6B-28 - CLOSED COOLING MODELS 90-823225--1 1096

1. Remove seawater drain plug from bottom of heat

exchanger and allow water to drain. After water

has drained completely, coat threads of drain

plug with Quicksilver Perfect Seal and reinstall.

72718

b

c

d

a

e

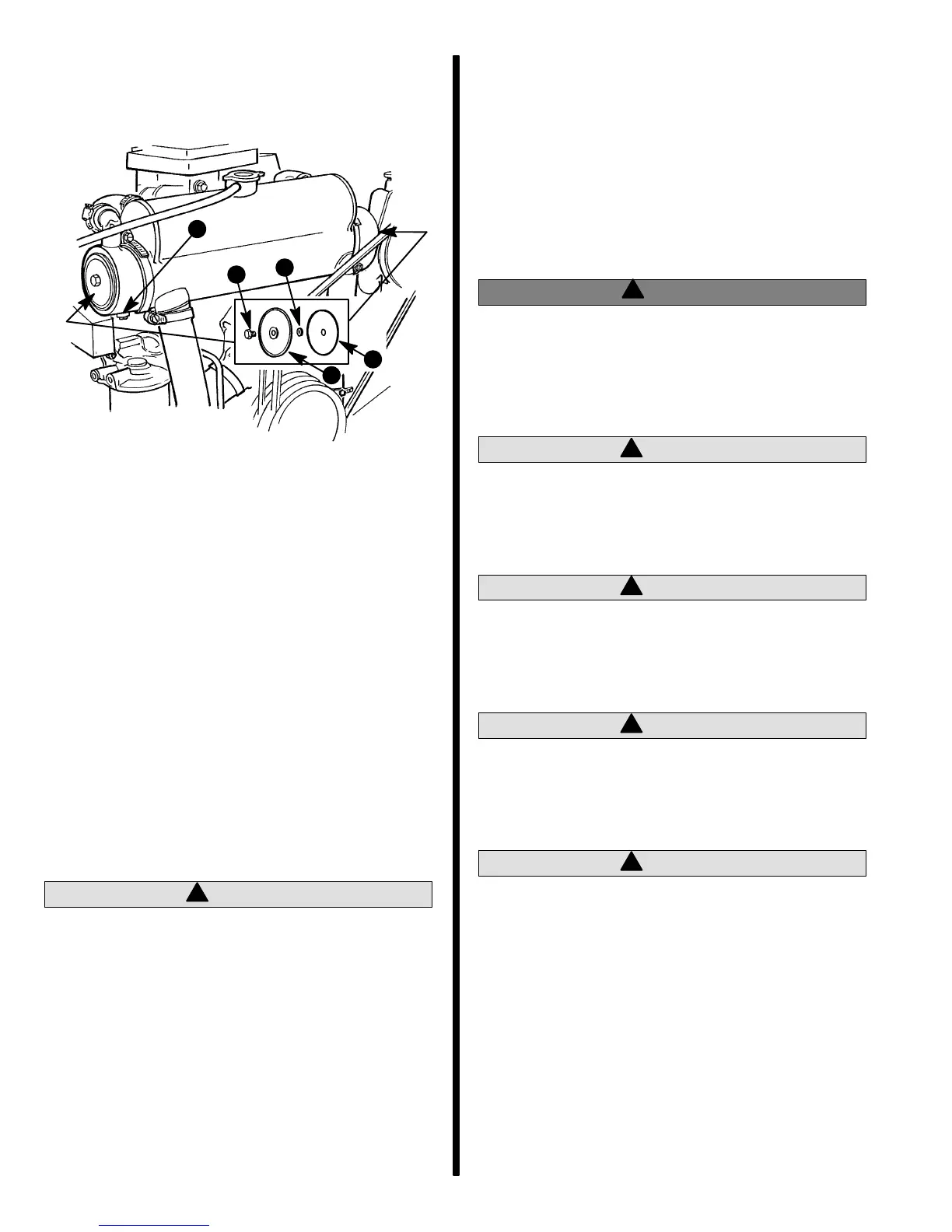

a - Bolt

b - End Cap

c - Sealing Washer

d - Gasket

e - Drain Plug

2. Remove bolts which secure end plates to each

end of heat exchanger, then remove end plates,

seal washers and gaskets. Discard seal washers

and gaskets. Clean gasket material from end

plates and heat exchanger.

3. Clean water passages in heat exchanger by in-

serting a suitable size wire brush into each pas-

sage. Use compressed air to blow loose particles

out of water passages.

4. Apply Quicksilver Perfect Seal to both sides of

new end plate gaskets, then reinstall end plates,

using new gaskets and seal washers. (Be sure to

install seal washers between end plates and gas-

kets.) Torque end plate bolts to specifications.

!

CAUTION

Avoid seawater pickup pump impeller damage.

DO NOT operate engine without water being

supplied to seawater pickup pump.

5. With boat in the water and/or cooling water prop-

erly supplied to seawater pickup pump, start en-

gine and inspect for leaks.

Flushing Seawater Section

of Closed Cooling System

If engine is operated in salty, polluted or mineral-

laden waters, seawater section of closed cooling

system should be flushed periodically (preferably

after each use) with fresh water to reduce corrosion

and prevent the accumulation of deposits in the

system. Seawater section also should be thoroughly

flushed prior to storage.

!

WARNING

When flushing cooling system with boat out of

the water, be certain that area in vicinity of pro-

peller is clear and that no person is standing

nearby. As a precautionary measure, it is recom-

mended that propeller be removed.

!

CAUTION

Do not run engine above 1500 RPM when flush-

ing. Suction created by seawater pickup pump

may collapse flushing hose, causing engine to

overheat.

!

CAUTION

If cooling system is to be flushed with boat in the

water, seacock (if so equipped) must be closed,

or water inlet hose must be disconnected and

plugged to prevent water from flowing into boat.

!

CAUTION

To prevent engine or stern drive unit damage

DO NOT run engine or drive unit without water

being supplied to water intake openings on gear

housing.

!

CAUTION

Watch temperature gauge at dash to ensure the

engine does not overheat.

1. Follow instructions appropriate to your model:

NOTE: If flushing cooling system with boat in water,

raise drive unit to trailer position, install flushing at-

tachment and lower drive unit to full IN/DOWN posi-

tion.

Loading...

Loading...