets the rotation angle to the desired

angle with respect to the reference axis in the working plane.

Basic rotation: The control interprets the measured angle as

rotation around the tool direction, and saves the values in the

columns SPA, SPB, or SPC of the preset table.

Offset: The control interprets the measured angle as a shift in each

axis in the machine coordinate system, and saves the values in the

columns A_OFFS, B_OFFS, or C_OFFS of the preset table.

In order to identify the basic rotation or offset, probe two points on

the side of the workpiece. The sequence in which you probe the

points influences the calculated angle. The measured angle goes

from the first to the second probing point. You can also determine

the basic rotation or offset using holes or studs.

Operating and programming notes:

Select the probe direction perpendicular to the

angle reference axis when measuring workpiece

misalignment.

To ensure that the basic rotation is calculated

correctly during program run, program both

coordinates of the working plane in the first

positioning block.

You can also use a basic rotation in conjunction with

the PLANE function (except for PLANE AXIAL). In this

case first activate the basic rotation and then the

PLANE function.

You can also activate a basic rotation or offset

without probing a workpiece. To do so, enter a

value in the corresponding input field and press the

SET BASIC ROTATION or SET TABLE ROTATION soft

key.

The behavior of the control during presetting

depends on the setting in the machine parameter

chkTiltingAxes (no. 204601).

Further information: "Introduction", page 654

Loading...

Loading...