8A-6 - VELVET DRIVE IN-LINE TRANSMISSION 90-823225--1 1096

4. Check oil for the following foreign matter:

• Metal Particles - A few small particles are

normal. Larger metal chips are an early sign

of transmission failure which may mean

transmission should be disassembled and in-

spected for internal damage.

• Rubber Particles - Indication of cooler hose

wear. Hoses should be inspected for cracks

or fraying. Replace damaged hoses.

!

CAUTION

Avoid severe transmission damage or possible

failure of transmission. Strainer must be properly

installed as follows.

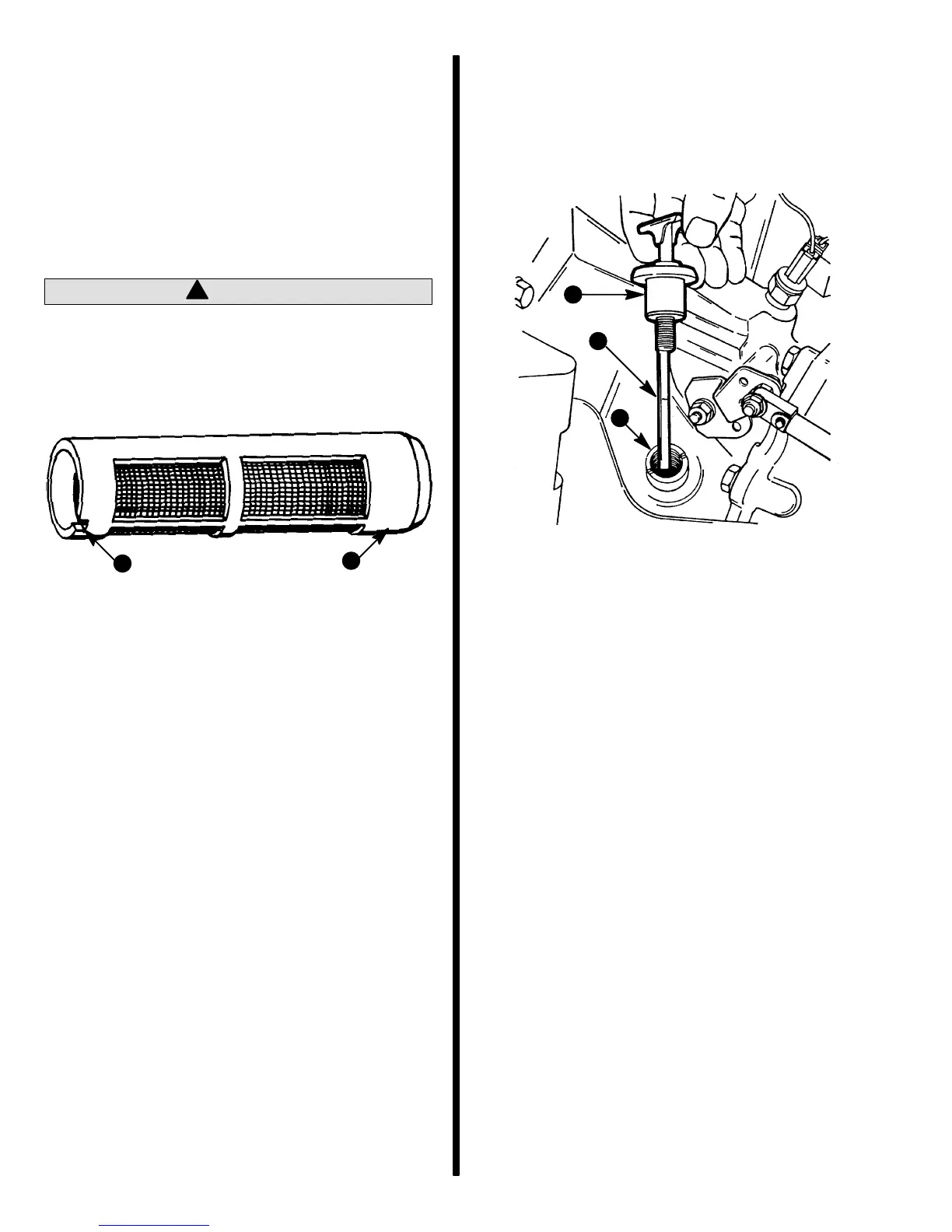

5. Install plastic strainer tube with the notch DOWN

and OUT toward the side of the case.

71306

b

a

a - Plastic Strainer Tube

b - Notch

6. Install spring.

7. Coat bushing threads with Quicksilver Perfect

Seal. Install and torque bushing to 25 lb. ft.

(34 N·m).

8. Coat elbow fitting threads with Quicksilver Per-

fect Seal and install in bushing. Tighten securely.

9. Reconnect hose and tighten securely.

Filling Transmission

IMPORTANT: Use only specified transmission

fluid (see “Specifications”).

1. Remove dipstick. Fill transmission with fluid,

through dipstick hole, to bring up to full mark.

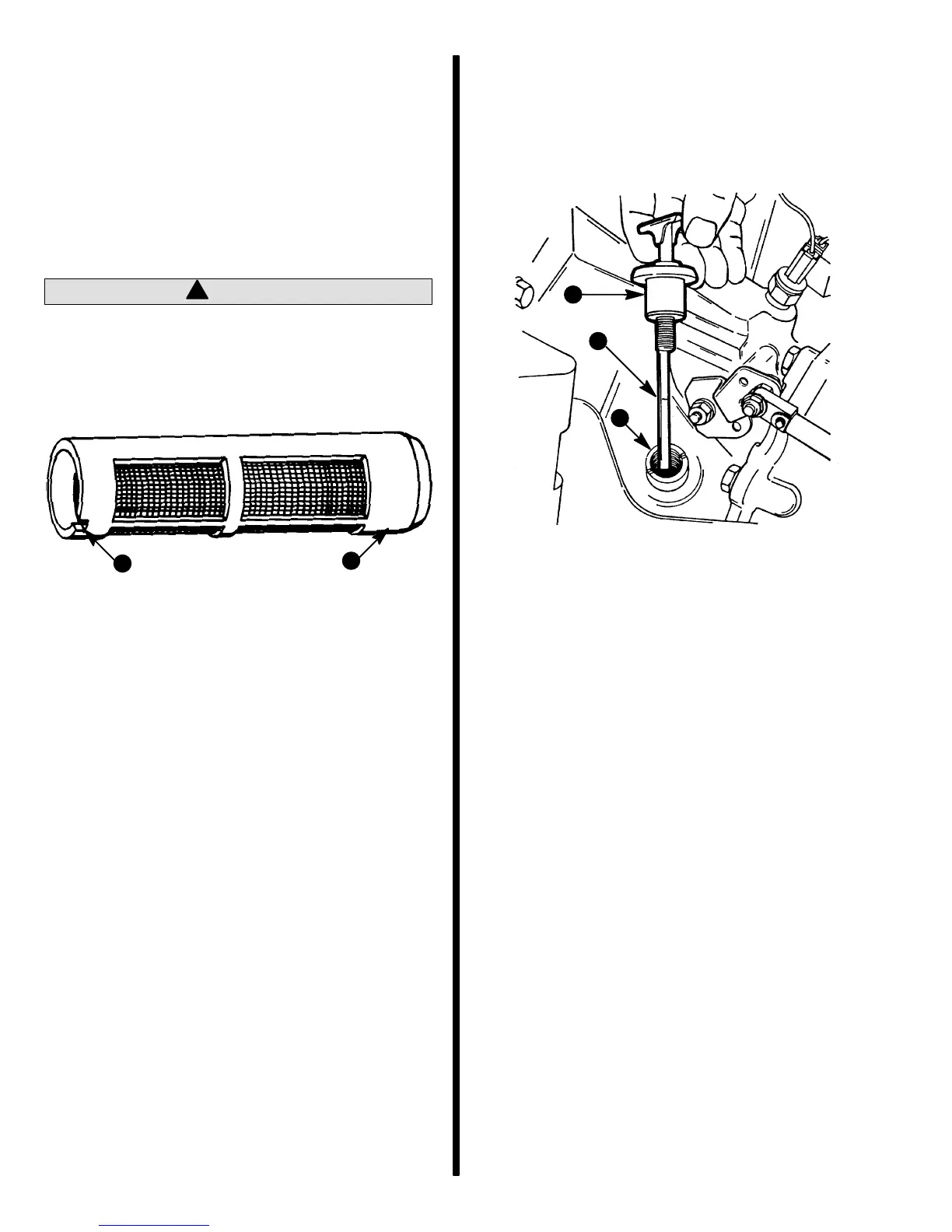

72526

b

c

a

a - Dipstick

b - Full Mark

c - Dipstick Tube

IMPORTANT: To accurately check fluid level, run

engine at 1500 RPM for 2 minutes immediately

prior to checking level.

2. Start engine and run at 1500 RPM for 2 minutes

to fill all hydraulic circuits.

NOTE: Be sure to push dipstick all the way down into

dipstick tube when checking fluid level.

3. Stop engine and quickly check fluid level. Add

transmission fluid, if necessary, to bring level up

to full mark on dipstick.

4. Reinstall dipstick. Be sure to tighten T-handle

securely.

Loading...

Loading...