2F-4 –MIE MODELS - HURTH TRANSMISSION 90-823225--1 1096

!

CAUTION

Center lifting eye (located on top of thermostat

housing) is used for engine alignment only. DO

NOT use to lift entire engine.

!

CAUTION

DO NOT allow lifting sling to hook or compress

engine components or damage to them will oc-

cur.

2. Attach a suitable sling to lifting eyes on engine.

(Refer to “Removal” section for location of

lifting eyes.)

IMPORTANT: Engine bed must position engine

so that a minimum of 1/4 in. (6 mm) up-and-down

adjustment still exists on all four mounts after

performing final alignment. This is necessary to

allow for final engine alignment.

3. Lift engine into boat and position on engine bed

so that transmission output flange and propeller

shaft coupler are visibly aligned (no gap can be

seen between coupling faces when butted to-

gether). Adjust engine bed height, if necessary,

to obtain proper alignment. DO NOT use mount

adjustments to adjust engine position at this time.

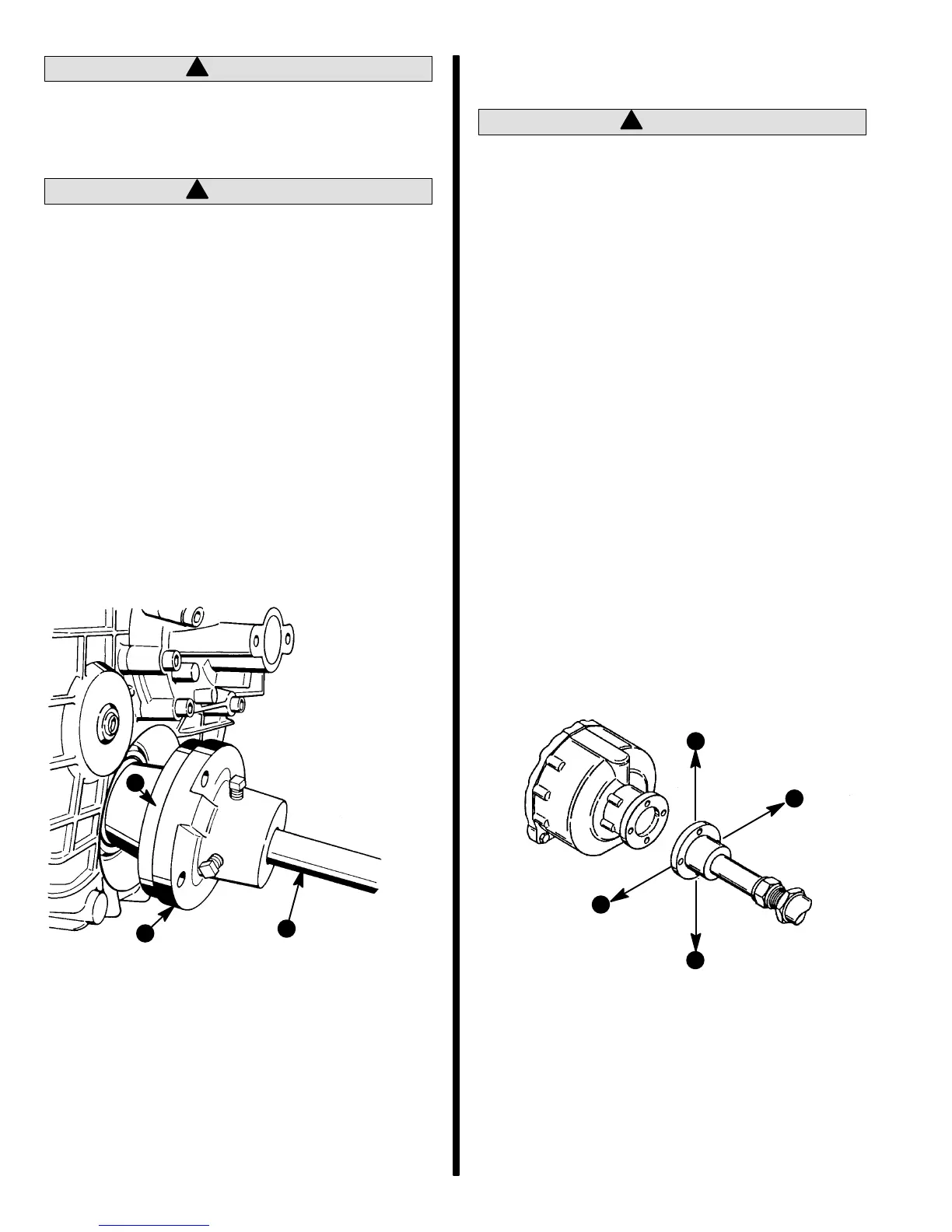

72596

a

b

c

a - Propeller Shaft

b - Propeller Shaft Coupler

c - Transmission Output Flange

4. Check all four mounts to ensure that they are still

positioned properly, then fasten mounts to en-

gine bed with appropriate bolts or lag screws and

hardware. Tighten lag bolts/screws securely.

5. Disconnect and remove sling. Proceed to “En-

gine Final Alignment” section following.

Engine Final Alignment

!

CAUTION

To avoid vibration, noise and damage to trans-

mission output shaft oil seal and bearings, en-

gine must be properly aligned.

IMPORTANT: Engine alignment MUST BE RE-

CHECKED with boat in the water, fuel tanks filled

and with a normal load on board.

Engine must be aligned so that transmission output

flange and propeller shaft coupler centerlines are

aligned and coupling faces are parallel within .003 in.

(0.07mm). This applies to installations with solid cou-

plings, as well as flexible couplings.

1. Check mating surfaces on transmission output

flange and propeller shaft coupler faces to make

sure they are clean and flat.

2. Center propeller shaft in shaft log as follows:

a. Push down and then lift shaft as far as it will

move. Then place shaft in the middle of the

movement.

b. Move shaft to port and then to starboard as

far as shaft will move. Then place shaft in the

middle of the movement.

c. With shaft in center of shaft log, as deter-

mined by above procedures “a” and “b,” align

engine to shaft.

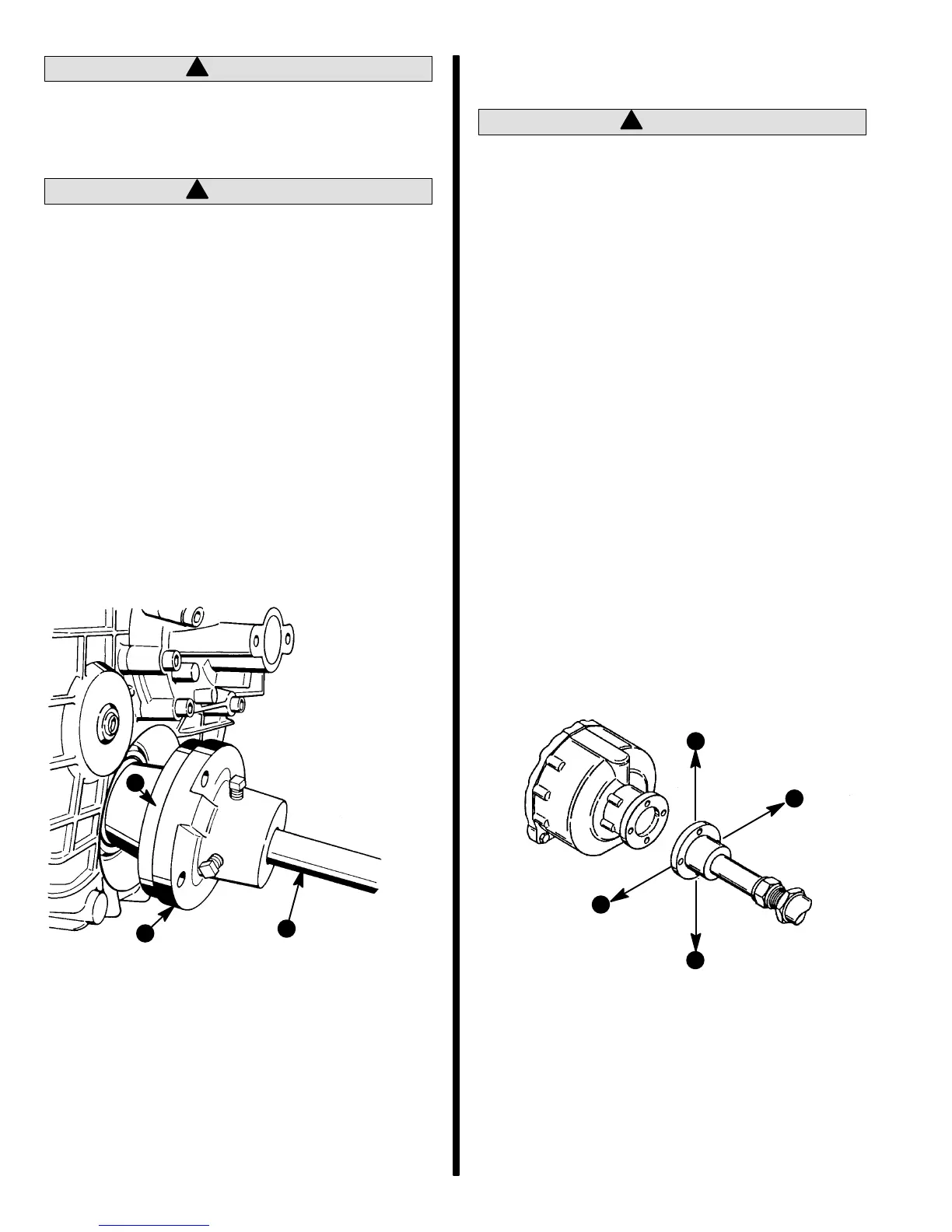

a-Up

b - Down

c - Port

d - Starboard

72595

b

c

d

a

Loading...

Loading...