MAINTENANCE - 1B-1790-823225--1 1096

Filling and Bleeding Power

Steering System

IMPORTANT: Power steering system must be

filled exactly as explained in the following to be

sure that all air is bled from the system. All air

must be removed, or fluid in pump may foam dur-

ing operation and be discharged from pump res-

ervoir. Foamy fluid also may cause power steer-

ing system to become spongy, which may result

in poor boat control.

1. With engine stopped, position drive unit so that it

is straight back. Remove fill cap/dipstick from

power steering pump. Add Quicksilver Power

Trim and Steering Fluid or automatic transmis-

sion fluid (ATF), Dexron, or Dexron II, as re-

quired, to bring level up to FULL COLD mark on

dipstick.

IMPORTANT: Use only Quicksilver Power Trim

and Steering Fluid or automatic transmission

fluid (ATF), Dexron, or Dexron II in power steering

system.

2. Turn steering wheel back and forth to end of trav-

el in each direction several times, then recheck

fluid level and add fluid, if necessary.

3. Install vented fill cap.

!

CAUTION

DO NOT operate engine without water being

supplied to seawater pickup pump, or pump im-

peller may be damaged and subsequent over-

heating damage to engine may result.

4. Start engine and run at fast idle (1000-1500

RPM) until engine reaches normal operating

temperature. During this time, turn steering

wheel back and forth to end of travel in each di-

rection several times.

5. Position drive unit so that it is straight back and

stop engine. Remove fill cap from pump. Allow

any foam in pump reservoir to disperse, then

check fluid level and add fluid, as required, to

bring level up to FULL HOT mark on dipstick. DO

NOT OVERFILL. Reinstall fill cap securely.

IMPORTANT: Drive unit must be positioned

straight back and power steering fluid must be

hot to accurately check fluid level.

6. If fluid is still foamy (in Step 5), repeat Steps 4 and

5 until fluid does not foam and level remains con-

stant.

Maintaining Closed Cooling

Coolant Level

!

WARNING

Allow engine to cool down before removing pres-

sure cap. Sudden loss of pressure could cause

hot coolant to boil and discharge violently. After

engine has cooled, turn cap 1/4 turn to allow any

pressure to escape slowly, then push down and

turn cap all the way off.

1. Coolant level in heat exchanger should be full (to

bottom of filler neck).

IMPORTANT: When reinstalling pressure cap, be

sure to tighten it until it contacts stop on filler

neck.

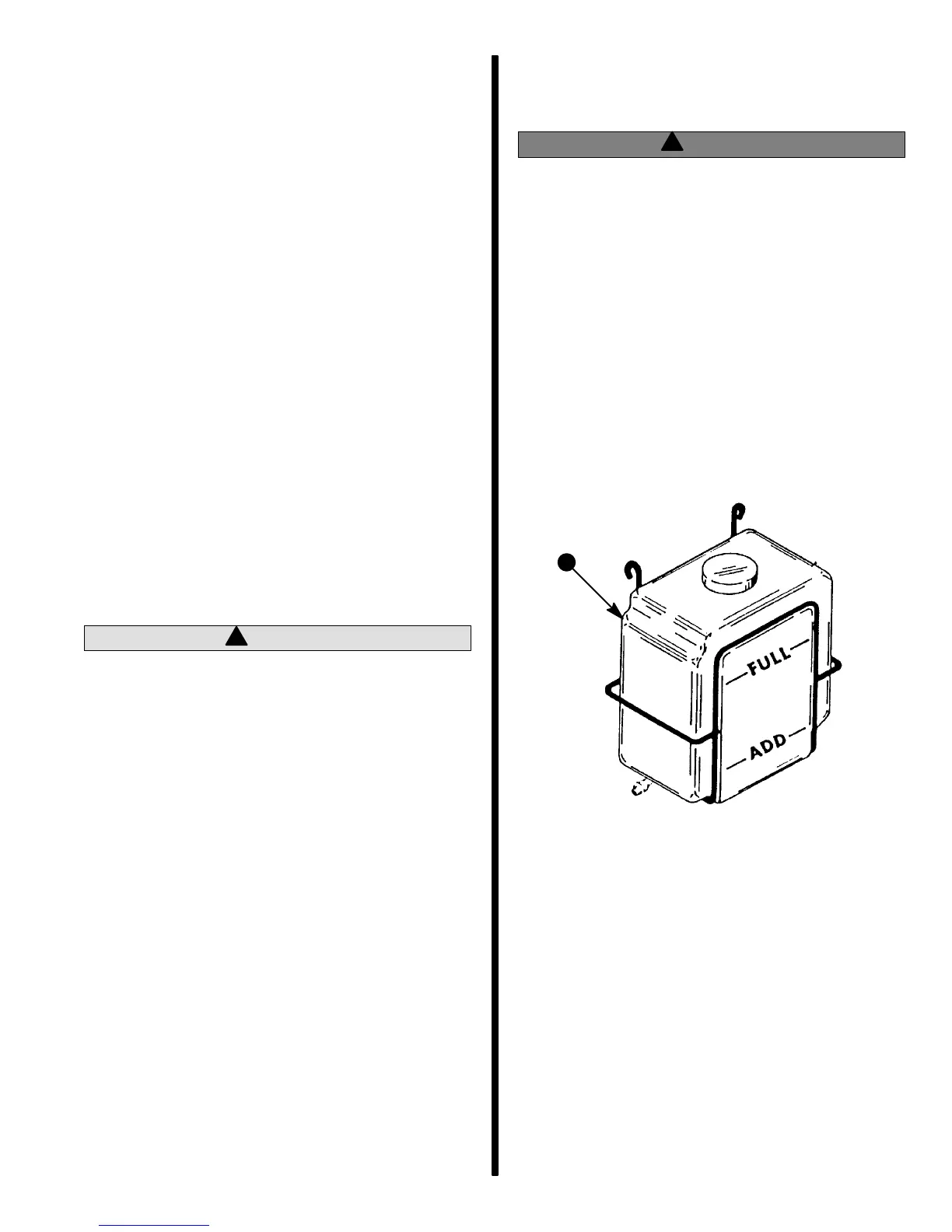

2. Coolant level should be between the ADD and

FULL marks on coolant recovery reservoir with

the engine at normal operating temperature.

72520

a

a - Coolant Recovery Reservoir

Flushing Cooling System

If engine is operated in salty, polluted, or mineral-lad-

en water, flush cooling system (preferably after each

use) to reduce corrosion and prevent the accumula-

tion of deposits in the system. Thoroughly flush cool-

ing system prior to storage.

Loading...

Loading...