Positioning with Manual Data Input | Programming and executing simple machining operations

17

696

HEIDENHAIN | TNC 620 | Conversational Programming User's Manual | 10/2017

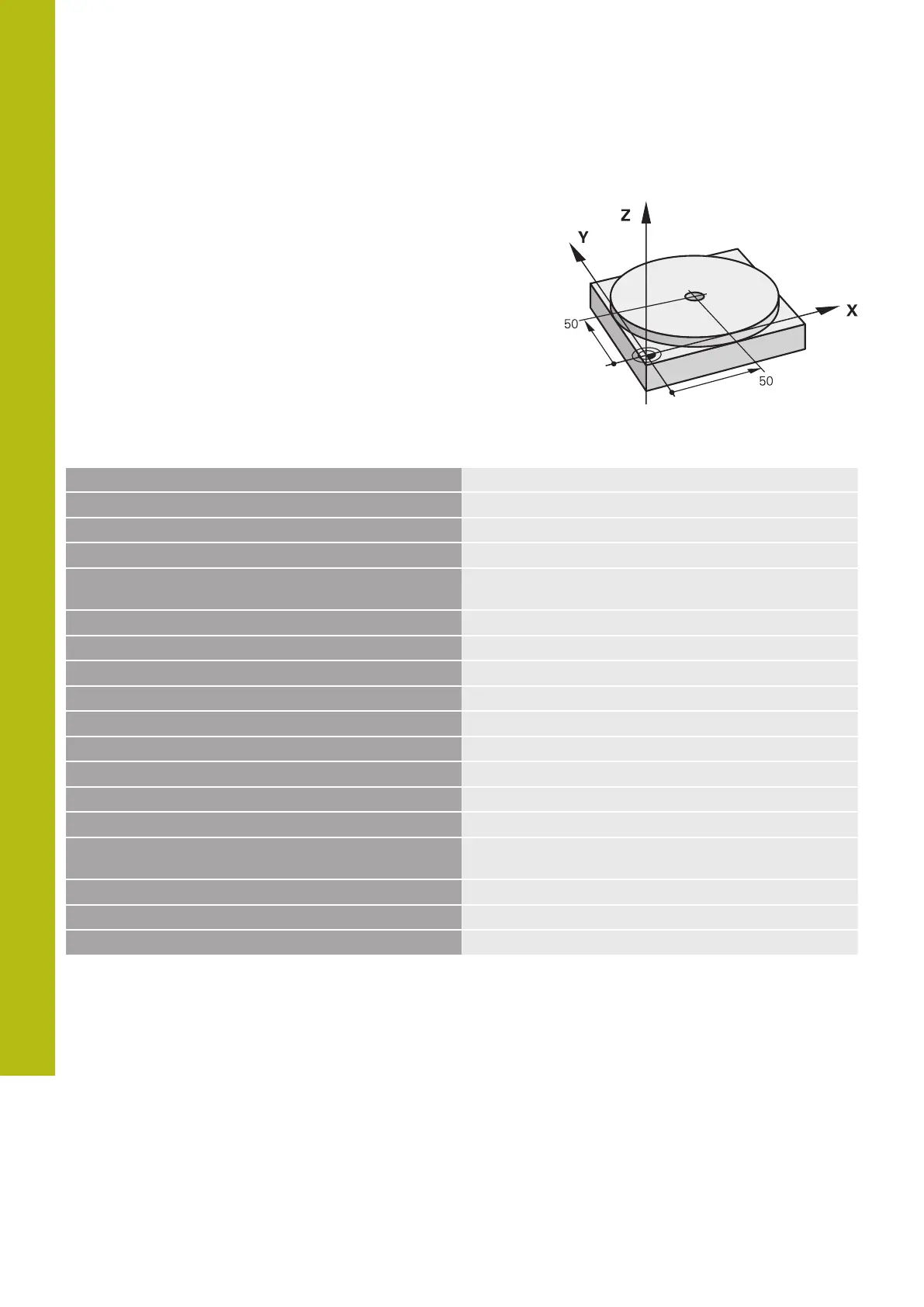

Example

A hole with a depth of 20 mm is to be drilled into a single

workpiece. After clamping and aligning the workpiece and setting

the preset, you can program and execute the drilling operation with

a few lines of programming.

First you pre-position the tool above the workpiece with straight-

line blocks and position with a safety clearance of 5 mm above the

hole. Then drill the hole with Cycle 200 DRILLING.

0 BEGIN PGM $MDI MM

1 TOOL CALL 1 Z S2000

Call the tool: tool axis Z,

spindle speed 2000 rpm

2 L Z+200 R0 FMAX

Retract the tool (F MAX = rapid traverse)

3 L X+50 Y+50 R0 FMAX M3

Move the tool at F MAX to a position above the hole, spindle

on

4 CYCL DEF 200 DRILLING

Define the DRILLING cycle

Q200=5 ;SET-UP CLEARANCE

Set-up clearance of the tool above the hole

Q201=-20 ;DEPTH

Hole depth (algebraic sign=working direction)

Q206=250 ;FEED RATE FOR PLNGNG

Feed rate for drilling

Q202=5 ;PLUNGING DEPTH

Depth of each infeed before retraction

Q210=0 ;DWELL TIME AT TOP

Dwell time after every retraction in seconds

Q203=-10 ;SURFACE COORDINATE

Coordinate of the workpiece surface

Q204=20 ;2ND SET-UP CLEARANCE

Set-up clearance of the tool above the hole

Q211=0.2 ;DWELL TIME AT DEPTH

Dwell time in seconds at the hole bottom

Q395=0 ;DEPTH REFERENCE

Depth referenced to the tool tip or the cylindrical part of the

tool

5 CYCL CALL

Call the DRILLING cycle

6 L Z+200 R0 FMAX M2

Retract the tool

7 END PGM $MDI MM

End of program

Straight-line function:

Further information: "Straight line L", page 289

Loading...

Loading...