6B-40 - CLOSED COOLING MODELS 90-823225--1 1096

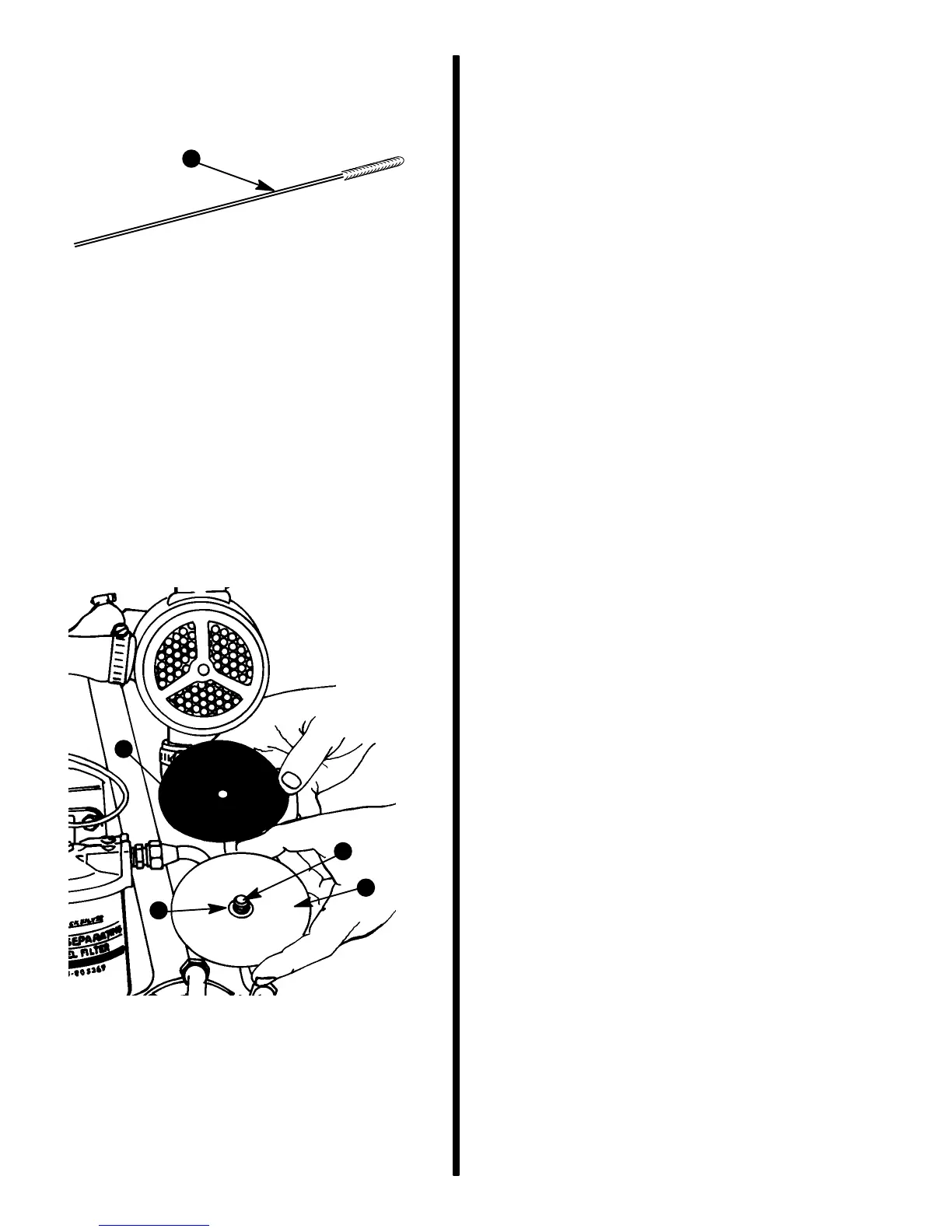

6. Clean tubes (passages) in heat exchanger and

coolers by running a suitable wire brush through

each tube.

71724

a

a - Wire Brush, Sized To Fit Passage

7. Rinse out heat exchanger and fluid cooler tubes

with tap water from a hose to remove loosened

particles.

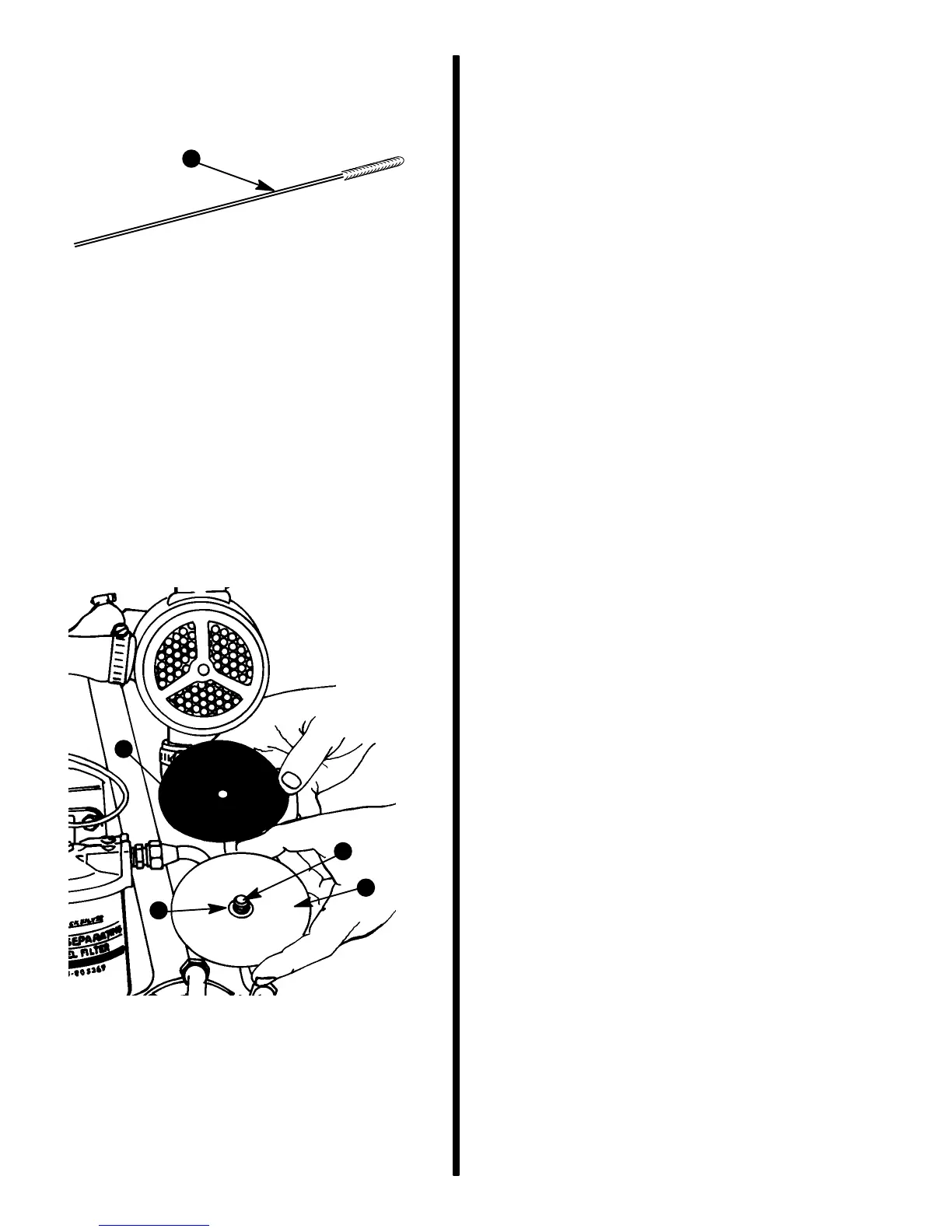

8. Install end covers on heat exchanger as follows:

a. Clean gasket mating surfaces on end covers

of heat exchanger.

b. Inspect gaskets and O-rings for damage and

replace if necessary.

c. Reinstall end covers with components

shown. Torque end cover screws to 1 to 1-1/2

turns past hand tight.

71515

b

d

a

c

a - End Cover (Heat Exchanger)

b - Screw

c - O-ring

d - Rubber Gasket

9. Install all hoses previously disconnected . Tight-

en hose clamps securely.

10. Start engine and check for leaks.

Cleaning Closed Cooling Section

Closed Cooling section of cooling system should be

cleaned whenever decreased cooling efficiency (due

to internal deposits) is experienced.

A good grade automotive cooling system cleaning

solution, that is compatible with copper and cast iron

may be used to remove rust, scale or other foreign

material. Manufacturer’s instructions of particular

cleaner being used, should be carefully followed to

ensure a safe and effective cleaning operation.

If coolant section is extremely dirty, a pressure

flushing device may be used to flush out remaining

deposits. Flushing should be done in direction

opposite normal coolant flow (with thermostat re-

moved) to allow water to reach behind deposits and

force them out (refer to “Cooling System Water Flow

Diagram,” following). Follow instructions which ac-

company flushing device for proper hookup and

flushing procedure.

Loading...

Loading...